Nstalling, Ontroller – Red Lion PXU User Manual

Page 6

6

2.0 i

nsTalling

The

C

OnTrOller

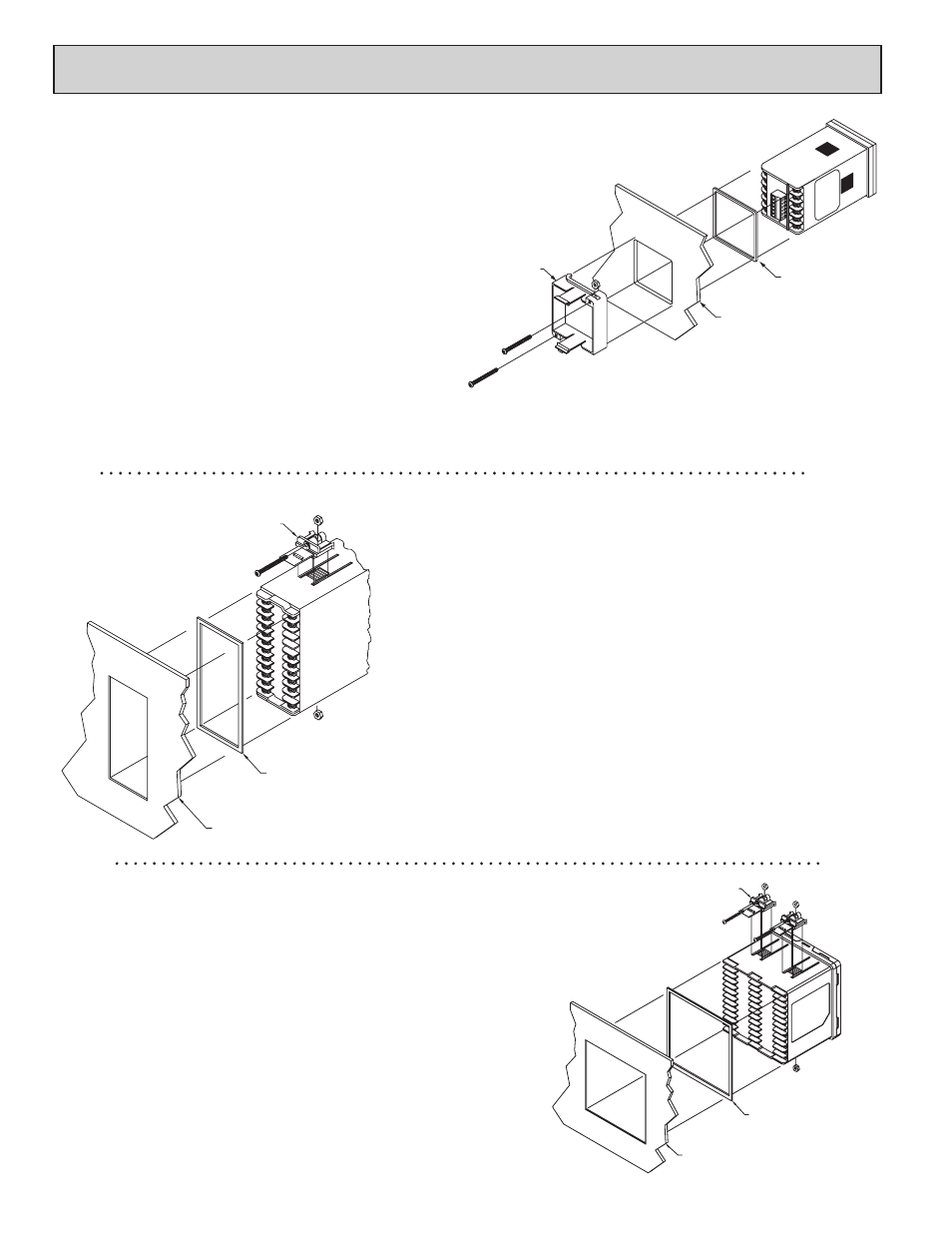

The controller is designed to be mounted into an enclosed panel. The

unit must be inserted in the case during installation of the controller.

