Iring, Eter, Etting – Red Lion PAXLT User Manual

Page 3: Umper, Nstalling

3

3.0 W

iring

the

M

eter

WIRING OVERVIEW

Electrical connections are made via screw-clamp terminals located on the

back of the meter. All conductors should conform to the meter’s voltage and

current ratings. All cabling should conform to appropriate standards of good

installation, local codes and regulations. It is recommended that the power

supplied to the meter (DC or AC) be protected by a fuse or circuit breaker.

When wiring the meter, compare the numbers embossed on the back of the

meter case against those shown in wiring drawings for proper wire position. Strip

the wire, leaving approximately 0.3" (7.5 mm) bare lead exposed (stranded wires

should be tinned with solder.) Insert the lead under the correct screw-clamp

terminal and tighten until the wire is secure. (Pull wire to verify tightness.)

EMC INSTALLATION GUIDELINES

Although Red Lion Controls Products are designed with a high degree of

immunity to Electromagnetic Interference (EMI), proper installation and wiring

methods must be followed to ensure compatibility in each application. The type

of the electrical noise, source or coupling method into a unit may be different

for various installations. Cable length, routing, and shield termination are very

important and can mean the difference between a successful or troublesome

installation. Listed are some EMI guidelines for a successful installation in an

industrial environment.

1. A unit should be mounted in a metal enclosure, which is properly connected

to protective earth.

2. Use shielded cables for all Signal and Control inputs. The shield connection

should be made as short as possible. The connection point for the shield

depends somewhat upon the application. Listed below are the recommended

methods of connecting the shield, in order of their effectiveness.

1.0 i

nstalling

the

M

eter

2.0 s

etting

the

J

uMper

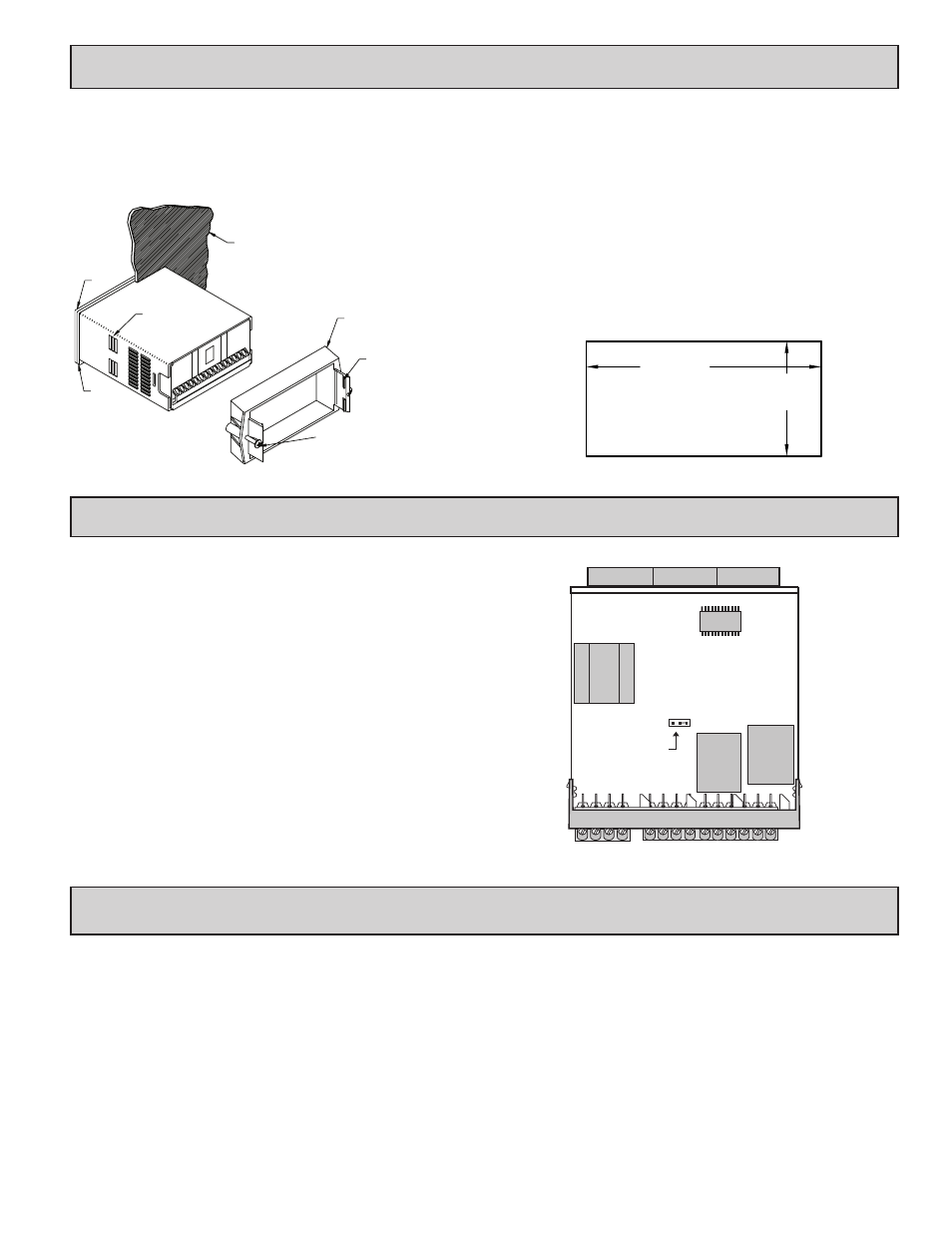

INPUT RANGE JUMPER (RTD ONLY)

This jumper is used to select the proper input range for the RTD probe being

used (10 ohm or 100 ohm). For thermocouple inputs, this jumper has no effect

and can be left in either position.

To access the jumper, remove the meter base from the case by firmly

squeezing and pulling back on the side rear finger tabs. This should lower the

latch below the case slot (which is located just in front of the finger tabs). It is

recommended to release the latch on one side, then start on the other side latch.

Main

Circuit

Board

REAR TERMINALS

FRONT DISPLAY

RTD RANGE

JUMPER

10 OHM

100 OHM

Installation

The PAX Lite meets NEMA 4X/IP65 requirements when properly installed.

The unit is intended to be mounted into an enclosed panel. Prepare the panel

cutout to the dimensions shown. Remove the panel latch from the unit. Slide the

panel gasket over the rear of the unit to the back of the bezel. The unit should

be installed fully assembled. Insert the unit into the panel cutout.

While holding the unit in place, push the panel latch over the rear of the unit

so that the tabs of the panel latch engage in

the slots on the case. The panel latch

should be engaged in the farthest

forward slot possible. To

achieve a proper seal,

tighten the latch

screws evenly

until the unit is snug in the panel (Torque to approximately 7 in-lbs [79N-cm]).

Do not over-tighten the screws.

Installation Environment

The unit should be installed in a location that does not exceed the maximum

operating temperature and provides good air circulation. Placing the unit near

devices that generate excessive heat should be avoided.

The bezel should be cleaned only with a soft cloth and neutral soap product.

Do NOT use solvents. Continuous exposure to direct sunlight may accelerate the

aging process of the bezel.

Do not use tools of any kind (screwdrivers, pens, pencils, etc.) to operate the

keypad of the unit.

PANEL

GASKET

BEZEL

PANEL

MOUNTING

SCREWS

LATCHING

SLOTS

PANEL

LATCHING

TABS

PANEL

LATCH

-.00

(92 )

-.0

+.8

3.62

+.03

(45 )

1.77

-.0

+.5

-.00

+.02

PANEL CUT-OUT