Installing the unit (only for experts) – Karcher SB Wash Oel 50-10 F VA User Manual

Page 25

-

11

Notice

The equipment may only be installed by an

–

mechanic of Kärcher

–

or an from Kärcher authorized individu-

al

The following requirements are necessary

in order to install the equipment:

–

Horizontal, plane surface with firm base

admeasuring 845 x 725 mm next to the

SS wash.

–

Water connection with pipe separator

according to EN 1717m, for output data,

see "Technical Data". Follow national

regulations (DVGW in Germany).

–

By customer, lockable, access for the

wash customer emergency - off- main

switch.

–

Light at the washing area according to

the national requirements, in order to

assure safe working for the customer

when dark.

–

Power and water supply according to

the measuring sheet.

–

By operation in the winter, an isolated/

heated water supply sytem must be

guaranteed.

–

Drain water shaft and required drain

water disposal.

–

Drill fastening holes according to the

measurement sheet.

Unpack the equpiment and dispose of the

packing material properly.

Line up the equipment on the level ar-

ea.

Fix with the material included. Use the

inclosed spacer and set up the equip-

ment horizontal.

1 Dowel pin M10 (4x)

2 Unterlegplatte 5 mm (4x) Unterlegplatte

2 mm (4x)

3 Washer 10,5 (4x)

4 Hexagon screw M10 (4x)

Note

Impurities in the inlet water can damage the

unit. Kärcher recommends the use of a wa-

ter filter (see "accessories").

To ensure frost protection of the plant, the

water inlet must be protected against freez-

ing (through insulation and accompanying

heating).

ṇ

Warning

Risk of damage to the plant if water supply

is not of suitable quality. Use water only of

potable quality as water supply to the plant.

Quality requirements for tap water:

For connection values refer to technical

specifications.

Guide the inlet hose from the bottom

through the opening in the plant and

connect it to the base exchanger.

Install the solenoid valves, chemical

valve and the dosing valve in the SS

wash and connect them (see chart in

the chapter on Function).

Guide the cable of the ABS anti-frost

mechanism (hot air blower) through the

opening of the plant and connect it in

the electrical cabinet according to the

circuit plan.

Guide the enclosed cables through the

opening in the plant, secure them with

cable binders and connect them ac-

cording to the circuit plan.

