JKS 2943 User Manual

Page 3

JKS2943

JKS Adjustable Sway Bar Links Installation

Page 3

HINT: Remove same amount of thread material

from each end.

Using an appropriate cutting tool (such as a die

grinder with cutting wheel, or metal cutting saw),

carefully and squarely cut each end of the Con-

necting Rod (A) where previously marked.

Now completely unthread both 1/2” Jam Nuts (C)

from Connecting Rod (A) and re-install.

HINT: This

will help to repair any thread damage that may

have occurred during the cutting process.

Apply a drop of medium strength thread locking

compound to the tip of threads at each end of

Connecting Rod (A).

Completely thread a Rod End (B) on to each end

of Connecting Rod.

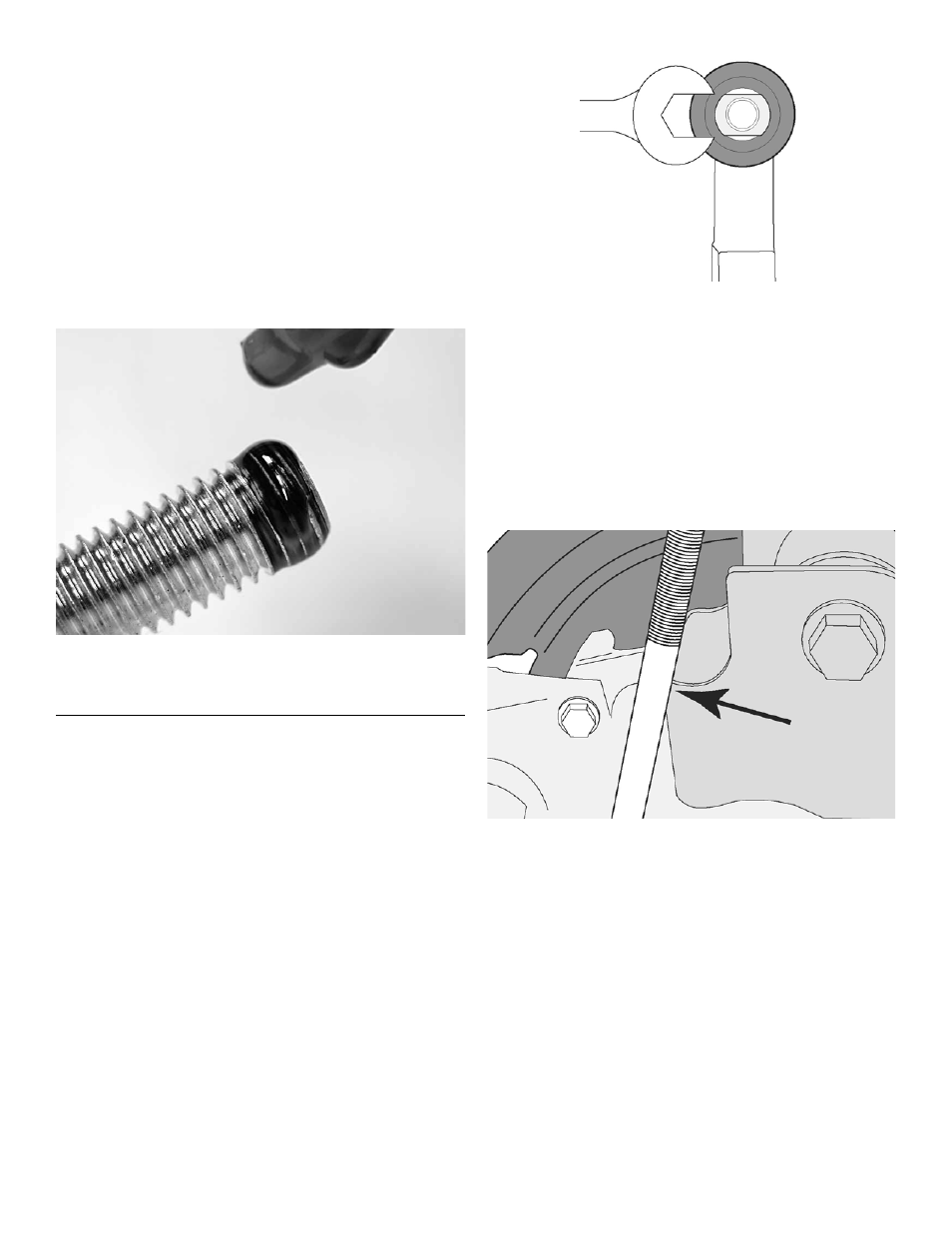

4. INSTALL END LINKS

Using the supplied 1/2” Flanged Locking Nuts (D),

secure the Adjustable End Links to the swaybar

and axle bracket. Make sure upper and lower Rod

Ends (B) are in alignment with their respective

mounting surfaces.

IMPORTANT: End Links must be installed on out-

board side of swaybar and axle bracket.

Once all adjustments are complete, fully tighten

the Jam Nuts (C) against the Rod Ends (B) to pre-

vent length of Adjustable End Links from changing.

Tighten the 1/2” Flanged Locking Nuts (D) to 40

ft-lbs. using a torque wrench.

HINT: Use flat spot on Rod Ends (B) to prevent

mounting stud from spinning when tightening 1/2”

Flanged Locking Nut (D).

On the upper Rod Ends (B) only, cut the excess

thread material from the mounting stud so that

none of the threaded portion protrudes beyond

Flanged Locking Nut (D).

On vehicles in which the rear axle housing has been

rotated to correct the pinion angle following a CV

driveshaft installation, there may be insufficient clear-

ance between the upper control arm bracket on the

axle and the Connecting Rod (A).

Check for interference where indicated by the ar-

row in the illustration below.

If interference between the control arm bracket and

Connecting Rod (A) is discovered, it will be necessary

to clearance the bracket per the following instructions.

Locate the area of interference and mark the loca-

tion on both upper control arm brackets.

Temporarily remove the Adjustable End Link from

the swaybar to provide access to the control arm

bracket.

Remove just enough material from the control arm

bracket to prevent the Connecting Rod (A) from

contacting it.

HINT: A die grinder or metal grind-

ing wheel is useful for removing material from the

control arm bracket.