Gas requirements, Warning – Alliance Laundry Systems T433I User Manual

Page 37

35

M414038

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Gas Requirements

IMPORTANT: Any product revisions or conversions

must be made by the Manufacturer’s Authorized

Dealers, Distributors or local service personnel.

IMPORTANT: The installation must comply with

local codes or, in the absence of local codes:

●

with the latest edition of the “National Fuel

Gas Code,” ANSI Z223.1/NFPA 54 in the

U.S.A.,

●

with CSA-B149.1 Natural Gas and Propane

Installation Code in Canada,

●

and Australian Gas Association/Australian

L.P. Gas Association requirements in

Australia.

Obtain specific gas service pipe size from the gas

supplier. Refer to Table 7 for general pipe size.

A dirt and water vapor pipe trap must be furnished and

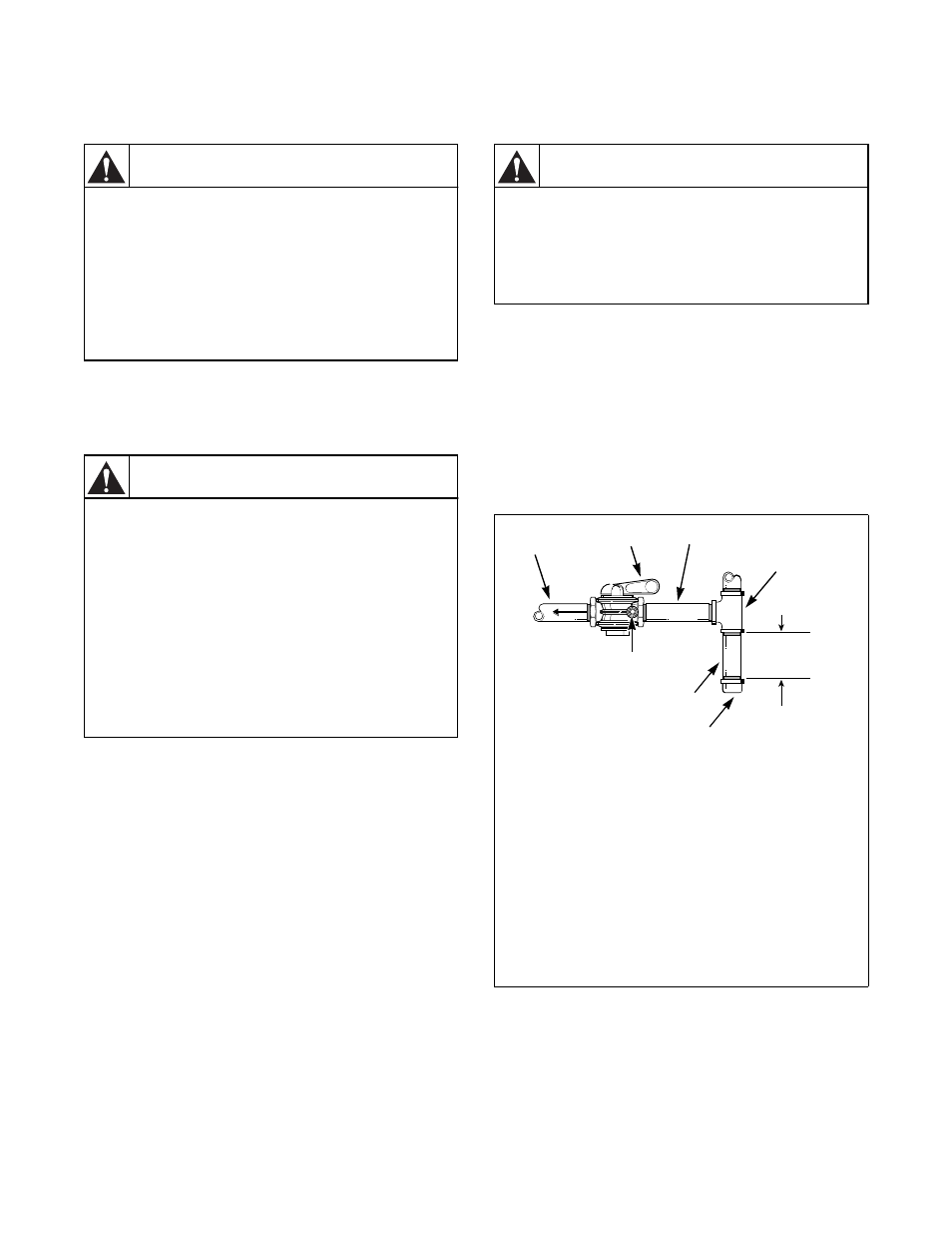

installed by customer. Refer to Figure 13.

Install a 1 inch (25.4 mm) pipe gas loop to maintain

equal pressure at all gas connections. Refer to

Figure 14.

NATURAL GAS service must be supplied at 7.0 ±

1.5 inch water column pressure (1.74 ± 0.37 kPa).

L.P. (Liquefied Petroleum) GAS service must be

supplied at 11 ± 0.3 inch water column pressure

(2.74 ± 0.07 kPa).

EUROPEAN GASES – The above data for Natural

and L.P. Gas does not apply in the EU. Refer to

Installing Gas Drying Tumblers in the European

Union Section.

Figure 13

WARNING

To reduce the risk of fire or explosion, DO

NOT CONNECT THE GAS LINE TO THE

TUMBLER IF THE GAS SERVICE IS NOT

THE SAME AS THAT SPECIFIED ON THE

TUMBLER SERIAL PLATE! It will first be

necessary to convert the gas burner

orifice and gas valve. Appropriate

conversion kits are available.

W060

WARNING

The tumbler and its individual shut-off

valve must be disconnected from the gas

supply piping system during any

pressure testing of that system at test

pressures in excess of 1/2 psig (3.45 kPa).

The tumbler must be isolated from the

gas supply piping system by closing its

individual manual shut-off valve during

any pressure testing of the gas supply

piping system at test pressure equal to or

less than 1/2 psig (3.45 kPa).

W061

T135I

1

Gas Line to Tumbler Controls

2

Shut-Off Valve

3

Gas Supply Piping System

4

Gas “T” Fitting

5

6 in. (152 mm) Minimum Gas Pipe

6

Gas Pipe Cap

7

Dirt and Water Vapor Trap

8

1/8 in. (3.2 mm) NPT plugged tapping

accessible for pressure testing. Gauge

connection located upstream from tumbler

gas supply connection.

WARNING

To reduce the risk of fire or explosion, if

the tumbler is to be connected to

Liquefied Petroleum (L.P.) gas, a vent to

the outdoors must be provided in the

room where the tumbler is installed.

W062

T378I

1

2

3

4

5

6

7

8