2 module 2 - s, Econdary, Unction – Red Lion PAXLT User Manual

Page 7: Arameters

7

5.2 Module 2 - s

econdary

F

unction

p

araMeters

(

)

PAR

Max Capture

Delay Time

Max Display

Enable

Min Display

Enable

Access Code

For Service

Operations

Min Capture

Delay TIme

Factory

Service

Operations

2-SEC

HI-En

HI-t

LO-En

LO-t

FCS

CodE

Pro

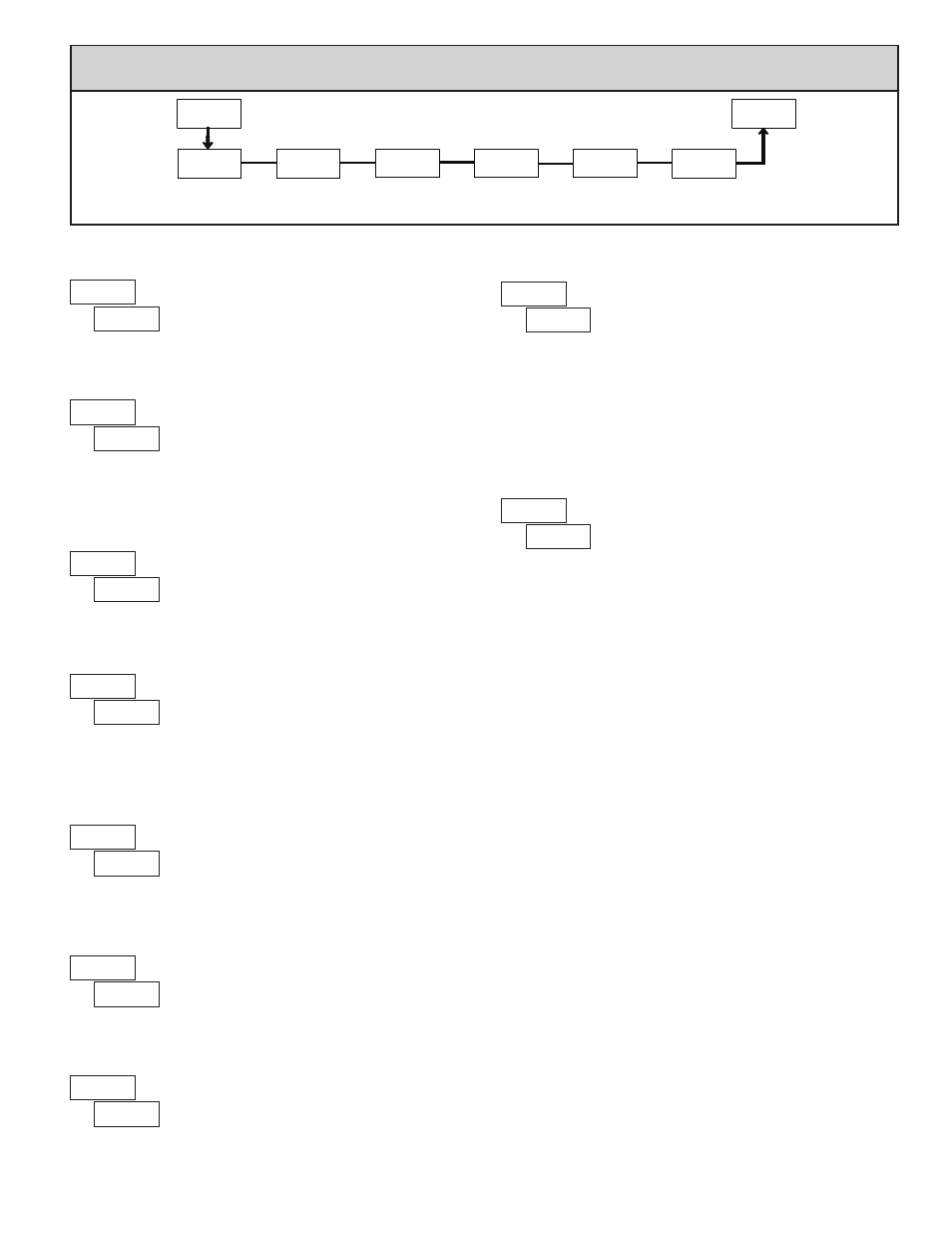

PARAMETER MENU

MIN DISPLAY ENABLE

MIN CAPTURE DELAY TIME

When the Input Display is below the present MIN value for the entered delay

time, the meter will capture that display value as the new MIN reading. A delay

time helps to avoid false captures of sudden short spikes.

to

sec.

