Water-block orientation, Water-block installation, Retention frame issues – Swiftech H20 120 R3A User Manual

Page 32: Attaching the tubes, Type of coolant, Final inspection

Copyright Swiftech 2004 – All rights reserved – Last revision date: 11-23-04

Rouchon Industries, Inc., dba Swiftech – 1703 E. 28

th

Street, Signal Hill, CA 90755 – Tel. 562-595-8009 – Fax 562-595-8769 - E Mail:

[email protected] – URL:

http://www.swiftnets.com

- Information subject to change without notice Page 32 of 38

Lightly coat the CPU with the included Arctic Céramique thermal compound. Application will vary depending on the type of

processor. We recommend visiting http://www.arcticsilver.com for detailed instructions.

2. W

ATER

-

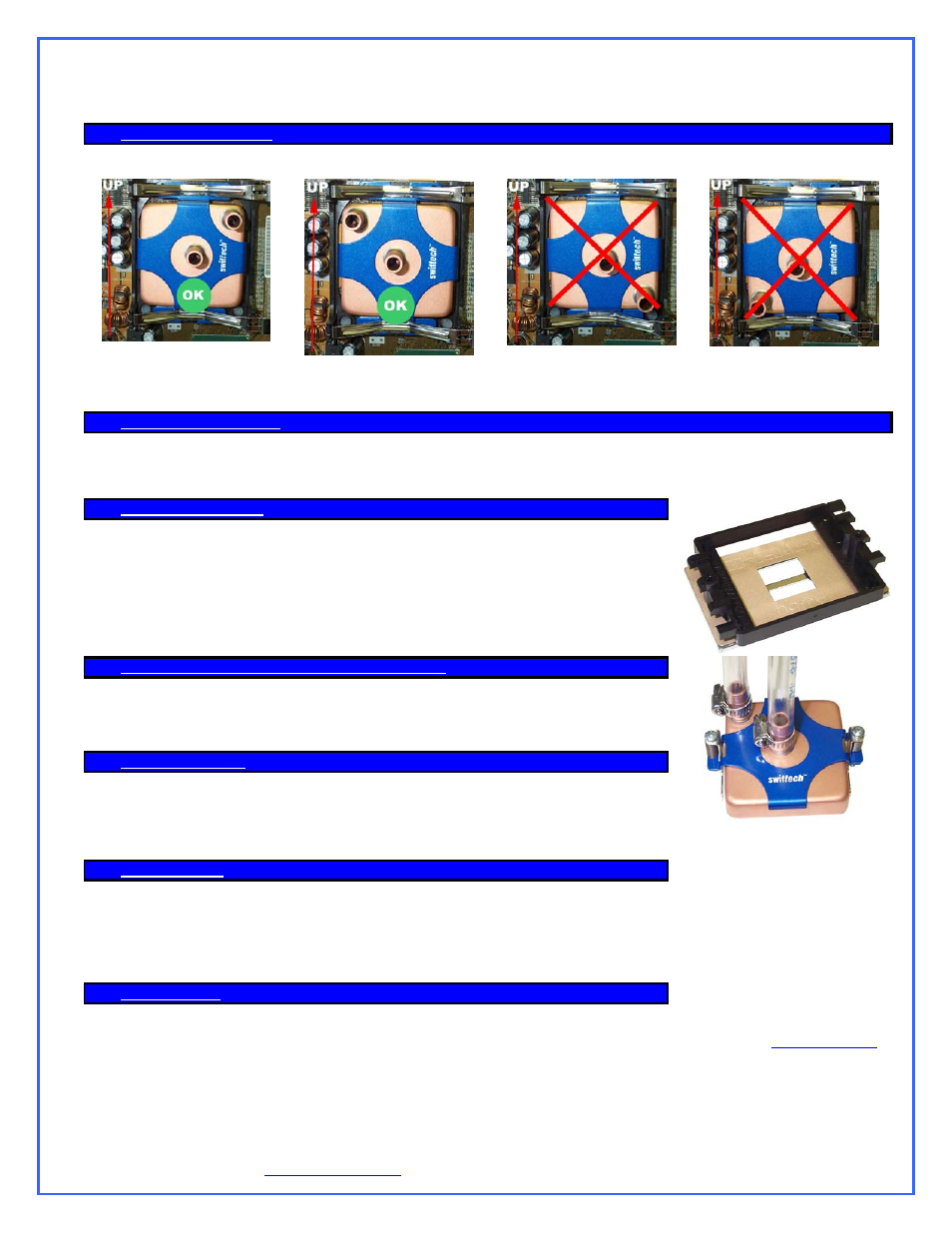

BLOCK ORIENTATION

For ease of operations during bleeding, the outlet should always be at the highest point (while system is standing upright)

3. W

ATER

-

BLOCK INSTALLATION

:

The MCW6000™ simply bolts onto AMD retention frame as shown in figure 1, using the enclosed spring-loaded screws. The tension limiter is

designed to provide appropriate tension to the springs. Do not over-tighten the springs.

4. R

ETENTION FRAME ISSUES

:

Most K8 compatible motherboards are shipped with AMD’s validated plastic retention frame and

metallic back-plate. In an effort to spare unnecessary costs to the majority of users, Swiftech does not

include these items with the MCW6000 water-block.

Some motherboards however use non-standard retention systems, and plastic back-plates instead of

the recommended metallic plates described in AMD’s Athlon™ 64 Processor Thermal Design Guide.

For this reason, Swiftech offers an optional retention frame and back plate made to AMD

standards, under Part # AJ00172 shown to the right.

Tubes attached with worm-drive

clamps

5. C

ONNECTING THE WATER

-

BLOCK

(

S

)

TO THE COOLING CIRCUIT

:

Carefully identify the direction of the flow in your circuit. For the MCW6000 to operate properly, the

fitting located at the center of the water-block MUST BE USED AS THE INLET.

6. A

TTACHING THE TUBES

:

In kit form, the MCW6000™ ships with 2’ of tube already clamped to inlet and outlet. When sold

separately, two worm-drive hose clamps are included.

7. T

YPE OF

C

OOLANT

:

Being entirely made of copper, the MCW6000™ may be used with pure water, and does not

necessitate the use of anti-corrosion agents. The use of an algaecide is nonetheless recommended in

any liquid cooling system, and our HydrX™ additive also performs such function.

8. F

INAL INSPECTION

:

Once the installation is completed, it is always a good idea to test the circuit for leaks, prior to powering

up the computer. Do not test the water-block using city water pressure. This will bow the top of the

housing and render the block unusable (and will void your warranty). Maximum pressure allowable

for testing is 25 psi (1.7 bar)

Troubleshooting help is available on

our w

,

or by calling customer support at

562-595-12009.