Iring, Ontroller, Wiring connections – Red Lion PXU User Manual

Page 7: Controller power connections, Input connections, Control and alarm output connections

77

3.0 W

iring

The

C

OnTrOller

WIRING CONNECTIONS

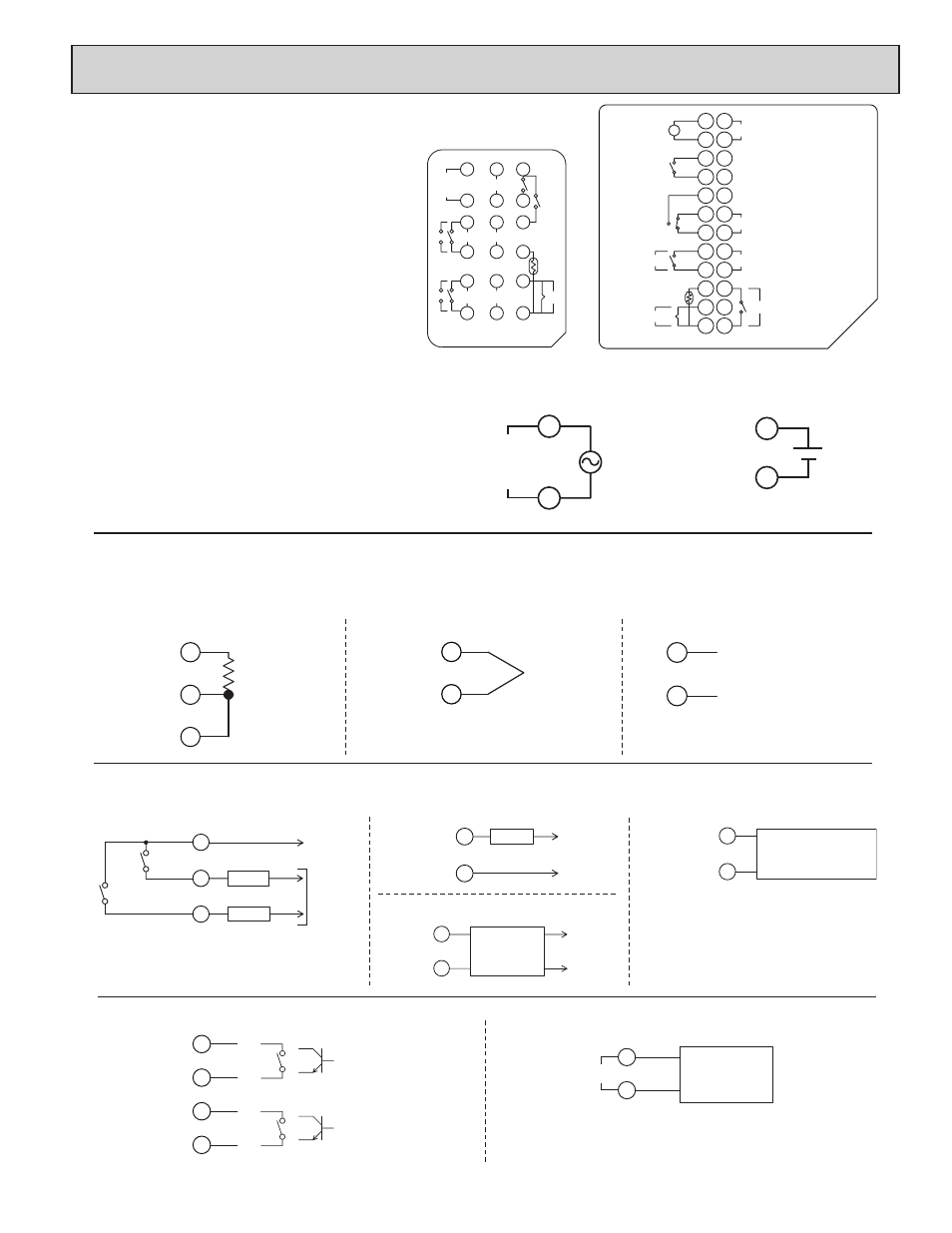

All wiring connections are made to the rear screw terminals.

When wiring the controller, use the numbers on the label and

those embossed on the back of the case, to identify the position

number with the proper function.

All conductors should meet voltage and current ratings for

each terminal. Also, cabling should conform to appropriate

standards of good installation, local codes and regulations. It is

recommended that power (AC or DC) supplied to the controller

be protected by a fuse or circuit breaker. Strip the wire, leaving

approximately 1/4" (6 mm) bare wire exposed (stranded wires

should be tinned with solder). Insert the wire under the clamping

washer and tighten the screw until the wire is clamped tightly.

1

L

50/60 Hz

5VA

AC 100-240V

N

2

13

14

User1

8

7

+

-

15

9

3

User 2

4

10

16

AL1

AL2

OP 2 / AL 3

+

-

11

17

5

12

18

6

RTD

OP 1

RS-485

D

D

-

+

+

IN

Tc

+

- -

+

-

-

+

AC 100~240V

50/60 Hz

5VA

1

~

13

2 14

3 15

4 16

5 17

6 18

7 19

8 20

9 21

10 22

11 23

12 24

IN Tc

NO

D-

L

N

NO

D+

RS-485

NO

NO

&200

&200

&200

&200

NC

AL 1

AL 2

OP 1

User 2

User 1

OP 2/ AL 3

+

+

+

+

+

+

-

-

-

-

-

-

1/16 DIN

1/8 or 1/4 DIN

CONTROLLER POWER CONNECTIONS

For best results, the power should be relatively “clean” and within

the specified limits. Drawing power from heavily loaded circuits or

from circuits that also power loads that cycle on and off should be

avoided. It is recommended that power supplied to the controller be

protected by a fuse or circuit breaker.

2

1

L

N

AC 100-240V

50/60 Hz

5VA

INPUT CONNECTIONS

For two wire RTDs, install a copper sense lead of the same gauge and length

as the RTD leads. Attach one end of the wire at the probe and the other end to

input common terminal. This is the preferred method as it provides complete

lead wire compensation. If a sense wire is not used, then use a jumper. A

temperature offset error will exist. The error may be compensated by

programming a temperature offset.

12

11

10

TC-

TC+

12

11

DC+ VOLTAGE/CURRENT

DC- VOLTAGE/CURRENT

12

11

CONTROL AND ALARM OUTPUT CONNECTIONS

VAC

RTD and Resistance

Thermocouple and Millivolt

Voltage and Current

LOAD

AC/DC

Power (-)

LOAD

COMM

NO

NO

AC/DC

Power (+)

AL 2

AL 1

AC/DC

Power

LOAD

COMM (-)

NO (+)

AC Power

SSR

COMM (-)

NO (+)

POWER

UNIT

+

-

AC

AC

Alarm 1 and 2 * (1/16 DIN Shown)

OP1/OP2 Output Control Relay *

OP1 Output Control Logic/SSR *

USER INPUT CONNECTIONS *

User 1

+

User 2

+

-

-

* See unit label for terminal identification.

RS 485 CONNECTIONS *

D+

D-

RS485

RECEIVING

DEVICE

+

-

RS-485

0 V

DC 24V

2

1

+

_

VDC

ANALOG INPUT

CONTROL

DEVICE

COMM (-)

NO (+)

IN +

IN -

OP1 Output Control Analog *