Swiftech SLI/Crossfire bridges for MCW60/80/82 User Manual

Sli/crossfire bridge series

Copyright Swiftech 2011

– All rights reserved – Last revision date: 9-9-11 – Rouchon Industries, Inc., dba Swiftech® –151 West Victoria St., Long Beach, CA 90805 – Tel.

(310) 763-0336 - Toll free (US) 888-857-9438

– Fax (310) 763-7095 - E Mail: [email protected] – URL: www.swiftech.com - Information subject to change without notice

SLI/CrossFire Bridge series

INSTALLATION GUIDE

Compatible fittings general specifications

Thread Size and class

Thread length

O-ring style

Fitting Style

¼” BSPP, G1/4”

Up to 5mm

Built-in (

“Eurostyle”)

All barb fittings, All Compression up to ½” tube OD

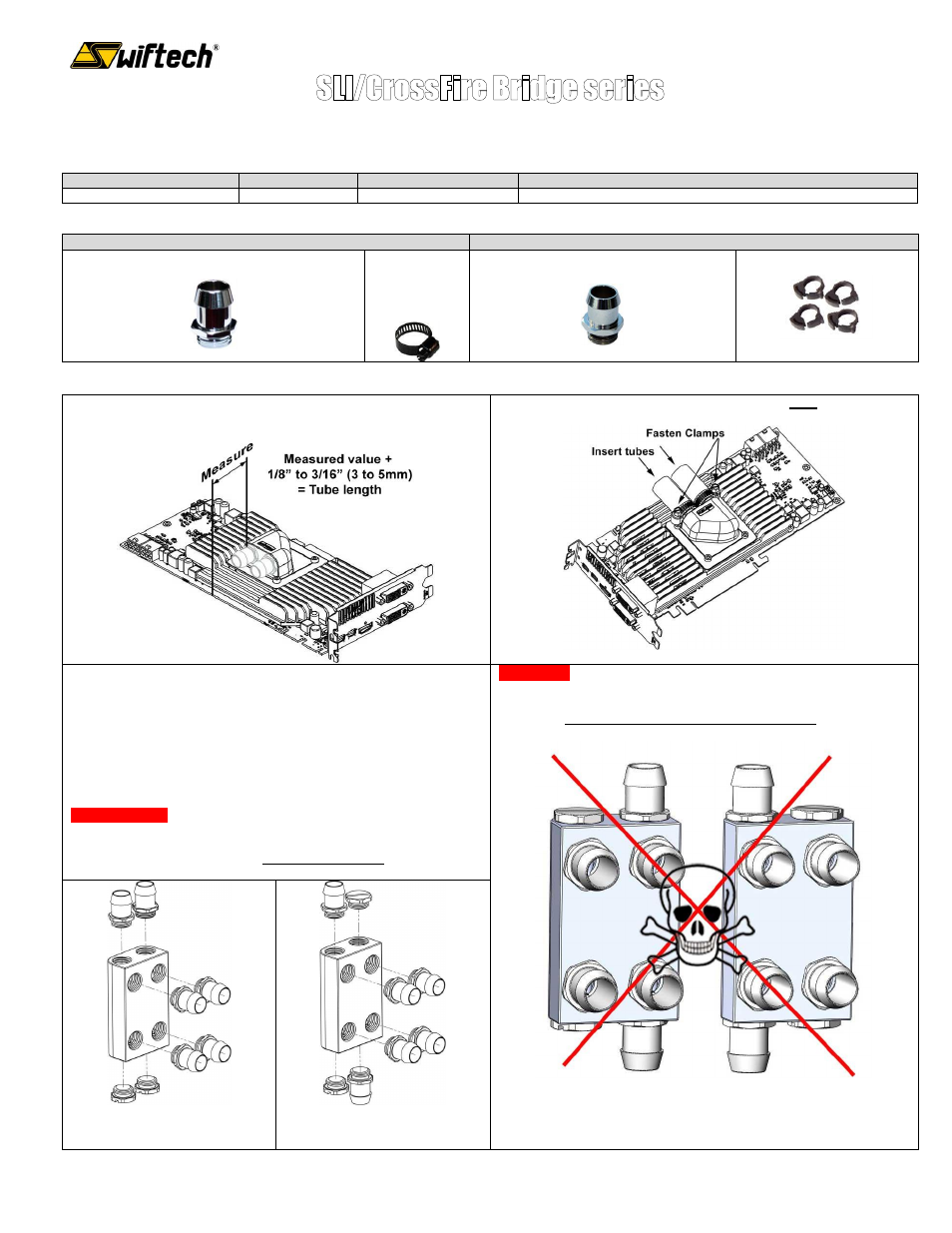

Compatible Swiftech fittings & clamps

For ½” ID (5/8” or 3/4” OD) tubing

For 3/8” ID (1/2” OD) tubing

Use with

Worm-drive

clamp

(set of 4)

Use wit

Step 1: Cut the tubing to length

– Make sure all tubes are of equal

length!

Step 2: Insert the tubes and fasten the clamps to each waterblock

Step 3: Install the fittings to the bridge

Installation of the upper and lower fittings will depend on how your loop is

routed. Two typical examples are shown below.

Fasten the fittings until they completely mate with the bridge: the metal

flange of the fitting must sit flat against the surface of the bridge, thus

compressing the O-ring, and then tighten them

using a 5/8” (15mm)

wrench or socket as described below.

CRITICAL READ: The tightening force (torque) must be firm but not

excessive: not enough torque and the fitting will get loose and leak

over time, and too much torque will permanently damage the plastic

thread. Ideally, you want to add one quarter of a turn after the fitting

has reached its mating surface.

WARNING:

NEVER install the upper and lower barb fittings in the same vertical

alignment, or there will be no flow to the water-blocks!

Example 1: both inlet and outlet go

ports go upwards

Example 2: one port goes upwards,

and one port goes downwards.