Dwyer GFT2 User Manual

Page 17

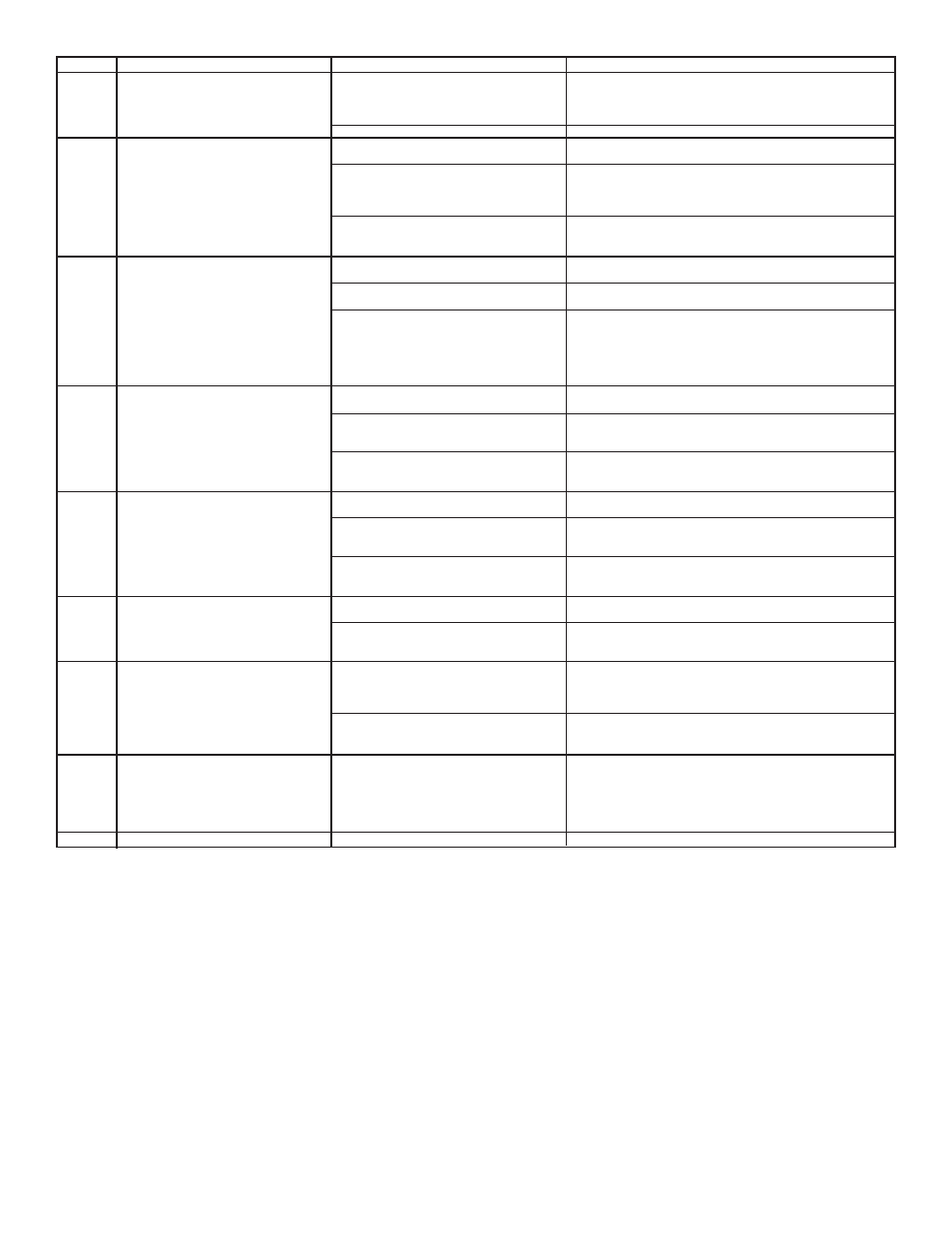

Number

1

2

3

4

5

6

7

8

9

Indication

LCD Display remains blank when unit is

powered up. Status LED is OFF.

LCD Displays flow reading, but 4 to 20

mA Set Point output signal does not

change.

Fluid flows throught he flow

meter/controller, but the LCD Display

and/or Totalizer reading does not

respond to the flow.

Fluid flows through the flow

meter/controller and LCD Display Flow

Rate reading responds to flow, but

Totalizer reading is not changing.

Erratic Flow Rate reading.

