35 en, Maintenance schedule – Karcher SB-WASH 50-10 User Manual

Page 35

-

12

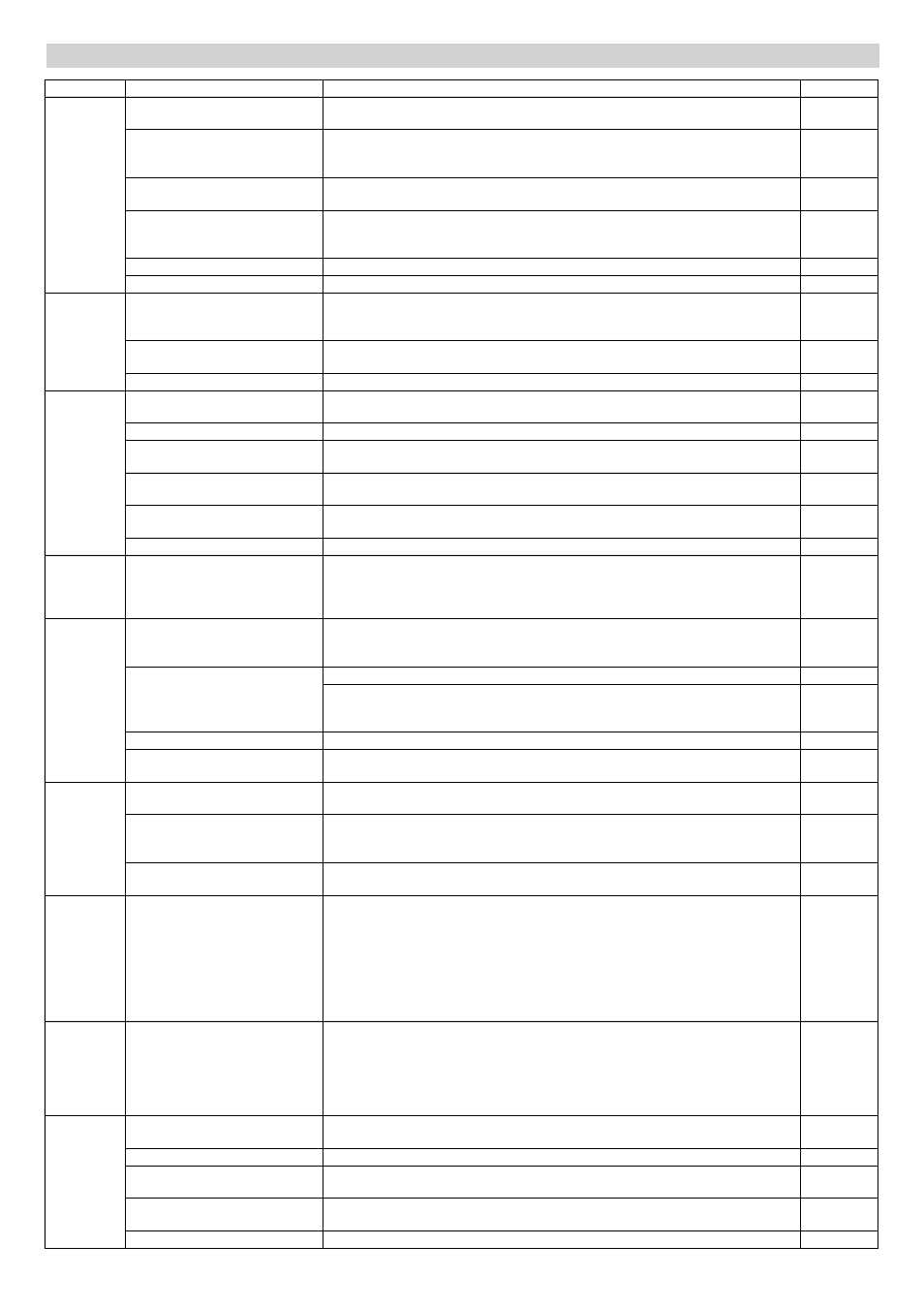

Maintenance schedule

Time

Activity

Performance

By whom

Daily

Visible inspection of the high pres-

sure hoses

Check high pressure hoses for mechanical damages such as scraping, visible hose

duck, bends, porous and cracked rubber. Replace damaged high pressure hoses.

