2 earth rail and tagging accessories – Dwyer MTL5045 User Manual

Page 8

4

INM5000-6 Jul 2010

3.1.5. Relay outputs

Reactive loads on all units with relays should be adequately

suppressed.Changeover relay outputs are provided on the following

units: MTL5011B, MTL5014, MTL5018 and MTL5314. In order to

achieve maximum contact life, a minimum switching current of 10mA at

≥5V is recommended.

3.1.6

Earth leakage detection

An MTL4220 earth leakage detector can be used with a number of

MTL5000 Series units to detect hazardous-area earth faults which can

then be rectified without needing to shut down the loop ('no-fail'

operation). On units with a single-channel input, the MTL4220 is

connected to terminal 3 and on units with two-channel inputs, to

terminals 3 and 6. Units which can be used with an MTL4220 are:

MTL5011B

MTL5012

MTL5014

MTL5015

MTL5017

MTL5018

MTL5021

MTL5022

MTL5023

MTL5024

MTL5025

MTL5061

N.B. HAZ1-3 or HAZ4-6 connectors are required.

3.1.7

Ambient temperature considerations

Ambient temperature limits for unenclosed MTL5000 Series isolators are

from -20°C to +60°C with units close-packed.

4

ACCESSORIES

4.1

MTL5000 power bus - Installation

and use

4.1.1

MTL5000 Series power bus

Power bus kits provide facilities for linking the power supply terminals

(13 and 14) of up to 32 installed MTL5000 Series units to a standard

24V power supply. Buses consist of chains of power plugs and are

available in different lengths to suit various numbers of modules as

follows:

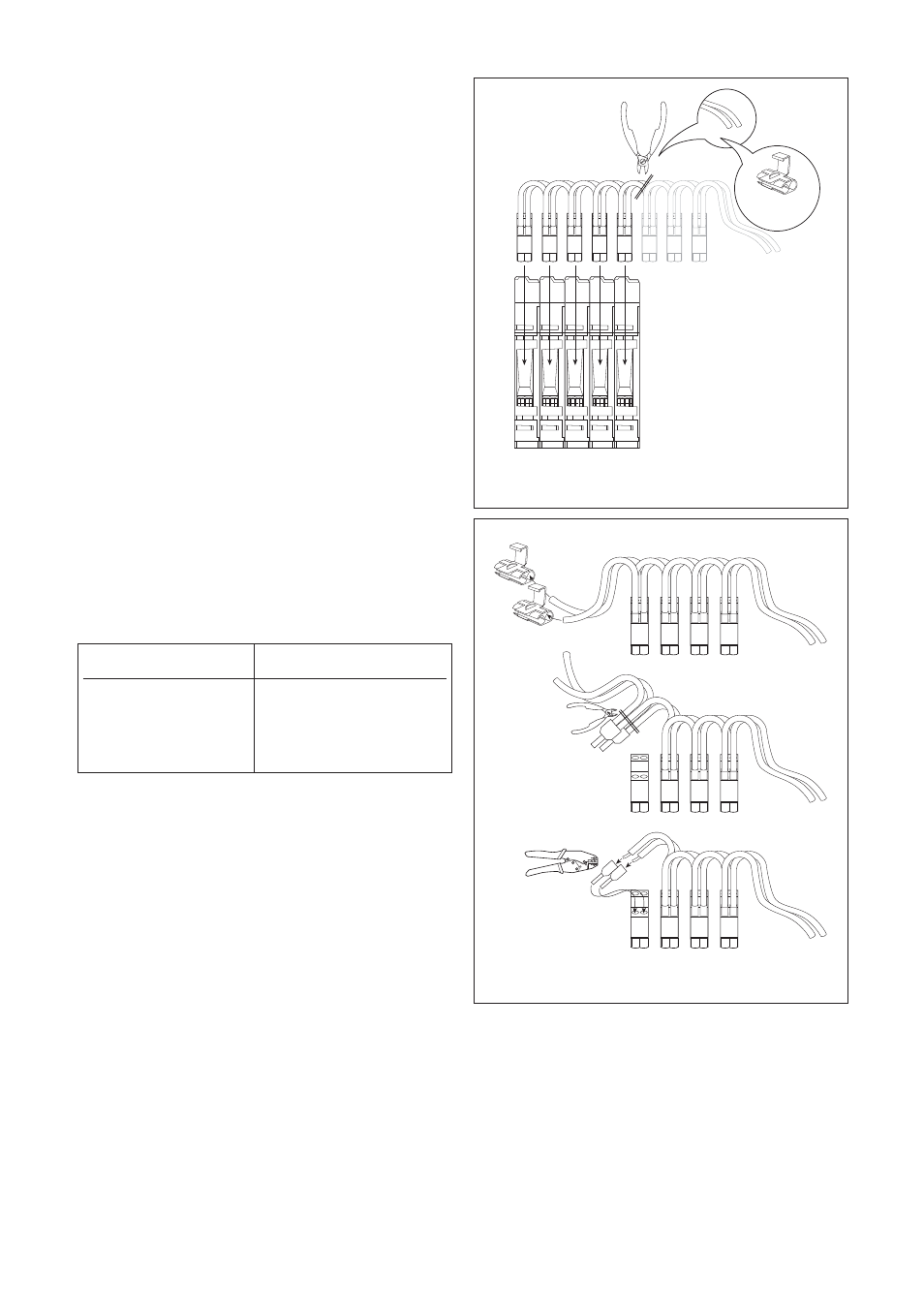

4.1.2. Installation

4.1.2.1

Check to make sure the bus length is correct for the

number of modules involved.

4.1.2.2

If the number of modules is less than the maximum number

the chain will support, cut off the surplus power plugs at

the tail end of the chain - leaving a 'new' tail end.

4.1.2.3

Insert power plugs into the power terminals on the safe-

area side of each module in sequence.

4.1.2.4

Connect the power supply source to the tail end of the

chain (using the insulation displacement connectors

(Scotchloks) provided if required).

Notes:

1. To reduce the risk of excessive voltage drop or over-

current, DO NOT connect power buses in series.

2. Surplus sections can be used (and, if required)

connected together provided the cut ends are safely

terminated and/or connected together. Use single

ferrules with a crimp tool or insulation displacement

connectors (Scotchloks). Suitable ferrules and connectors

are provided with the kits.

4.2

Earth rail and tagging accessories

This section explains how to specify and assemble earth rail and tagging

strip accessories for the MTL5000 Series.

The accessories consist of mounting brackets, earth rails, tagging strips

and associated parts. They provide facilities for earthing, terminating

cable screens and tagging (identifying) the positions of individual units.

4.2.1

Parts list

IMB57 Insulating mounting block (figure 4.5)

One required at each end of a tagging strip/earth rail. Suitable for low-

profile (7.5mm) and high-profile (15mm) symmetrical DIN rail.

ERB57S Earth-rail bracket, straight (figure 4.6)

Nickel-plated; supplied with two push fasteners, one earth-rail clamp

(14mm, 35mm

2

) and one earth cable clamp (10mm, 16mm

2

).

Note: ERB57S is the preferred choice of earth-rail bracket. It is usually

fitted in the upper slot on insulating mounting block IMB57.

Number of modules

Kit ID code

(contains grey power plugs for 24V dc supply)

1 to 8

PB-8T

9 to 16

PB-16T

17 to 24

PB-24T

25 to 32

PB-32T

+

Optional insulation

displacement

connectors

x2

OR

Figure 4.1: Installing a chain of power plugs into MTL5000

Series modules

Figure 4.2: Using crimp ferrules or insulation displacement

connectors (Scotchloks) to terminate cut ends