Totalizer reading is wrong.

LCD Displays flow reading, but

communication interface does not work.

The Device Diagnostic Alarm Event with

code 0 - "CPU Temp. High" is active.

The Device System Event with code D -

"Fatal Error" is active.

Likely Reason

Power Supply is bad, or polarity is reversed.

PC board is defective.

Wrong configuration of J2 Input/Output

Jumpers.

External loop is open, or load resistance is

more than 600 Ohm.

External loop is open, or load resistance is

more than 600 Ohm.

The fluid flow rate is below set Low Flow Cut-

Off value.

Wrong configuration of J2 Input/Output

Jumpers.

PC board is defective.

The fluid flow rate is below set "Totalizer #1

Flow Start" parameter value.

Totalizer mode is disabled.

Totalizer Power On Delay parameter is set to

high value and Totalizer is disabled by

firmware.

Wrong configuration of J2 Input/Output

Jumpers.

GFT2 "Full-Scale Flow" parameter value (in

L/min) is not equal to the mated device full-

scale range.

GFT2 "Fluid Std. Density" parameter is not set

according to fluid being used and mass based

engineering units are selected.

Wrong configuration of J2 Input/Output

Jumpers.

GFT2 "Full -cale Flow" parameter value (in

L/min) is not equal to the mated device full-

scale range.

Wrong host PC interface or wiring connection.

GFT2 has RS-485 interface but device

address does not match addressed used by

host PC.

MCU/PCB temperature is too high (overload).

Fatal Error (EEPROM or SRAM corrupted).

Solution

Measure voltage on pins 2 and 1 of the DB9 interface terminal

connnector. If voltage is out of specified range, then replace

power supply with a new one. If polarity is reversed (reading is

negative), make correct connection.

Return device to factory for repair.

Check J2 jumper configuration (see Table 9).

Check for external connections to pins 5 and 6 of the DB9

interface terminal connector. Make sure the loop resistance is

less than 400 Ohm for 12 VDC power supply option and 900

Ohm for 24 VDC power supply option.

Using Key Pad, navigate to submenu "Device Diagnostic" and

select submenu "Analog Output Value". Record the DAC counts

values and consult the factory with findings.

Check settings for Low Flow Cut-Off value and make required

adjustment (see Submenu "Low Flow Cut-Off").

Check J2 input jumper configuration (see Table 9). If necessary,

contact factory for additional help.

Using ESD precautions, measure voltage on pins 4 and 6 of the

DB9 interface terminal connector. If voltage correlates with flow

meter/controller output signal, check ADC counts. Using Key Pad,

navigate to Submenu "Device Diagnostic" and selet Submenu

"ADC Input Counts". Record the ADC counts values and consult

the factory with findings.

Check settings for "Totalizer #1 Flow Start" value and make

required adjustment (see Submenu "Totalizer #1 Flow Start").

Check settings for "Totalizer #1 Mode" parameter. Make sure

Totalizer Mode is set to "Enabled" (see Submenu "Totalizer #1

Mode").

Check settings for "Totalizer Power On Delay" (see Submenu

"Totalizer #1 Power On Delay"). If settings are too high, make

required adjustment.

Check J2 input jumper configuration (see Table 9). If necessary,

contact factory for additional help.

Check settings for "Full Scale Range" (see Submenu "Device

Calibration"). Full Scale Range parameter has to be set equal to

the mated device full scale flow rate in L/min.

Check settings for "Fluid Std. Density" (see Submenu "Device

Calibration"). This parameter is required only when mass-based

engineering units are selected.

Check J2 input jumper configuration (see Table 9). If necessary,

contact factory for additional help.

Check settings for "Full Scale Range" (see Submenu "Device

Calibration"). Full Scale Range parameter has to be set equal to

the mated device full scale flow rate in L/min.

Make sure interface type (RS-232 or RS-485) on the host PC is

the same as on the GFT2 device. Check communication wiring

connection according to "Digital Communication Interface

Connections".

Change GFT2 RS-485 address to match host PC software

settings.

Disconnect power from the GFT2. Make sure the ambient

temperature is within specified range (below 158°F or 70°C). Let

the device cool down for at least 15 minutes. Apply power to the

device and check Diagnostic Alarm Event. If overload connection

will be indicated again, the unit has to be returned to the factory

for repair.

Cycle the power on the GFT2. If System Event with code D

indicates again, the unit must be returned to the factory for repair.