Introduction, Principle of operation – Pulsafeeder Polyfeeder EN User Manual

Page 4

4

14.1

B-Series Polyfeeder Control Panel

l .................................................................................46

Introduction

The POLYFEEDER

©

is a reliable, efficient system for the make-down of polymer solutions.

Versions are available with a variety of neat polymer feed equipment to suit the individual

application, including solenoid, gear, and progressing cavity pump technology. Several control

options are available as well, to best integrate the system into the user’s facility.

2. Principle

of

Operation

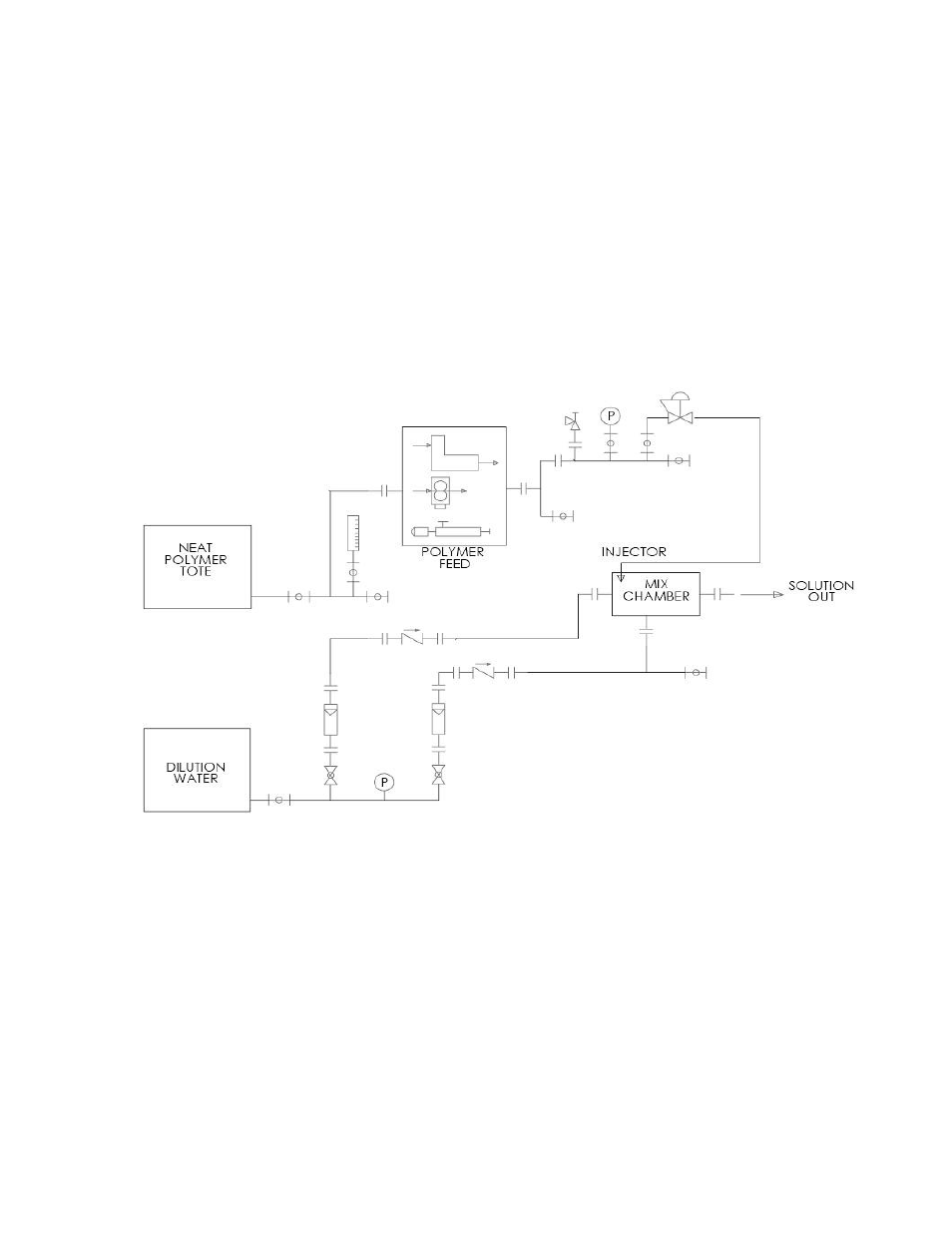

Figure 2-1 BASIC SYSTEM FLOW DIAGRAM

Dilution water is introduced to the system at the water inlet solenoid valve under pressure. T

he water is then delivered to the mixing chamber in one or two individual streams, primary

(required) and secondary (optional). The flow rate in each stream is regulated with a globe

valve and flowmeter.

The primary dilution stream is directed into the center of the mixing chamber, where it is

combined with neat polymer. Neat polymer is introduced to the system at the polymer inlet

valve and pumped via the polymer feed pump to an anti-clog polymer injector (patent

pending) located in the primary dilution water stream just prior to the mixing chamber. The

injector design prevents polymer from interacting with the water before it is injected.

The mixing chamber incorporates a motorized dispersion blade that, in combination with the

labyrinth design of the chamber itself, results in efficient and complete polymer make-down.

The neat polymer and water mixture is subjected to an initial high shear mixing zone and then

the mixing energy slowly diminishes until the solution exits the mixer.