Front installation – JKS 2943 User Manual

Page 4

JKS2943

JKS Adjustable Sway Bar Links Installation

4 Page

IMPORTANT: It should not be necessary to grind

all the way through the steel bracket. Only re-

move enough material to eliminate the interfer-

ence problem.

Once sufficient clearance has been established,

apply spray paint to any bare metal on control arm

bracket to prevent corrosion.

Reinstall Adjustable End Link on swaybar and

tighten per the instructions earlier in this section.

5. TEST FOR INTERFERENCE

Before driving vehicle, compress the rear suspen-

sion to check for interference between the Adjust-

able End Links and chassis-mounted brake lines.

If any interference occurs, take corrective action

by utilizing one of the following methods:

Add or adjust bump stop height of rear suspension

to prevent upper Rod Ends (B) from contacting

brake lines.

Reduce length of Adjustable End Links by remov-

ing additional thread material from the Connecting

Rod (A). Remove only as much thread material as

necessary to eliminate interference. If Adjustable

End Links are too short, rear suspension travel will

be restricted.

Carefully bend the brake lines inward (toward

chassis) to gain approximately 0.25” of additional

clearance.Front Installation

Front Installation

1. REMOVE ORIGINAL EQUIPMENT

(OE) FRONT SWAYBAR LINKS

Remove the original mounting hardware that

secures the front swaybar links to the swaybar and

axle.

Discard original front swaybar links and mounting

hardware.

2. DETERMINE PROPER LENGTH OF

ADJUSTABLE END LINKS

The Adjustable End Links can be adjusted to any

length between 8.75” and 15” (measured from center-

to-center of rod ends). Adhere to the following instruc-

tions carefully to ensure that your Adjustable End

Links are set to the correct length.

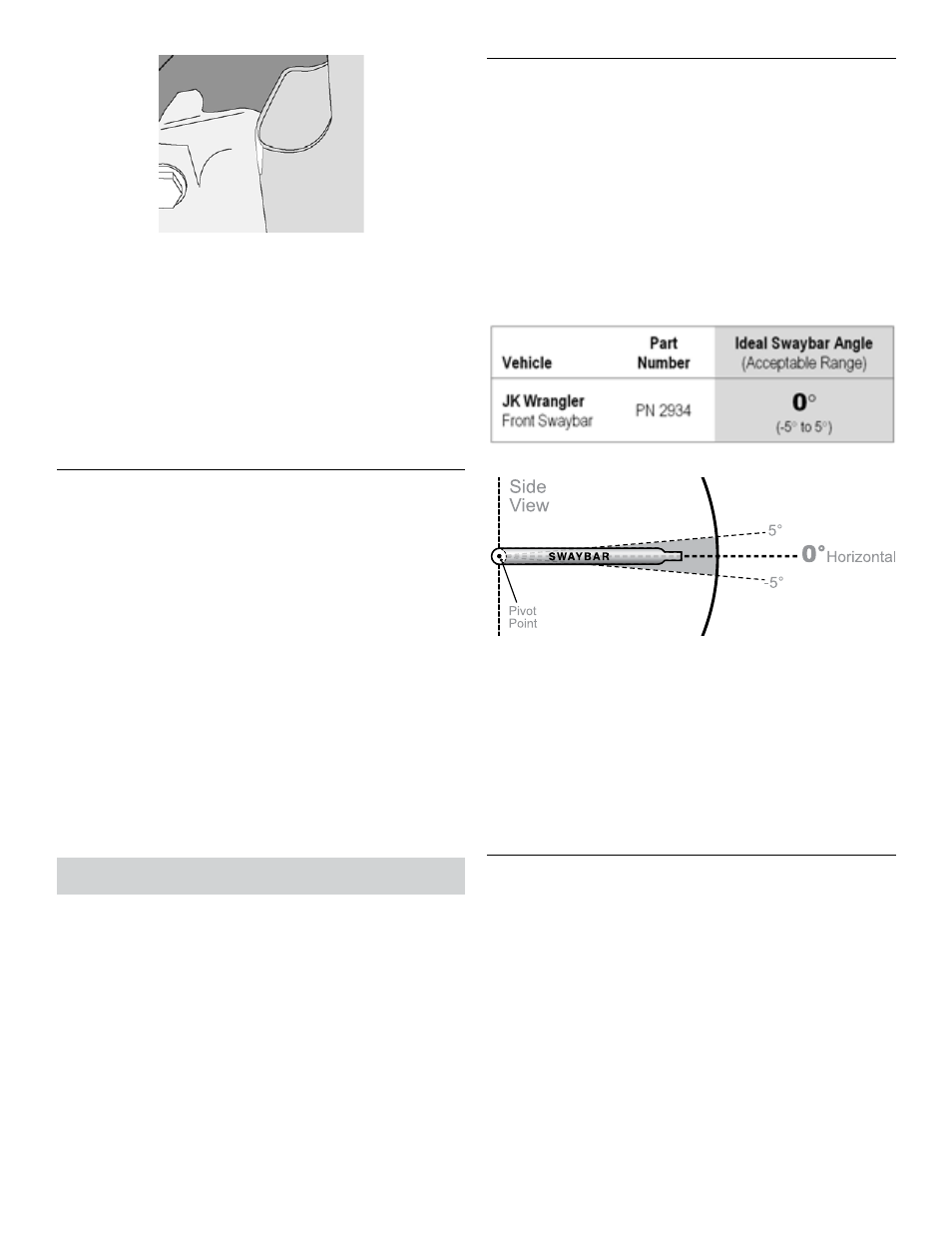

Rotate the front swaybar to the Ideal Angle (or

within Acceptable Range) listed below. Vehicle

must be at normal ride height and located on level

ground.

While holding the swaybar at the proper angle,

measure the distance between the center of the

original mounting holes on the swaybar and axle

bracket.

Subtract 2.25” from the distance recorded above

to determine the correct length of the Connecting

Rod (A).

HINT: For instance, if the center-to-center

distance for your application is 10”, the Connecting

Rod length should be 7.75”.

3. MODIFY CONNECTING ROD

Now that you know the correct Connecting Rod (A)

length for your application, subtract the length from

the overall Connecting Rod length of 12.75” and

then divide by 2 to determine the amount of mate-

rial to remove from each end.

HINT: For instance, if the correct Connecting Rod

length for your application is 7.75”, the amount

of material to remove from each end will be 2.5”.

Example 12.75 - 7.75 = 5 and 5 ÷ 2 = 2.5”

Remove Rod Ends (B) from both ends of the Con-

necting Rod (A). Do not remove 1/2” Jam Nuts (C).