Dwyer GFT2 User Manual

Page 5

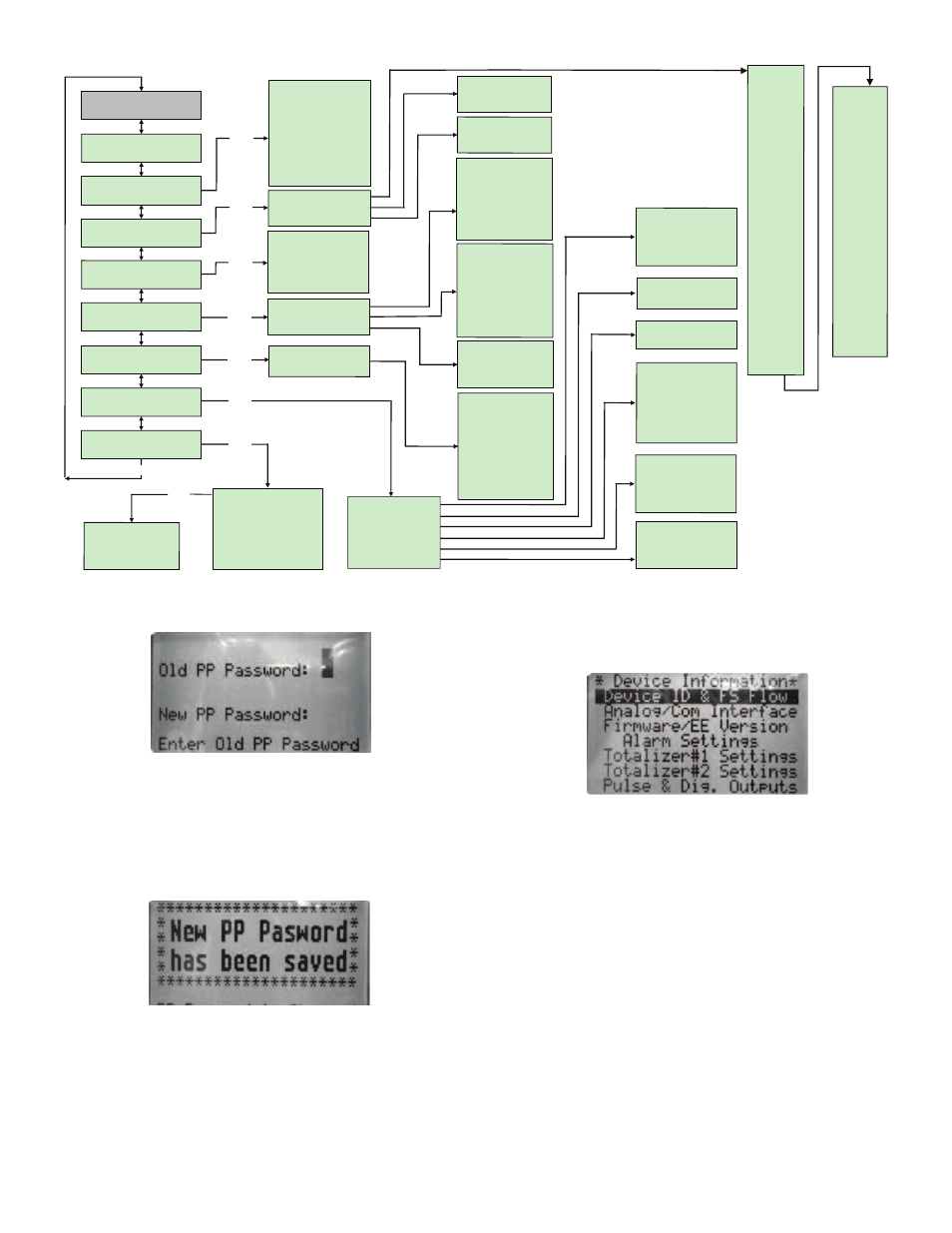

Once “Change PP Password” menu is selected, the following screen will appear:

In order to protect device configuration parameters when changing the PP

password, the old PP password must be entered.

NOTE: By default, the device shipped from the factory with Program Protection

(PP) password set to Zero (PP Disabled).

Once old and new passwords are entered, the firmware will prompt with a

confirmation message (see Figure 12) that the new password has been saved.