Enables the Minimum Display Capture capability.

MAX CAPTURE DELAY TIME

When the Input Display is above the present MAX value for the entered

delay time, the meter will capture that display value as the new MAX reading.

A delay time helps to avoid false captures of sudden short spikes.

to

sec.

MAX DISPLAY ENABLE

Enables the Maximum Display Capture capability.

Entering Code 66 will overwrite all user settings with

the factory settings. The meter will display

and then

return to

. Press the

PAR

button to exit the module

Select

to perform any of the Factory Service Operations shown below.

FACTORY SERVICE OPERATIONS

RESTORE FACTORY DEFAULT SETTINGS

Entering Code 50 will display the version (x.x) of the

meter. The display then returns to

. Press the

PAR

button to exit the module.

VIEW MODEL AND VERSION DISPLAY

Entering Code 85 toggles the selected RTD input display

mode between a temperature or resistance readout. The

resistance readout is useful for diagnostic purposes before

and after calibration, or to display the measured resistance

of a connected RTD probe.

For RTD type

(Input Range Jumper in 10Ω position), resistance is

displayed in

ohms resolution. For all other RTD types (100Ω position),

resistance is displayed in

ohms resolution.

Upon entering Code 85, the meter displays either

or

to indicate

temperature or resistance readout selected. The display then returns to

.

Press the

PAR

button to exit the module.

TOGGLE RTD INPUT DISPLAY MODE

The PAXLT uses stored calibration values to provide

accurate temperature measurements. Over time, the

electrical characteristics of the components inside the

meter could slowly change, with the result being that the

stored calibration values may no longer accurately define

the input circuit. For most applications, recalibration every 1 to 2 years should

be sufficient.

Calibration for thermocouple inputs involves a voltage calibration and a cold

junction calibration. It is recommended that both calibrations be performed. The

voltage calibration must precede cold junction calibration.

Calibration of the meter should only be performed by persons experienced in

calibrating electronic equipment. Allow a minimum 30 minute warm up before

performing any calibration procedures. The following procedures should be

performed at an ambient temperature of 15 to 35°C (59 to 95°F).

CAUTION: The accuracy of the calibration equipment will directly affect the

accuracy of the meter.

10 OHM RTD Range Calibration

1. Set the Input Range Jumper to 10 ohm position.

2. With the display at

, press the

PAR key. Unit displays

.

3. Press

SEL to select 10 ohm range. Display reads

.

4. Press

PAR. Display reads

.

5. Apply a direct short to terminals RTD (4), TC (6) and COMM (7) using a

three wire link. Press

PAR. Display reads

for about 10 seconds.

6. When the display reads

, apply a precision resistance of 15 ohms (with

an accuracy of 0.01% or better) to terminals RTD, TC and COMM using a

three wire link. Press

PAR. Display reads

for about 10 seconds.

7. When display reads

, press

PAR twice to exit calibration and return to

the normal display mode.

100 OHM RTD Range Calibration

1. Set the Input Range Jumper to 100 ohm position.

2. With the display at

, press the

PAR key. Unit displays

.

3. Press

SEL twice to select 100 ohm range. Display reads

.

4. Press

PAR. Display reads

.

5. Apply a direct short to terminals RTD (4), TC (6) and COMM (7) using a

three wire link. Press

PAR. Display reads

for about 10 seconds.

6. When the display reads

, apply a precision resistance of 300 ohms (with

an accuracy of 0.01% or better) to terminals RTD, TC and COMM using a

three wire link. Press

PAR. Display reads

for about 10 seconds.

7. When display reads

, press

PAR twice to exit calibration and return to

the normal display mode.

CALIBRATION