Maintenance and care – Karcher SB Wash Oel 50-10 F VA User Manual

Page 22

-

8

The bases of a safe operating of the equip-

ment is thr regularly maintenance accord-

ing to the following maintenance plan.

Use exclusively original parts of the manu-

facturer or those parts recommended by

him like

–

parts and wearing parts,

–

accessories parts,

–

operating materials,

–

cleaning agents.

ƽ

Danger!

There is danger of injury while working at

the equipment.. Concerning all works

disconnect the input water, close the

water supply,

disconnect the power supply, shut off

the customer emergency main switch,

and secure, that it can not be turned on.

–

operator

Performances containing the notice

"operator" may only be performed by in-

structed individualls, who are able to

operate and service high pressure

equipment.

–

Maintenance

Performances with the notice "mainte-

nance" may only be performed by the

Kärcher- Maintenance-Mechanics.

In order to guarantee a reliable operation

og the equipment, we success, you signed

a maintenance agreement. Please refer to

you local Kärcher service department.

Maintenance and care

Maintenance instructions

Who may perform maintenance?

Maintenance contract

Maintenance schedule

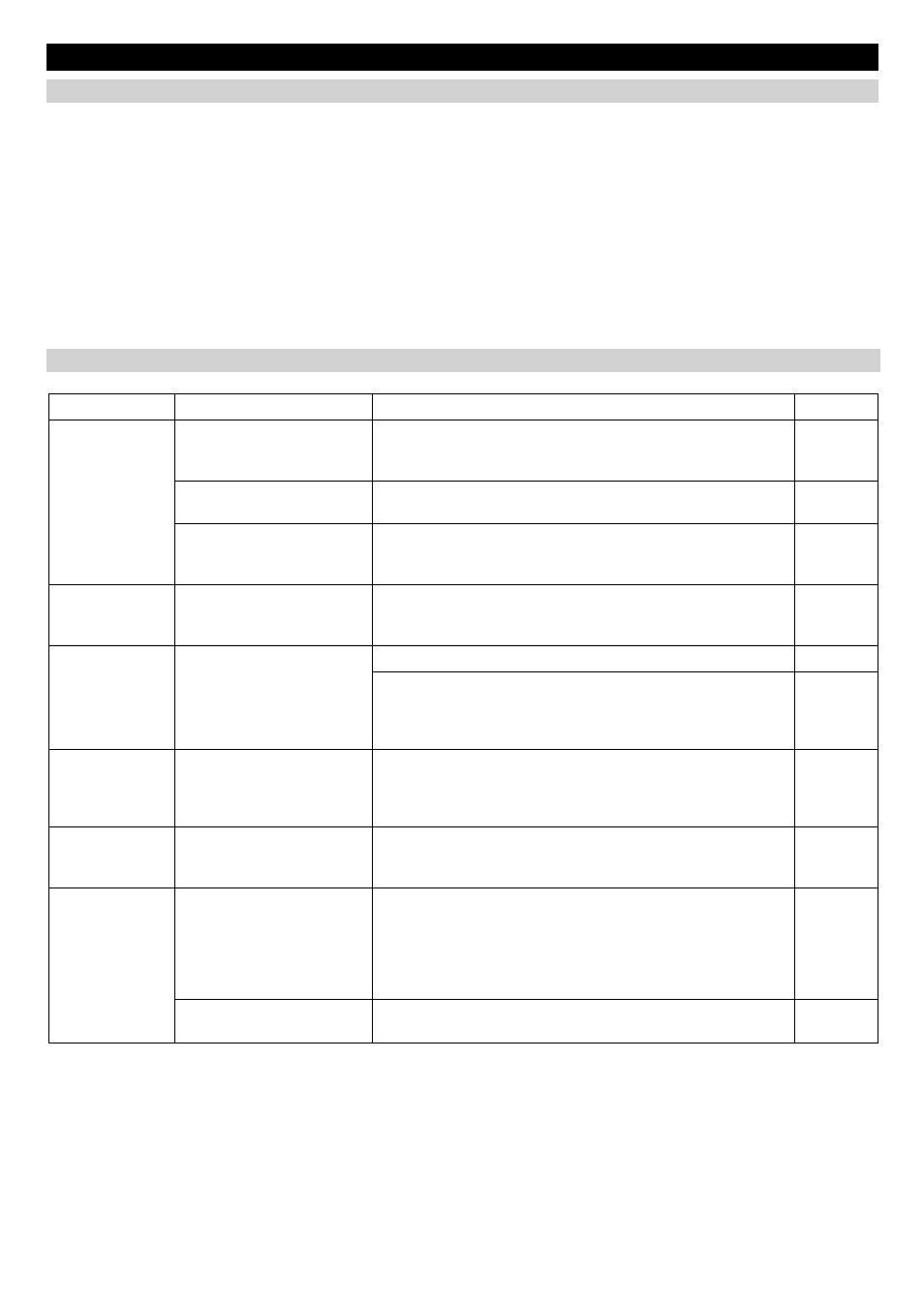

Time

Activity

Performance

of whom

Weekly or after 40

operating hours

Check tightness

Check pumps, fixtures and pipe systems for leaks.

Operator/

Customer

Service

Check salt stock in the salt

tank

Is the salt level above the water level? If required, top up softening

salts.

Operator

Check residual hardness of

softened water

Take water from the swimmer tank for fresh water (SS wash) and

determine its residual hardness using test set B (order no. 6.768-

003) Target value: below 3 °dH

Operator

Once, 1 month af-

ter start-up

Replace finest filter

Close the locking valve for fresh water (building site), unscrew the

filter cup, replace the filter inlay, insert the new filter inlay and the

filter cup back into place, open locking valve for fresh water.

Operator

After 160 operat-

ing hours or once

a month

Check salt tank

Check water level (approx. 5 ... 25 cm above the sieve plate).

Operator

Check for deposits; if required, empty the tank, clean it, fill it up with

softening salts and start it up again. Risk of functional disturbances.

While filling the softening salts, use only the softening salt in the

tablet form listed in the chapter "Accessories".

Operator

Depending on the

chlorine content of

the fresh water

Check active carbon filter

Take water sample at the rinsing valve of the active carbon filter.

Check using test set 6.803-028.0. If chlorine content exceeds 0.1

mg/kg chlorine, replace the filter inlay (once a year, see mainte-

nance plan).

Operator/

Customer

Service

Half-yearly or after

1000 operating

hours

Replace finest filter

Replace filter inlay; do not clean it.

Operator

annual

Change filter inlay of active

carbon filter

Close the locking valve for fresh water (building side), unscrew the

filter cup and rinse it, replace the filter inlay through a new filter in-

lay, reinstall filter inlay and filter cup, open the locking valve for fresh

water, slowly open the rinsing valve for active carbon filter and rinse

the active carbon filter for 1 minute, close the rinsing valve for active

carbon filter and start the plant.

Operator/

Customer

Service

Check pump

Inform Customer Service. Check characteristic line (flow quantity

and pressure).

Customer

Service

22

EN