1 neat polymer feed pump, 2 mix chamber motor shaft seal – Pulsafeeder Polyfeeder EN User Manual

Page 40

40

7.1 Neat Polymer Feed Pump

Refer to the attached manual for the neat polymer feed pump supplied with your PolyFeeder system.

Follow the operation and maintenance guidelines within.

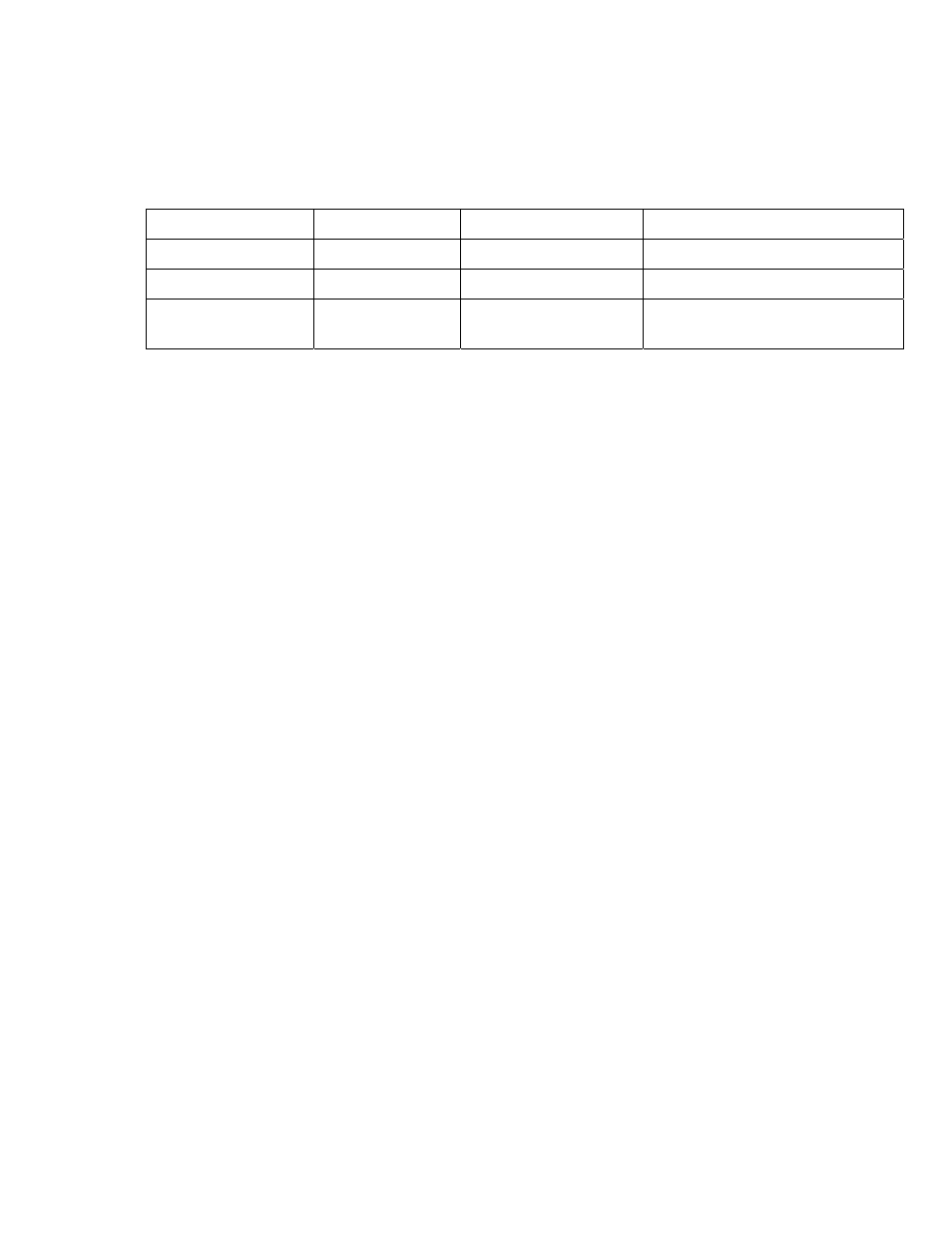

Pump Technology

Flow Rate Range

Manufacturer

Model(s) Available

Solenoid Diaphragm

0.5 – 10 GPH

Pulsafeeder (Pulsatron)

LVB, LVF, LVG, LVH

Gear

Pulsafeeder (Eco)

GMC1, GC2, GC4

Progressing Cavity

Seepex

5-24 MD, 15-24 MD, 3-12 MD

6-12 MD, 12-12 MD

7.2 Mix Chamber Motor Shaft Seal

Check the slot area between the mix chamber motor and the mix chamber. If there is evidence of

excessive product leakage in this area, the seal should be replaced.

If the mix chamber motor shaft seal needs replacement, follow these steps:

1. Shut off the polymer pump and mix chamber motor at the main control panel and lock out the power.

2. Close the dilution water inlet valve.

3. Drain the mix chamber by opening the Mix chamber drain valve.

4. Unbolt the motor side chamber mounting bracket from the skid frame (2 bolts).

5. Unbolt the motor from the rear of the mix chamber by removing the 8 hex nuts from the mix chamber

tie rods.

6. If desired, the motor could be unwired at its conduit box and be taken to a bench, or tipped onto its fan

cover and worked on at the skid location without requiring electrical disconnection (provided power is

off/ locked out and some means of securing the motor from dropping off the skid is present).

7. The seal is held in place by the mixing impeller and a hex nut threaded on the end of the motor shaft.

8. Unbolt the mixing impeller from the motor shaft (there is a slot in the back of the motor shaft to hold it

from turning – alternately one can get an open end wrench onto the hex nut underneath the impeller

and hold it that way.

9. Unbolt the hex nut under the impeller

10. Remove the spring retainer and seal spring

NOTE: It is recommended to replace the ENTIRE seal (head and seat) as an assembly, rather than

merely a head or seat alone.

11. Remove the seal head

12. Remove the seal seat (TEFC Motor plate can be unbolted from motor to facilitate this, simply remove

the four (4) 3/8” socket head motor mounting screws)

13. Inspect motor shaft for damage, repair/ replace if necessary.

14. Carefully replace the seal seat and head with new ones. Take particular care when installing the new

seal head - and its elastomeric sleeve – over the threaded end and shoulder of the motor shaft.

15. Reassemble the mix chamber in reverse order from how it was disassembled – Please note that the

motor capacitor should be “up” and the slot between the mix chamber and the motor should be

“down” when finished.