1 connecting inlet and outlet piping – Pulsafeeder Polyfeeder EN User Manual

Page 13

13

Tools Required: Pipe Wrenches (for inlet/outlet connections)

Flat Bladed Screwdriver (for adjusting backpressure / relief valves)

Tools Recommended: Pocket Calculator & Stopwatch (for calibrating polymer flow rate)

6.5.1 Connecting Inlet and Outlet Piping

6.5.1.1 Initial Valve Settings

It is highly recommended at this point that the system be electrically wired and power applied. Elements

of startup require startups of the system.

First, close all inlet, outlet, bleed and isolation valves. Depending on system configuration, there can be

up to eleven (11) of these valves in the system, and these are either ball valves or globe valves.

The input water regulator, located very close to the water inlet, needs to be turned fully clockwise

looking at it from the top, in order to guarantee no water flow on

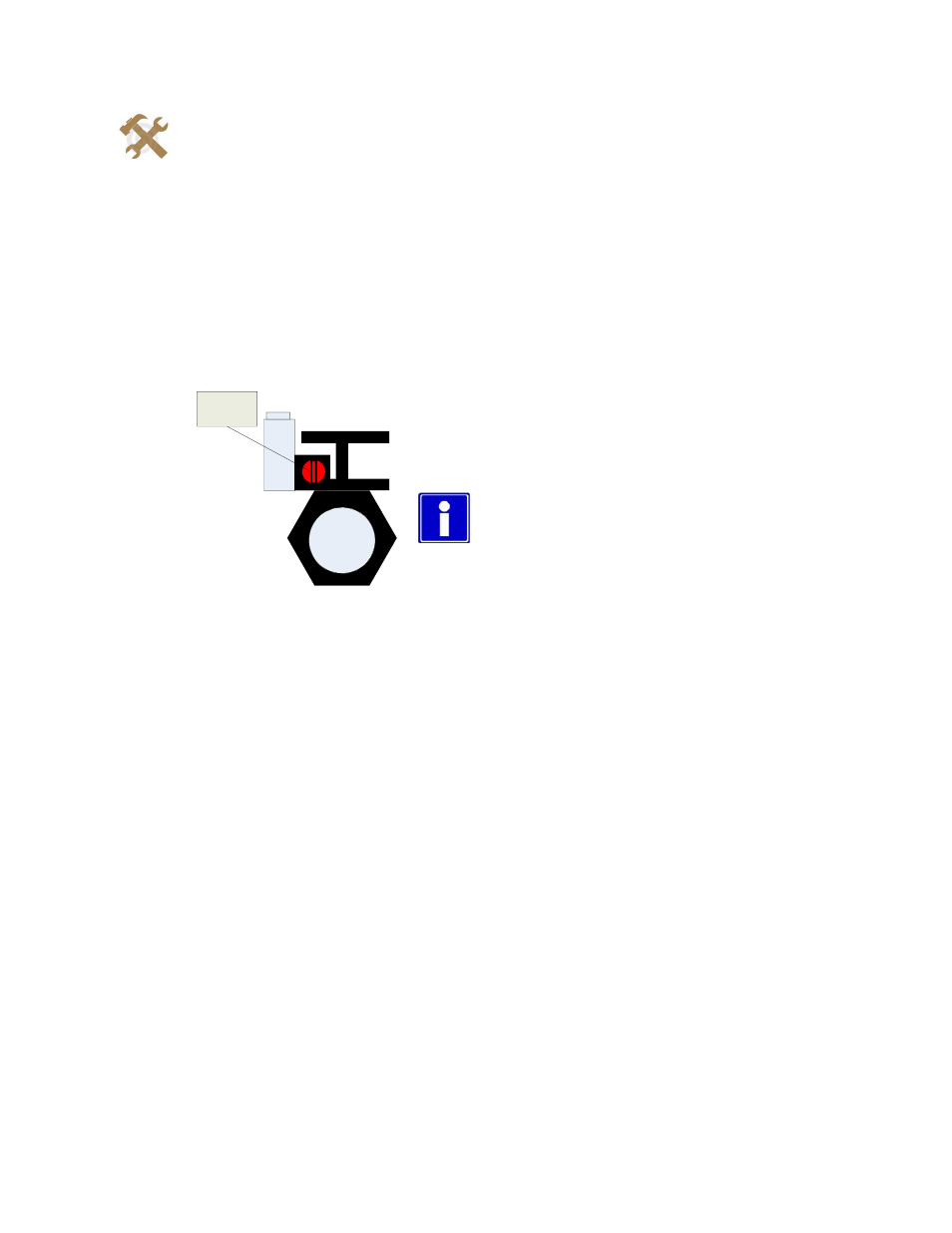

Valve

Closed

parallel (in-line) with its pipeline.

initial start-up. Additionally, the manual solenoid valve pilot switch

should be in the vertical position as shown to the left.

NOTE: The solenoid valve has a manual bypass switch

allowing the user to manually control water flow.

Ball valves have a “T” shaped handle that rotates a ¼ turn. Ball valves

are closed when the “T” handle is 90 degrees away (across) from its

associated pipeline. Ball valves are open when the “T” handle is

Globe valves have round hand wheels, and these are closed when the wheel is rotated fully clockwise

(viewed from top of wheel). Globe valves are opened by rotating the hand wheel counter-clockwise.

6.5.1.2 Valve Identification

System valves are:

1.1 Input

Water

Solenoid

Valve/Regulator

1.2

Primary Dilution Water – Globe

1.3

Secondary Dilution Water – Globe (note: not present in some configurations)

1.4 Mixing

Chamber

Drain

–

Ball

1.5

Neat Polymer Inlet – Ball

1.6

Neat Polymer suction side Drain – Ball

1.7

Neat Polymer suction side Bleed - Ball

1.8 Calibration

Column

Isolation

–

Ball

1.9

Neat Polymer discharge side Drain – Ball

1.10

Neat Polymer discharge side Bleed - Ball

1.11 Neat

Polymer

Isolation

–

Ball