Submenu “Device Information”

This submenu contains information about the device’s main configuration

parameters. These items are informational only, not password-protected, and can

not be changed (read only).

Submenu “Measuring Units”

Use the “Engineering Units and K-Factor Menu” to navigate to “Measuring Units”

menu option. This option allows configuration of the flow meter/controller with the

desired units of measurement. These are global settings and determine what

appears on all process information screens and data log records. Units should be

selected to meet each particular metering need. A total of 47 different volumetric

and mass based engineering units are supported (See Table 4).

NOTE: Program the Measuring Units first because subsequent menus may be

based on the units selected. Once Flow Unit of Measure is changed, the Totalizer’s

Volume based Unit of Measure will be changed automatically.

Program Protaction (PP)

Change PP Password

Device Information

EngUnits & K-Factor

Totalizer Settings

Opt Output Settings

General Settings

Device Diagnostic

Alarm Settings

***** Main Menu *****

Up/Dn

Event Register Menu

Analog Input counts

Analog Output Value

LCD Back Light Set.

Pulse Output Queue

CPU Temperature

Device Diagnostic

Opt Output #1 Set

Opt Output #2 Set

Totalizer #1

Totalizer #2

Pulse Output

Flow Alarm Mode

Low Flow Alarm

High Flow Alarm

Flow Alarm Delay

Flow Alarm Latch

Measuring Units

UserDefined Units

K-Factor Settings

Device ID & FS Flow

Analog/Com Interface

Firmware/EE Version

Alarm Settings

Totalizer#1 Settings

Totalizer#2 Settings

Pulse & Dig. Outputs

Mated Device Info

General Settings

Display Mode

Screen Cycle Time

Screen Mask

Display Back Light

Display Contrast

Flow Meter

Flow Controller

Baud Rate Settings

RS-485 Bus Address

Full Scale Range

Low Flow Cut-off

Flow PowerUp Delay

Fluid Std. Density

Analog Output Cal.

Analog Input Cal.

Pilot Cal. Timer

Signal Condit. Mode

NRF Num. of Samples

NRF Time Interval

Aver.Filter Damping

FlowLinearizer Mode

Program SP Mode

PSP Loop Mode

PSP Steps Mask

PSP Steps Settings

Totalizer #1 Mode

Tot#1 Flow Start

Tot#1 Action Vol.

Tot#1 PowerOn Delay

Tot#1 Auto Reset

Tot#1 AutoRes Delay

Reset Totalizer #1

Totalizer #2 Mode

Tot#2 Configuration

Tot#2 Flow Start

Tot#2 Action Vol.

Tot#2 PowerOn Delay

Tot#2 Auto Reload

Tot#2 AutoRel Delay

Reset Totalizer #2

PulseOutput Mode

Pulse Flow Start

[Unit]/Pulse

Pulse Active Time

Disabled

Low F. Alarm

High F. Alarm

F. Range H-L

Total#1 Event

Total#2 Event

Pulse Output

Diagnostic

Manual On

UD Unit K-Factor

UD Unit Time Base

UD Unit Use Density

K-Factor Mode

Int. K-Factor Index

User Def'd K-Factor

%FS

ml/sec

ml/min

ml/hr

ml/day

litr/sec

litr/min

litr/hr

litr/day

m^3/sec

m^3/min

m^3/hr

m^3/day

f^3/sec

f^3/min

f^3/hr

f^3/day

gal/sec

gal/min

gal/hr

gal/day

gram/sec

gram/min

gram/hr

gram/day

kg/sec

kg/min

kg/hr

kg/day

lb/sec

lb/min

lb/hr

lb/day

Mton/min

Mton/hr

Igal/sec

Igal/min

Igal/hr

Igal/day

MilL/min

MilL/hr

MilL/day

bbl/sec

bbl/min

bbl/hr

bbl/day

User

Ent

Event Reg. Status

Event Latch Mask

Event Reg. Mask

Reset Event Reg.

Display Settings

Device Function

Communication Sett.

Device Calibration

Signal Conditioner

Program Set Point

Ent

Ent

Ent

Ent

Ent

Ent

Ent

Figure 10

Figure 11

Figure 12

Figure 13