2 control input requirements and wiring details – Pulsafeeder Polyfeeder EN User Manual

Page 17

17

6.6.2 Control Input Requirements and Wiring Details

6.6.2.1 Remote Start Input Contact Requirements

The Polyfeeder may be started remotely via a PLC/SCADA system or a remote located start/stop switch.

The user must provide a dry contact closure signaling the Polyfeeder to start (contact closed) or stop

(contact open). The contact or switch must be rated for 24 VDC and 1 amp.

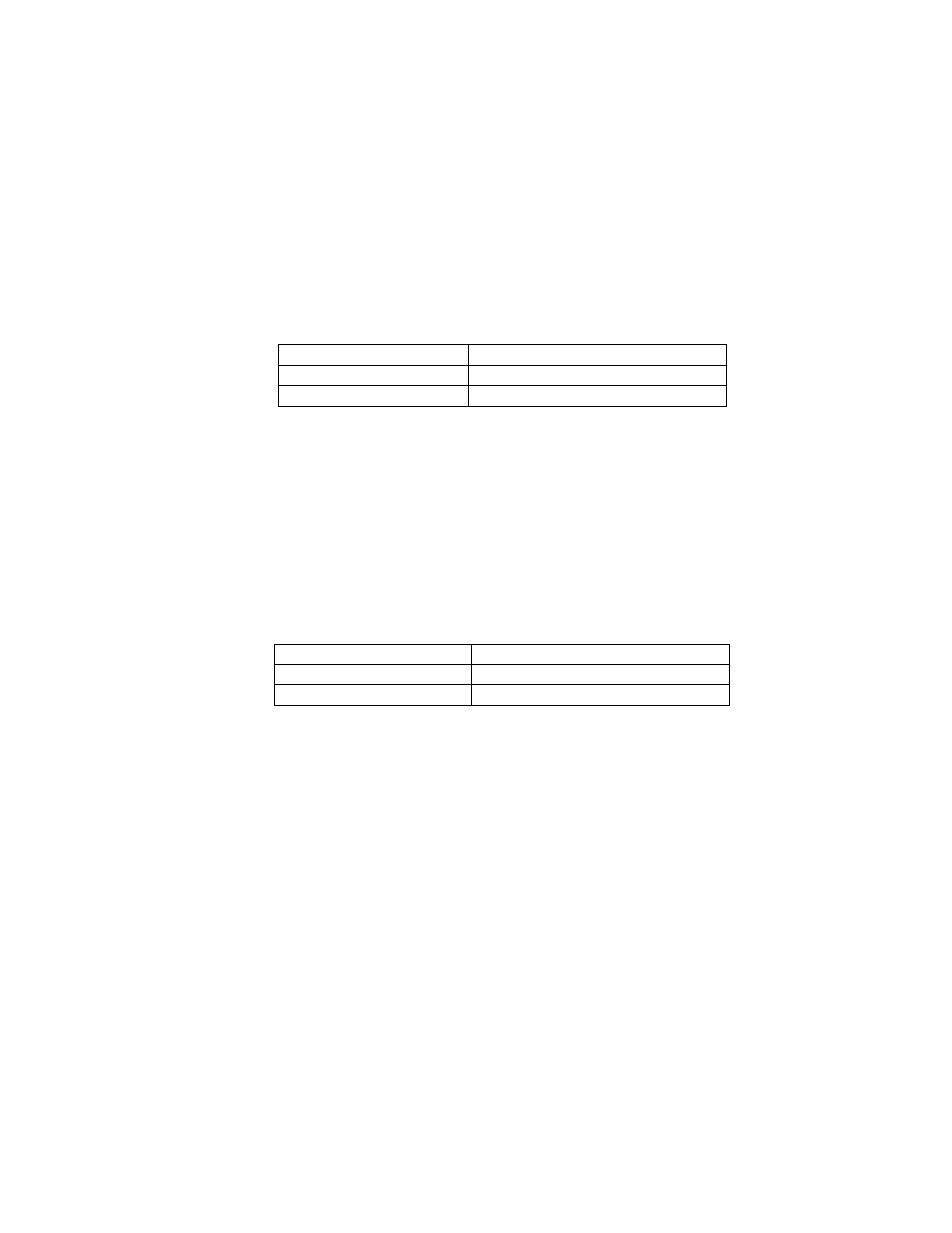

6.6.2.2 B-Series Remote Start Controller Wiring

Signal Terminal

Block

Location

Contact Side A

TB3-1300

Contac Side B

TB3-1790

Table 6-6-2-1 B-series controller Remote Start Contact Wiring

6.6.2.3 Remote Analog Input Requirements

The Polyfeeder B-series controller provides remote polymer concentration control via a two-wire analog

input. This analog input presents a 250 ohm impedance to the PLC/SCADA system. The PLC/SCADA

system must provide 4-20mA. Current sources must be sourcing capable externally loop powered

outputs. The analog control signal should be routed in a separate conduit and 20 AWG twisted pair

w/shield is recommended. The shield shall be tied to the customer PLC/SCADA system ground.

The wiring connection for this signal is listed below

Signal

Terminal Block Location

Positive TB3-3740W

Negative (Common)

TB3-1302

Table 6-6-2-3 Analog Polymer Demand input

6.6.2.4 Programmable Contact Output Requirements

The Polyfeeder B-series controller provides 3 programmable normally open dry contact output

connections capable of 5A @ 250VAC or 5A @ 30VDC. These outputs are programmable to allow the

user to signal the following system conditions:

1. SYSTEM RUNNING/STOPPED

2. LOCAL_REMOTE (Control Mode)

3. LOW POLYMER FLOW

4. LOW WATER FLOW

16 AWG wiring is recommended with 600 volt insulation rating.