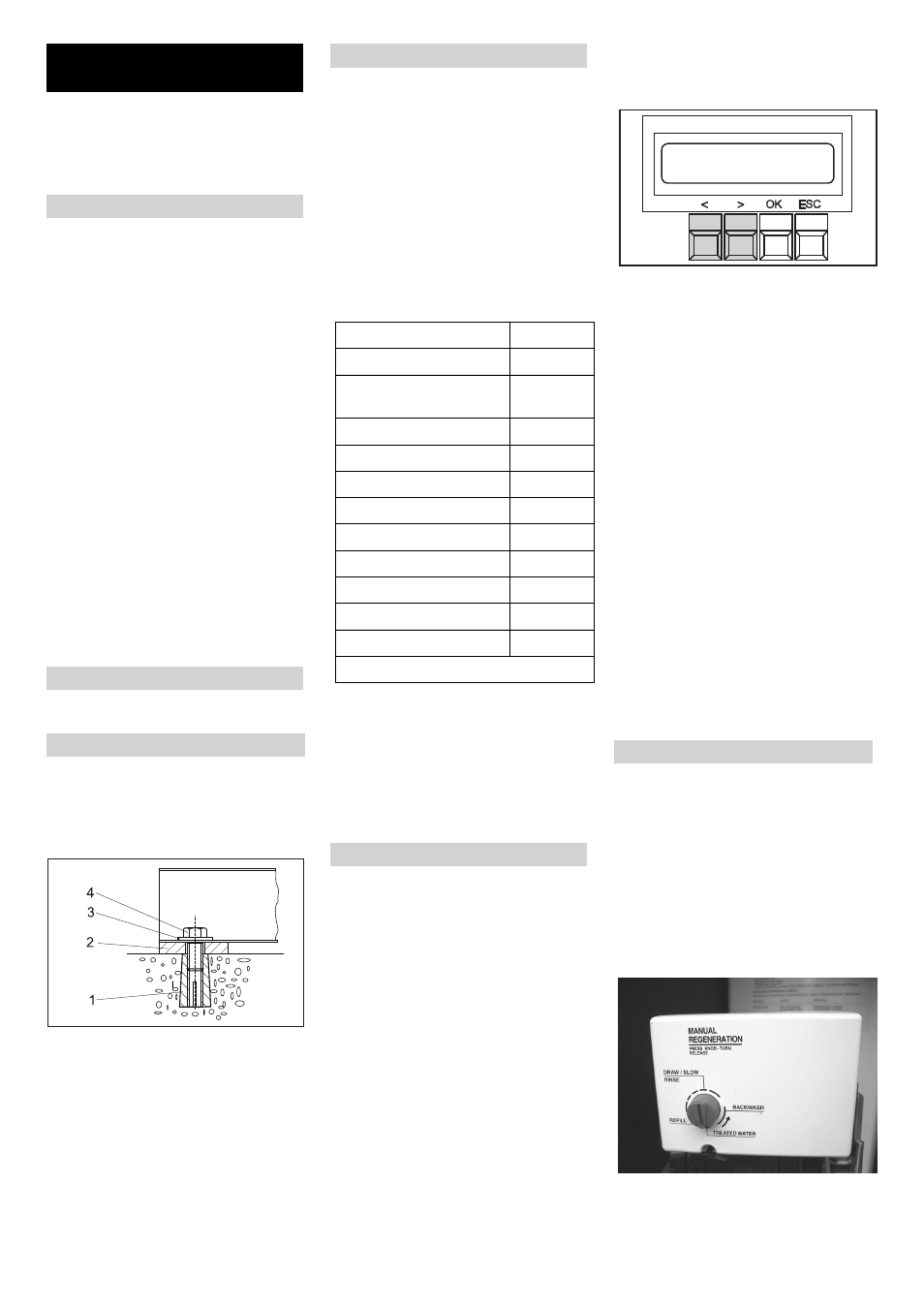

Carry out the following steps in the Control

menu for releasing the ABS osmosis:

Press "OK" button for 1 seconds

Display: Data Adjust

Press „<“ key

Display: Warm Water

Press „<“ key

Display: Options

Press "OK" key

Display: Half Load: OFF/ON

Press „<“ key

Display: Osmosis: OFF

Press "OK" key

Display: Osmosis: OFF blinking

Press „<“ key

Display: Osmosis: ON blinking

Press "OK" key

Display: Osmosis: ON glows continu-

ously

Press "ESC" key twice

Display: Save Parameter?

Press "OK" key

Display: DATA SAVING....

wait for approx. 5 seconds

Press "ESC" key

Settings completed

Inser the overflow hoses of base ex-

changer and salt tank in the drainage

pipe of the building.

Fill the salt tank with water (approx. 10

cm) Do not add any salt yet!

Open the locking valve in the inlet slow-

ly and wait until the pressure tank is

filled with water.

Remove the covering lid of the control

valve.

Press the programme button and select

the function "Backwash" by turning the

button in the direction of the arrow.

Installing the unit (only for

experts)

Preparing the installation place

Unpack the equipment

Aligning the unit and installing it

Water connection

Parameter

Value

pH value

6,5...9,5

electrical conductivity

max. 1000

μS/cm

Hydrocarbons

< 0.01 mg/l

Chloride

< 250 mg/l

Calcium

< 200 mg/l

Total hardness

< 28 °dH

Iron

< 0.2 mg/l

Manganese

< 0.05 mg/l

Copper

< 0.02 mg/l

Sulphate

< 240 mg/l

Active chloride

< 0.1 mg/l

free of bad odours

Electrical connection

Release ABS Osmosis

Turning the base exchanger on

Backwash

25

EN