Instructions:

1. Prepare the panel cutout to the proper dimensions.

2. Assemble the mounting clip by inserting the nut into the slot and then

insert the screw and thread through the nut as shown (See drawing)

3. Slide the panel gasket over the rear of the controller, seating it against

the lip at the front of the case.

4. Insert the controller into the panel cutout. While holding the controller

in place, install the panel latch and then slide it to the farthest forward

slot possible.

5. To achieve a proper seal, tighten the panel latch screws evenly until

the controller is snug in the panel, torquing the screws to 13.9 to 20.8

oz-in (9.8 to 14.7 N-cm). Overtightening can result in distortion of the

controller, and reduce the effectiveness of the seal.

Note: The installation location of the controller is important. Be sure to

keep it away from heat sources (ovens, furnaces, etc.) and away from

direct contact with caustic vapors, oils, steam, or any other process

by-products in which exposure may affect proper operation.

(4) PANEL LATCH

(SUPPLIED W/UNIT)

PANEL

GASKET

EXISTING PANEL CUT-OUT

3.58" (91.0 mm) X 3.58" (91.0 mm)

7

8

9

10

11

12

PANEL LATCH

(SUPPLIED W/UNIT)

EXISTING PANEL CUT-OUT

1/16 DIN

1.77” (45.0 mm) X 1.77” (45.0 mm)

PANEL GASKET

1/16 DIN Installation

1/8 DIN Installation

1/4 DIN Installation

20

24

23

22

21

14

17

19

18

15

16

13

(2) PANEL LATCH

(SUPPLIED W/UNIT)

PANEL

GASKET

EXISTING PANEL CUT-OUT

1.76" (44.5 mm) X 3.60" (91.5 mm)

The controller is designed to be mounted into an enclosed panel. The unit must be inserted

in the case during installation of the controller.

Instructions:

1. Prepare the panel cutout to the proper dimensions.

2. Assemble the mounting clip by inserting the nut into the slot and then insert the screw and

thread through the nut as shown (See drawing)

3. Slide the panel gasket over the rear of the controller, seating it against the lip at the front of

the case.

4. Insert the controller into the panel cutout. While holding the controller in place, install the

panel latches and then slide them to the farthest forward slot possible.

5. To achieve a proper seal, tighten the panel latch screws evenly until the controller is snug

in the panel, torquing the screws to 13.9 to 20.8 oz-in (9.8 to 14.7 N-cm). Overtightening

can result in distortion of the controller, and reduce the effectiveness of the seal.

Note: The installation location of the controller is important. Be sure to keep it away from heat

sources (ovens, furnaces, etc.) and away from direct contact with caustic vapors, oils,

steam, or any other process by-products in which exposure may affect proper operation.

The controller is designed to be mounted into an enclosed panel. The unit must be inserted

in the case during installation of the controller.

Instructions:

1. Prepare the panel cutout to the proper dimensions.

2. Assemble the mounting clip by inserting the nut into the slot and then insert the screw and

thread through the nut as shown (See drawing)

3. Slide the panel gasket over the rear of the controller, seating it against the lip at the front

of the case.

4. Insert the controller into the panel cutout. While holding the controller in place, install the

panel latches and then slide them to the farthest forward slot possible.

5. To achieve a proper seal, tighten the panel latch screws evenly until the controller is snug

in the panel, torquing the screws to 13.9 to 20.8 oz-in (9.8 to 14.7 N-cm). Overtightening

can result in distortion of the controller, and reduce the effectiveness of the seal.

Note: The installation location of the controller is important. Be sure to keep it away from

heat sources (ovens, furnaces, etc.) and away from direct contact with caustic vapors, oils,

steam, or any other process by-products in which exposure may affect proper operation.