Type of coolant, Final inspection – Swiftech H20 120 R3A User Manual

Page 30

Copyright Swiftech 2004 – All rights reserved – Last revision date: 11-23-04

Rouchon Industries, Inc., dba Swiftech – 1703 E. 28

th

Street, Signal Hill, CA 90755 – Tel. 562-595-8009 – Fax 562-595-8769 - E Mail:

[email protected] – URL:

http://www.swiftnets.com

Place the MCW6000-A

over the CPU as shown in figure 1 page 1.

The water-block step side MUST be located over the socket cam box. A label affixed to the base

of the water-block clearly identifies which side this is.

The retention clips should snap over each side, and hook onto the socket tabs. Make sure

that the clips are properly aligned to fit snugly underneath the tabs.

Gradually

loosen (counter-clockwise) each spring-loaded screw to release the spring

tension, checking that the clips remain engaged underneath the tabs.

TIP: if space permits, hold the clips pressed against the socket while loosening the screws,

as shown in figure 2. This will prevent the clips for disengaging themselves from underneath

the tabs at start-up.

Figure 2

Continue backing off until the head of the screw completely clears the top of the

bracket, as shown figure 3.

Double-check

to ensure that the clips have remained underneath the tabs.

Installation on the CPU is now complete!

Figure 3

- Information subject to change without notice Page 30 of 38

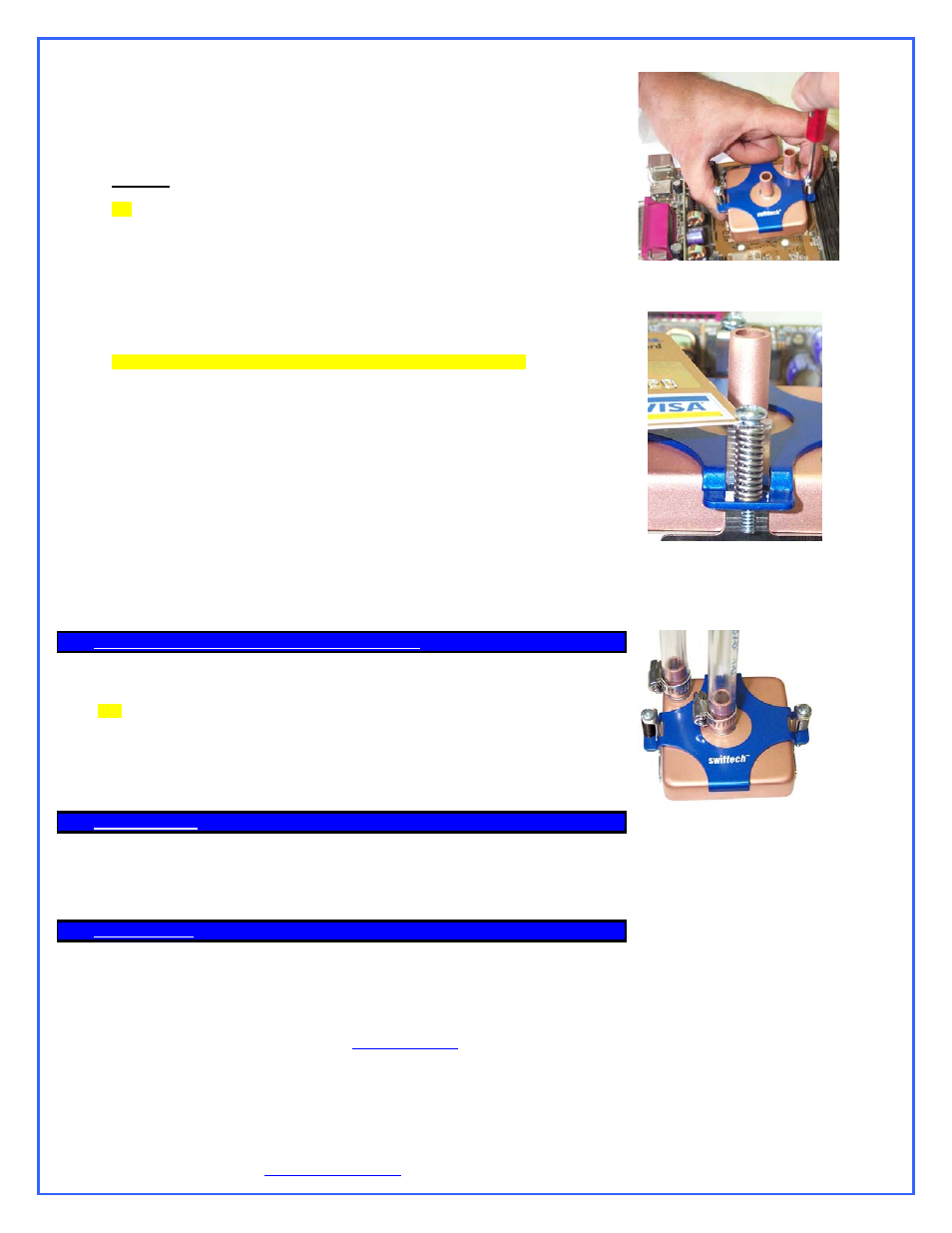

Tubes attached with worm-

drive clamps

4. C

ONNECTING THE WATER

-

BLOCK

(

S

)

TO THE COOLING CIRCUIT

:

Carefully identify the direction of the flow in your circuit. For the MCW6000 to operate properly,

the fitting located at the center of the water-block MUST BE USED AS THE INLET.

TIP!

In multi-processor environments, connect the two blocks in series: For example: pump

discharge to inlet of processor 1, discharge of processor 1 to inlet of processor 2, and

discharge of processor 2 to radiator.

Attaching the tubes:

In kit form, the MCW6000™ ships with 2’ of tube already clamped to inlet and outlet. When

sold separately, two worm-drive hose clamps are included.

5. T

YPE OF

C

OOLANT

:

Being entirely made of copper, the MCW6000™ may be used with pure water, and does not

necessitate the use of anti-corrosion agents. The use of an algaecide is nonetheless recommended

in any liquid cooling system, and our HydrX™ additive also performs such function.

6. F

INAL INSPECTION

:

Once the installation is completed, it is always a good idea to test the circuit for leaks, prior to

powering up the computer. Do not test the water-block using city water pressure. This will bow

the top of the housing and render the block unusable (and will void your warranty). Maximum

pressure allowable for testing is 25 psi (1.7 bar)

Troubleshooting help is available on our

, or by calling customer

support at 562-595-12009.