7 in, Nitial pow, Wer up a – Pulsafeeder Polyfeeder EN User Manual

Page 21: And syste, Em oper, Ation

6.7 In

U

st

po

co

6.7.1 P

6.7.1.1

T

an

pu

th

6.7.1.2

T

bl

se

th

6.7.1.3

T

th

co

B

co

S

F

sw

an

6.7.2 U

The follow

necessary

nitial Pow

Upon initial po

tart-up screen

osition. Once

onfigurability

Polyfeeder

Local Mode

The first oper

nd adjusted

ush button a

he system in

Remote Sta

he second con

lending system

etpoint is set l

his mode of op

Remote Sta

The third con

his mode, the

ontact input.

By providing

ontrol the po

CADA/PLC

or safety pu

witch. All

nd setup par

User Inter

wing table, us

y key press seq

wer Up a

ower applicati

n sequence. T

e the start-up

y via the progr

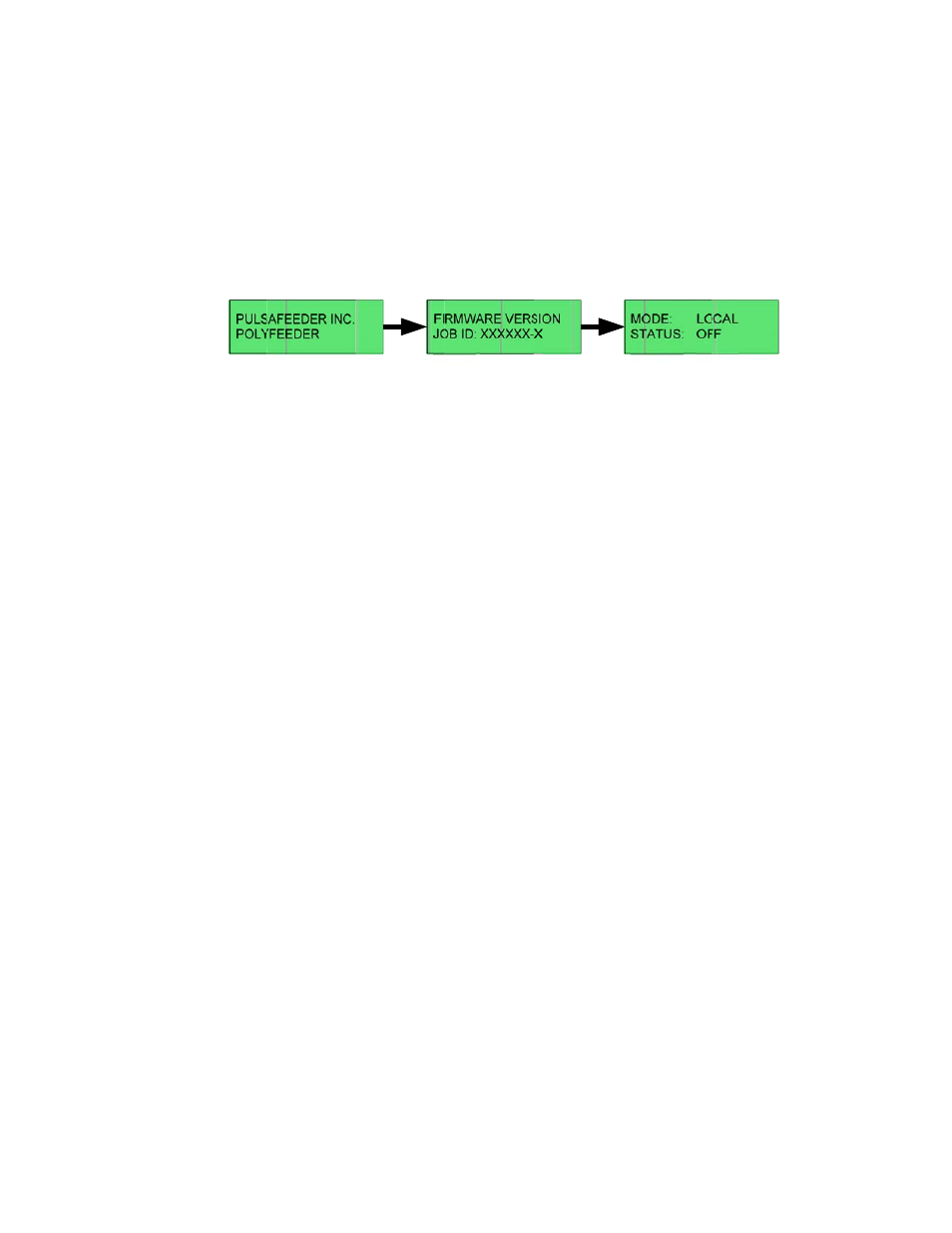

Figure 6

r B and B

e

rational mod

from the “Lo

and placing t

this mode.

art/Stop Mo

ntroller opera

m from a rem

locally and us

peration.

art/Stop Mo

ntroller opera

e polymer m

.

a remote an

olymer conce

C system can

urposes the s

operating pa

rameters are

rface Desc

sed with Figur

quences to pro

and Syste

ion to the poly

The sequence s

sequence has

ramming inte

6-7 Polyfeeder

++ Modes

de is “Local O

ocal” contro

the mode sel

ode

ational mode,

motely located

sed when rem

ode with An

ational mode

mixing system

nalog input s

entration (po

n be provided

ystem may b

arameters, su

still changed

ription an

re 6-7-2, desc

ovide functio

21

em Oper

ymer mixing

show is when

s been comple

rface can occ

r Controller S

s of Opera

Only.” All f

ol panel inter

ector switch

remote start s

d PLC/SCADA

motely started.

alog Concen

e is Remote S

m is started a

ignal, the Re

olymer pump

d an analog f

be shut dow

uch as diluti

d locally at t

nd System

cribes where a

nality.

ation

system the co

n the system m

eted and electr

cur.

Start Up Scree

ation

functions rel

rface via ope

h to PUMP O

stop, allows th

A or remote s

The analog

ntration Co

Start Stop M

and stopped

emote Start/

p pacing). W

feedback pro

wn locally, us

ion water flo

the control p

Operation

and how to pe

ontroller LCD

mode selector

trical installati

en Sequence

lated to the s

erator input.

OFF are the t

he user to star

switch. In thi

input must be

ontrol

Mode with A

from a remo

/Stop mode c

While in this

oportional to

sing the PUM

ow rate, both

panel interfac

n

erform system

D will report th

r switch is in t

ion completed

system are c

The System

two ways to

rt or stop the

s mode, the c

e de-activated

nalog contro

ote location u

can automati

s mode, the u

o polymer flo

MP OFF mo

h primary an

ce.

m operations a

he basic

the local

d, system

ontrolled

m start/stop

start/stop

polymer

oncentration

d to enable

ol . While in

using a dry

ically

user’s

ow rate.

ode selection

nd secondary

and the

n

n

y