Brief instructions for maintenance and servicing, 43 en, Menue navigation – Karcher SB-WASH 50-10 User Manual

Page 43

-

20

Brief instruction SB-WASH

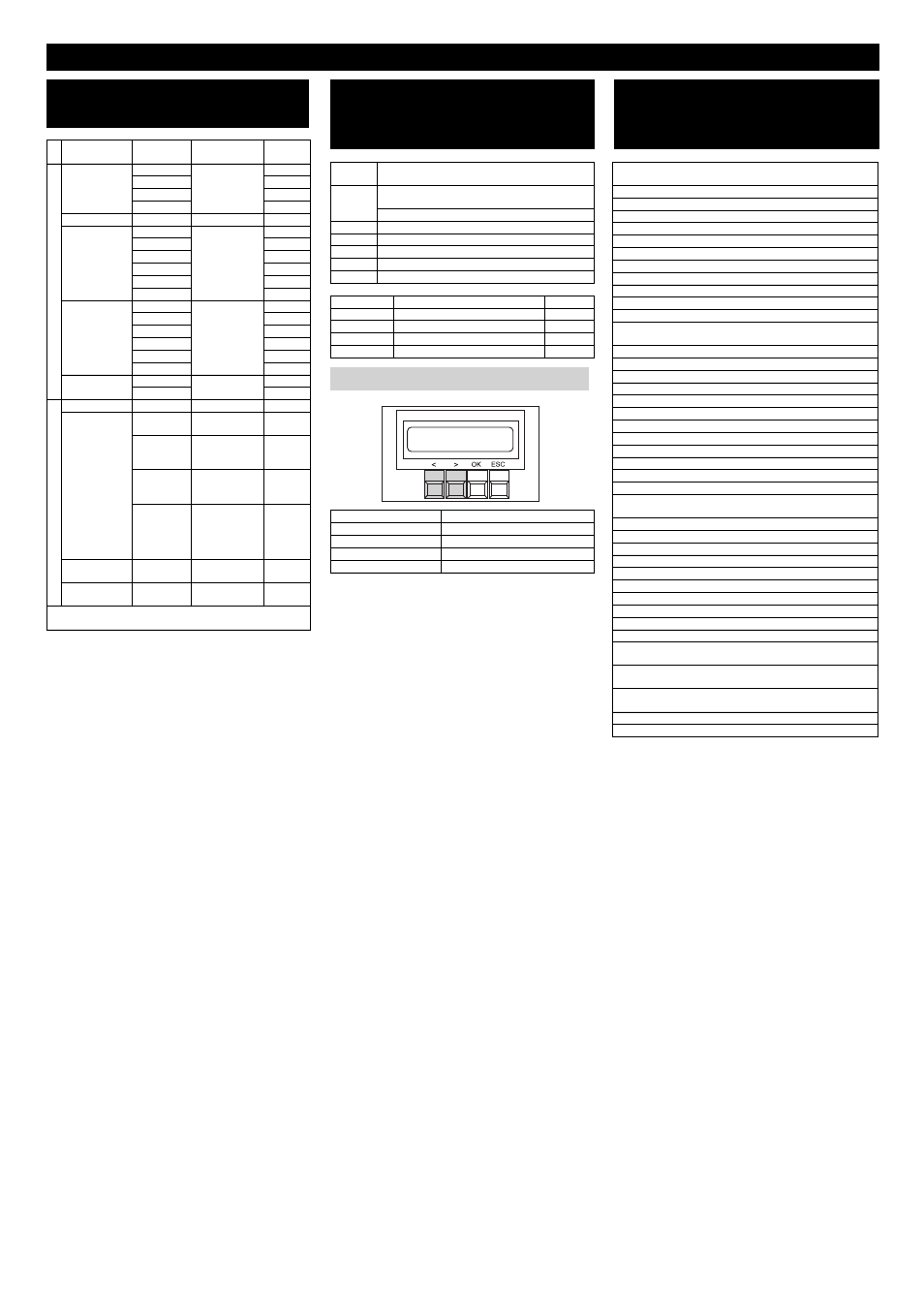

Adjustment control circuit

board

Menue point

adjustment Option

Standard

setting

Adjust

Warm-Water

Progr. 1

warm/ cold

warm

Progr. 2

cold

Progr. 3

warm

Progr. 4

cold

Time-Base

Time-Base:

