KROHNE ALTOSONIC V Modbus EN User Manual

Page 46

ALTOSONIC V

ModBus Manual 0300 rev07 E

7.30855.35.00

Page 46 of 64

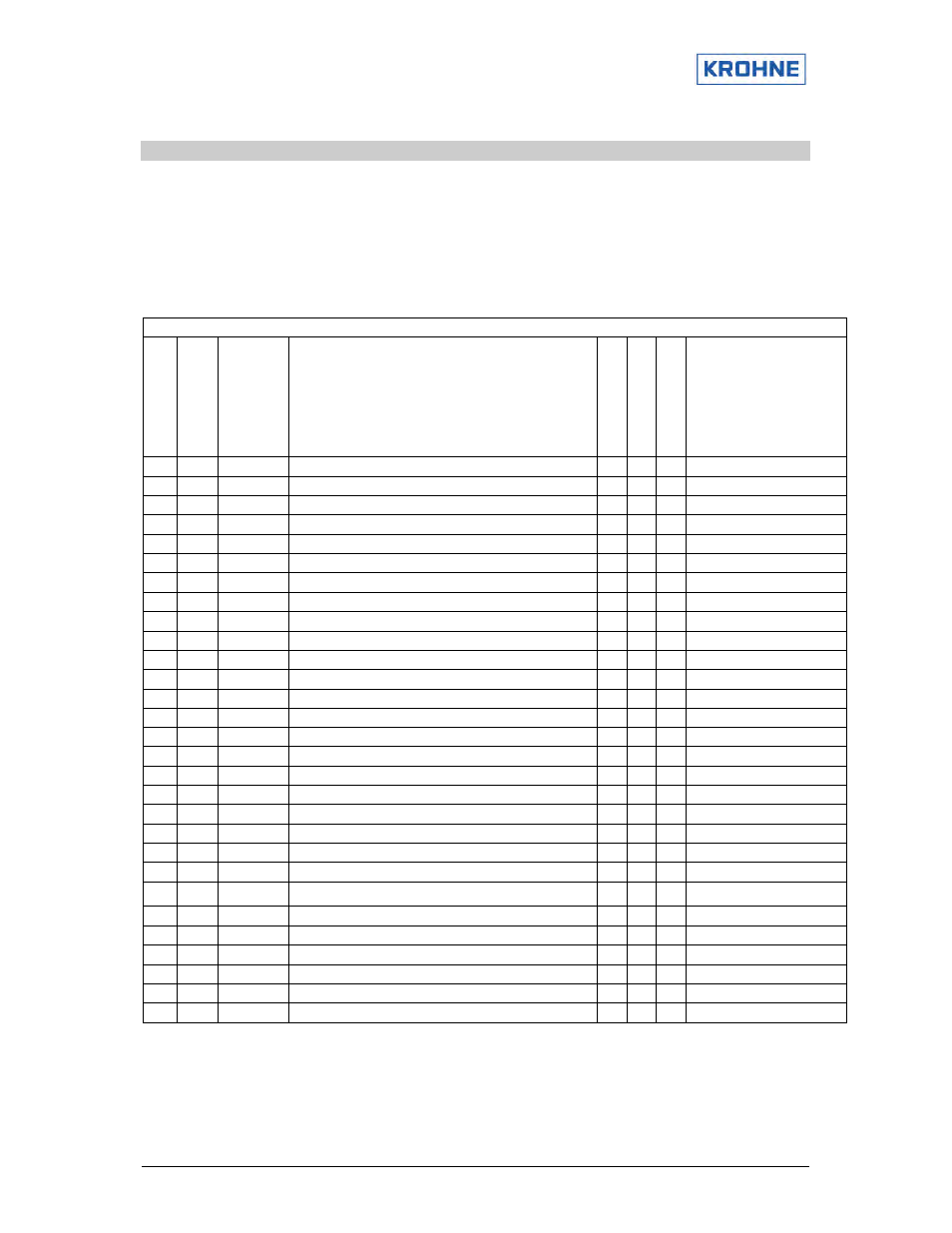

8.7

Field 6 (Read/Write Float Field)

In slave mode write to field by function 16, read from field by function 3.

In Master mode write to field by function 3, read from field by function 16

NOTE that for explanation on how to handle writing to these parameters:

see chapters

7.6 How data is written to the float field

8.10 Explanation of Data Available to Modbus

By default the start addresses are mapped to address 7500 (default value)

s

ta

rt

a

d

d

re

s

s

N

o

tM

o

d

ic

o

n

C

o

m

p

s

ta

rt

a

d

d

re

s

s

M

o

d

ic

o

n

C

o

m

p

T

y

p

e

+

A

c

c

e

s

s

D

e

s

c

ri

p

ti

o

n

Le

ve

l

Le

ve

l

Le

ve

l

R

e

m

a

rk

1

1

F32+R

API: time to update a parameter (read only)

5

s, max=30s

2

3

F32+RW

API: correction type

6

2

0,1,2

3

5

F32+RW

API: density standard type

6

2

0,1,2

4

7

F32+RW

API: fluid type

6

2

0,1,2,3,4,5

5

9

F32+RW

API: standard density crude (fluid type 0)

6

2

610.5..1075.0 kg/m3

6

11

F32+RW

API: standard density gasoline (fluid type 1)

6

2

653.0.. 770.0 kg/m3

7

13

F32+RW

API: standard density trans.area (fluid type 2)

6

2

770.5.. 787.5 kg/m3

8

15

F32+RW

API: standard density jet group (fluid type 3)

6

2

788.0.. 838.5 kg/m3

9

17

F32+RW

API: standard density fuel oil (fluid type 4)

6

2

839.0..1075.0 kg/m3

10

19

F32+RW

API: standard density free fill (fluid type 5)

6

2

500.0..2000.0 kg/m3

11

21

F32+RW

API: free fill K0

6

2

–10

e

9 .. 10

e

9

12

23

F32+RW

API: free fill K1

6

2

–10

e

9 .. 10

e

9

13

25

F32+RW

API: free fill K2

6

2

–10

e

9 .. 10

e

9

14

27

F32+RW

API: temperature standard

6

2

0-30°C

15

29

F32+RW

Standard correction selection

6

2

0,1,2,3

16

31

F32+RW

ASTM-IP standard density

6

2

600..1200 kg/m3

17

33

F32+RW

LPG/ULHC standard density

6

2

500..700 kg/m3

18

35

F32+RW

LPG equlibrium pressure / ULHC standard maximum error

6

2

0.00001..25

19

37

F32+RW

Reserved (Simulated flow. Only in dummy mode)

-125..125%

20

39

F32+RW

Reserved

21

41

F32+R

EXT: time to update a parameter (read only)

5

8

s, max 30 sec

22

43

F32+RW

EXT: external Kfactor

6

8

puls/liter

23

45

F32+RW

EXT/API: parameters changeable under flowing condition or < lfc

6

8

0=always, 1=only < low flow cut-

off

24

47

F32+RW

MeterFactor Positive Flow (if enabled in clnt0300.dat)

6

1

0.9..1.1

25

49

F32+RW

Meterfactor Negative Flow (if enabled in clnt0300.dat)

6

1

0.9..1.1

26

51

F32+RW

Reserved

27

53

F32+RW

Reserved

28

55

F32+RW

Reserved

29

57

F32+RW

Reserved