Operator

check brush

concerning dirt, damage and waerout. If the bristles are shorter than 30mm, change

them. In the winter time, if it is –5 °C check several times a day besause of ice lock the

foam washing. Exchange the combi. steel pipe with the high pressure-steel pipe.

Operator

Check warning boards at the wash-

ing place

Check whether the warning boards for the users are available and legible.

Operator

Check the unit for leaks

Check pumps and pipes for leaks. Inform Customer Service if there is oil under the high

pressure pump, if more than 3 drops of water drop out of the high pressure pump when

the pump is running.

Operator

Check filling level of the detergent. Check filling level, refill if necessary.

Operator

Check fill level of fuel tank

Check filling level, refill if necessary.

Operator

Everyday un-

der frost con-

ditions

Check frost protection devices

Is the hot air ventilator working? Is the anti freeze cycle functioning (anti freeze water

amount approximately 0,5 l/min)? Is the drain of the brush shaft to the swimming con-

tainer free of ice?

Operator

Cleaning the sieve

Open the screw ( one top of the high-pressure pump), take out the strainer and clean

it, put the strainer back in, close the screws tight.

Operator

Clean the filter of the anti freeze pump. Clean the filter and replace

Operator

After 40 oper-

ating hours or

once a week

Check oil level of the high pressure

pump

The oil level must lie between the MIN and MAX markings; else refill.

Operator

Check oil level

Milky oil indicates that it contains water. Inform Customer Service.

Operator

Check the salt reserve in the salt

container (optional)

Is the salt level above the water level? If required, top up softening salts.

Operator

Check the level of the water soften-

er (optional)

Check filling level; refill the softener RM 110, if required.

Operator

Hardness of the water check ( by

bse exchanger option)

Take water from the fresh water container, and check the hardness by using the inspec-

tion set B ( ording number: 6.768-003) . Target value: below 3 °dH

Operator

Clean the brush shaft

Remove the dirt from the brush shaft.

Operator

After 80 oper-

ating hours or

once every

two weeks

Clean and maintain housing

Clean the housing thoroughly from inside and outside. After cleaning conserve it with

high grade steel agent (ordering number: 6.290-911).

Operator

After 160 op-

erating hours

or once a

month

Clean the filter of the cleaning

agent by using the cleaning agent

cotainer.

Remove filter and rinse it thoroughly with hot water.

Operator

Check the salt container ( by base

exchanger optional)

Check water level (approx. 5 ... 25 cm above the sieve plate).

Operator

Check for deposits; if required, empty the tank, clean it, fill it up with softening salts and

start it up again. Risk of functional disturbances. While filling the softening salts, use

only the softening salt in the tablet form listed in the chapter "Accessories".

Operator

Lubricate the door hinges

Lubricate the hinges with grease (order no.: 6.288-072).

Operator

Oil the locks, doors , the control cir-

cuit doors, and the coin container.

Spray care liquid (order no. 6.288-116) into the locks.

Operator

After 250 op-

erating hours

or once every

six months

Check pump head

Customer

Service

Check the pump hose in the dosing

pumps

Check the pump hose for cracks and wear; replace if required.

Operator/

Customer

Service

Adjust ignition electrodes, replace

if required.

Customer

Service

before the

frosting period

Check frost protection devices

Change the freezing thermostat in the direction of "check", until the anti freeze equip-

ment is turned on. Fan heater and freezing cycle must start. If the temperature is above

5 °C in addition, turn the thermostat of the fan heater up. Then turn the frost protection

thermostat in an anti-clockwise direction until the stop. Reset the thermostat of the hot

air blower.

Note

The openings in the equipment socket may not be closed, otherwise the function of the

anti freeze thermostat is interrupted.

Operator

Before the

frosting period

and on month-

ly basis during

the frosting pe-

riod.

check the anti freeze water amount

at the anti freeze cycle

Target value: approx. 0.5 l/min

Water quantity is higher: Change the node piece in the hand-spray gun.

Water quantity is lesser Clean filter for frost protection pump; clean sieve in throttle,

clean pipes, check the rotation direction of the pump.

Operator

After 500 op-

erating hours

or once a

year

Check the high pressure pump

thoroughly

Customer

Service

Oil change in high pressure pump See Maintenance tasks

Operator

Desoot the heating coil, adjust

burner

Customer

Service

Decalcify the heating coil

See Maintenance tasks

Trained op-

erator

Clean the fuel container

See Maintenance tasks

Operator

35

EN