30...300 s

90 s

Wash-Time

Progr. 0

100...50%

100%

Progr. 1

60%

Progr. 2

90%

Progr. 3

70%

Progr. 4

60%

Progr. 5

60%

Coin-Amount

Channel 1:

10...200

10

Channel 2:

20

Channel 3:

40

Channel 4:

10

Channel 5:

20

Channel 6:

40

Options

Halfload

On/Off

Off

Osmosis

Off

Data

Version

Version: x.x

Statistics

Coin

Counter

Today: Coins

Total: Coins

*)

Timer

HP-Pump

Total: hours

S001: hours

S002: hours

Timer Burner Total: hours

S010: hours

S020: hours

Timer-Pro-

grams

Progr 1: hours

Progr.2: hours

Progr.3: hours

Progr.4: hours

Progr.5: hours

Error

Message

Error: Exxx

Service

Service:

Sxxx

*) Reset coin sum- daily counter: Push the "<" and ">" for two

seconds at the same time.

Interruptions and service

announcements control

circuit board

Error

codes

Cause

E001

Motor protection switch -Q1 or development temper-

ature switch of the HD-Pumpe has triggered off

Winding protection contact motor

E002

Fuse - F1 has triggered, circulating pump, heat fan

E003

Interruption warm water heater

E004

Osmosewater is empty (Option)

E005

Cleaning agent container/fluel empty /Option)

E100

Interruption control circuit

Servicecode Meaning

Intervall

S001

pump head HD-pump

250 h

S002

HD-Pump totally

500 h

S010

Burner lid ( starter)

250 h

S020

fuel valve, burners are blacking

500 h

Menue navigation

Button

Action

OK, for 2 seconds

open the menue

<, >

change values, turn menue

OK

Confirm

ESC

cancel, exit

Brief Instructions

for maintenance and

servicing

Please pay attention to the section "maintenance and serv-

ice" in the operation instructions!

DAILY

Checl high pressure hose

check brush

Check information notices in the equipment

Check the pipe line and high pressure pump for tightness

Check the content of the cleaning agent container

Check the content of the fuel container

DAILY IF FROST

Check and if needed clean the fan heater and the anti freeze cycle

After 40 operating hours, or weekly

Check oil level of the high pressure pump

Check the oil condition of the high pressure pump (is there water

in the oil?)

Clean the brush shaft and the floaing container

EVERY 14 DAYS

Clean and service the housing of the total equipment

After 160 operating hours, or monthly

Clean the coin mechanism.

Clean the filter of the cleaning agent container

Grease the joints at the doors

AFTER 250 OPERATING HOURS OR SEMI-ANNUALLY

Check pump head (Customer Service)

Adjust ignition electrode, replace if required (customer service)

BEFORE THE FROST PERIOD

Check the anti freeze equipment of its function

BEFORE THE FROST PERIOD AND DURING THE FROST

PERIOD MONTHLY

Check the freezing water amount

After 500 operating hours, or yearly

Change the oil and high pressure pump

Clean the soot of the heating coils and decalcify (Maintenance)

Adjust burner (Customer Service)

Clean the fuel container

base exchanger (optional)

Pay attention to the saltusage, check daily

Refill the salt, if the water level is above the salt

Check salt container, remove sludge

The suction jet of the salt container must be put to the grounf of

the container

The gree light at the E-equipmentboard is blinking => base ex-

changer does regenerate

PROPORTION EQUIPENT HAS TO BE DECALCIFIED RM

110 (OPTION)

Pay attenetion to the amount used of the RM110, check daily

Red light at the E-equipment board => container empty

43

EN