Troubleshooting – Karcher SB Wash Oel 50-10 F VA User Manual

Page 23

-

9

ƽ

Danger!

There is danger of injury while working at

the equipment.. Concerning all works

disconnect the input water, close the

water supply,

disconnect the power supply, shut off

the customer emergency main switch,

and secure, that it can not be turned on.

–

Operator

Work designated with the sign “Opera-

tor” may only be carried out by persons

who have been instructed in the safe

operation and maintenance on the high

pressure plant.

–

Electricians

Persons with a professional training in

the electro-technical area.

–

Customer Service

Work designated with the sign “Cus-

tomer Service” may only be done by the

fitters of Kärcher Customer Service.

Troubleshooting

Who may remedy faults?

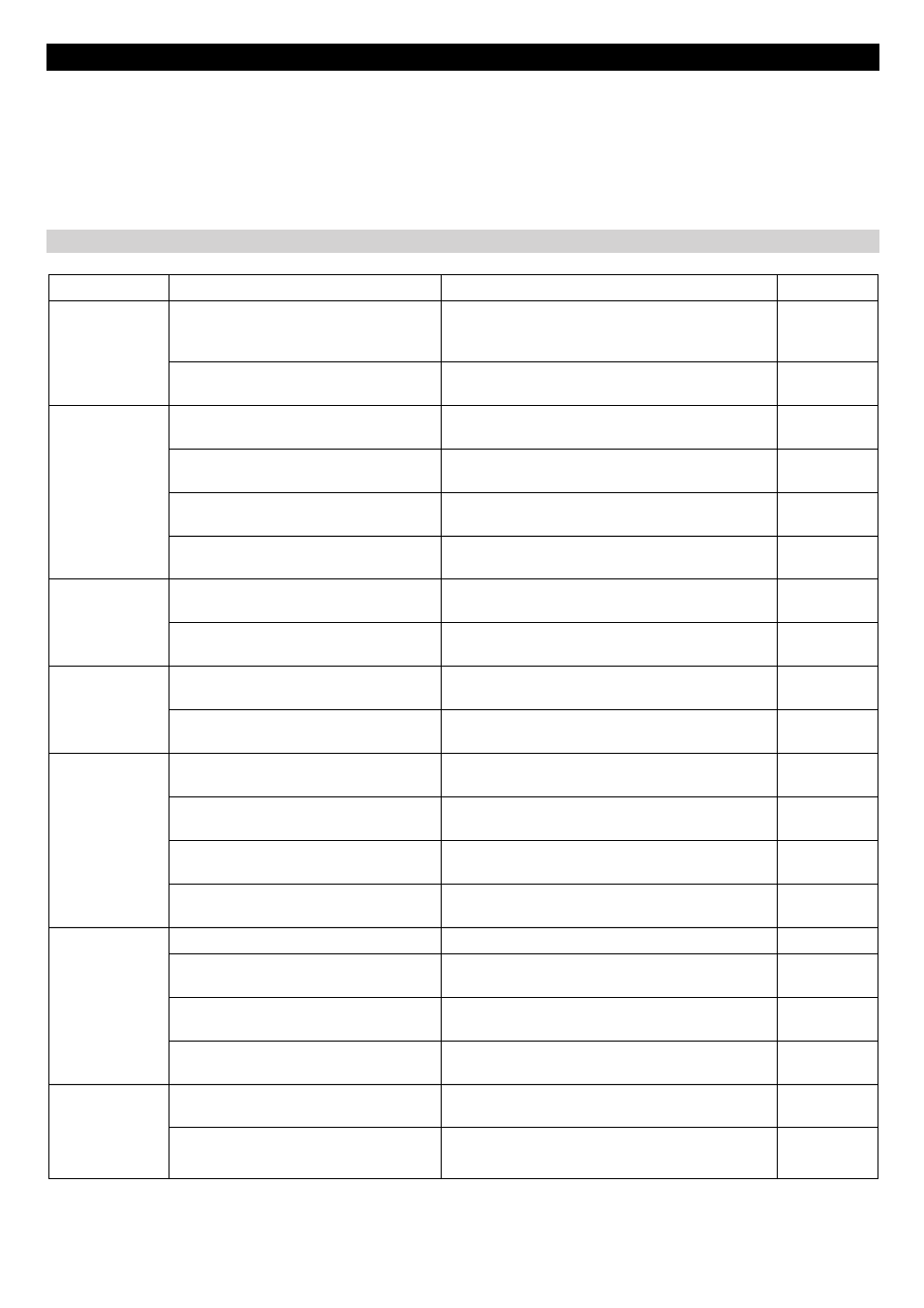

Faults

Fault

Possible cause

Remedy

By whom

Base exchanger

is not regenerat-

ing

No power supply

Check power supply (fuse, plug, switch).

Operator/

Customer

Service

Hardness sensor (....) defective

Check hardness sensor, replace if required

Customer

Service

Water remains

hard after regen-

eration

No salt in the salt tank

Fill up salt, do not allow the salt level to fall below the

water level.

Operator

Injector filter is blocked

Clean the filter

Customer

Service

Water flow to the salt tank is inadequate

Check the brine filling duration; clean the brine filling

aperture, if required.

Customer

Service

Rising pipe is leaky

Check rising pipe, pilot pipe

Customer

Service

too high salt con-

sumption

too much water in the water tank

see below

Customer

Service

wrong salt quantity setting

Check salt consumption and salt settings

Customer

Service

Pressure loss

Deposits in water inlet

Clean the filter

Customer

Service

Deposits in base exchanger

Clean valve and resin board

Customer

Service

Too much water

in the salt tank

Rinsing aperture is blocked

Clean rinsing aperture

Customer

Service

Injector is blocked

Clean injector and filter

Customer

Service

Foreign particles in the solenoid valve

Clean the solenoid valve, change the valve seat

Customer

Service

Power failure while filling brine

Check power source

Customer

Service

Brine is not get-

ting sucked in

Water inlet pressure is too low

Increase water pressure to at least 0.3 MPa (3 bar). Operator

Rinsing aperture is blocked

Clean rinsing aperture

Customer

Service

Injector is blocked

Clean injector and filter

Customer

Service

Leak inside the valve

Replace valve flaps

Customer

Service

There is always

water in the

drainage, even

after regenera-

tion

Valve does not execute the correct cycles Check timer programme; replace the valve controls,

if required

Customer

Service

Foreign particle in the valve

Remove the valve control, take out the foreign parti-

cle, check valve in all the positions

Customer

Service

23

EN