Commissioning / operation – KROHNE MFC 400 Profibus User Manual

Page 29

COMMISSIONING / OPERATION

4

29

MFC 400

www.krohne.com

06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

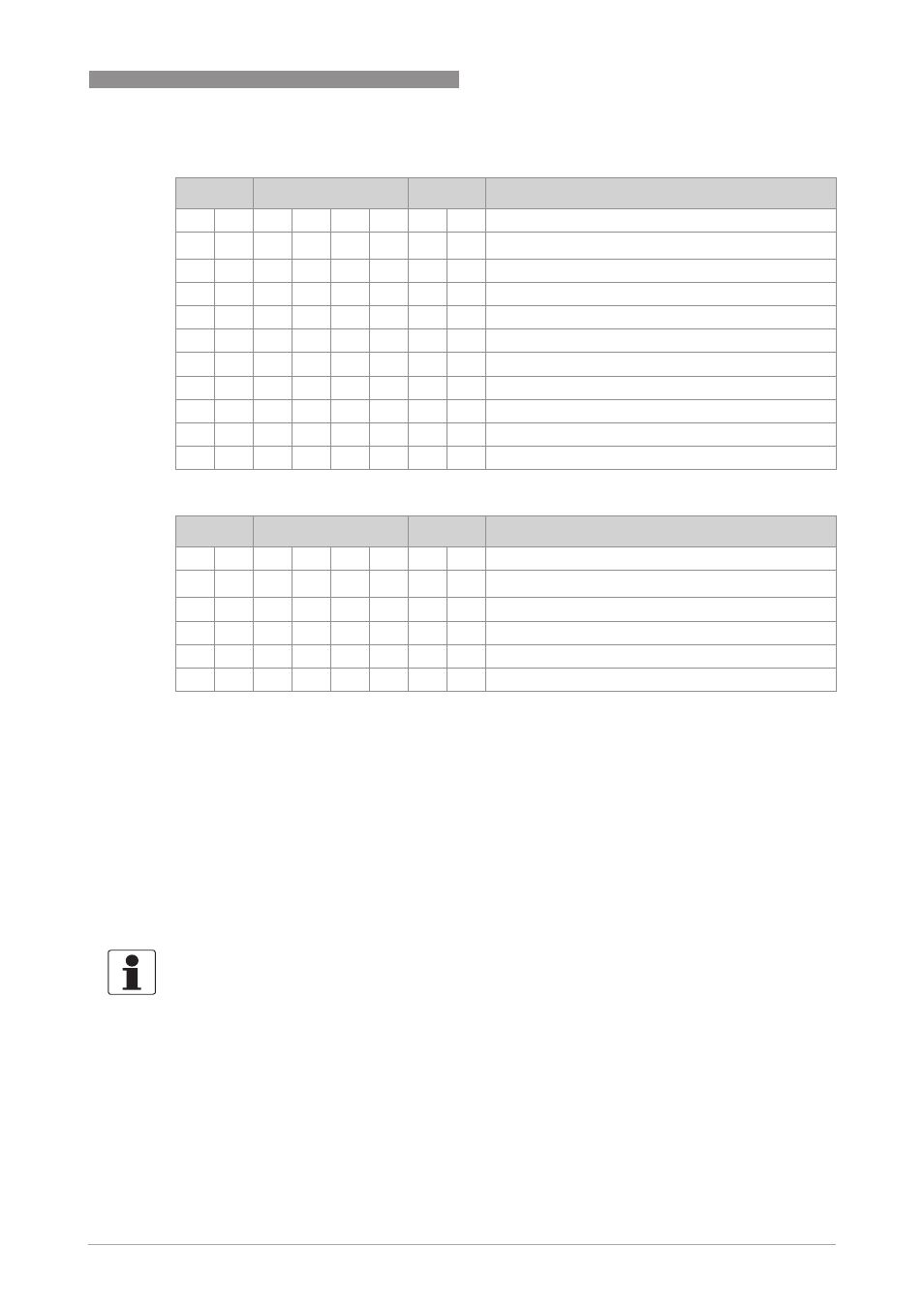

Status = good (Non Cascade)

Status = Limits

Check the first two quality bits in order to get the quality information of the measurement value:

• Good (Non Cascade):

Good (Non Cascade):

Good (Non Cascade):

Good (Non Cascade): function block output value is ok and can be used without restrictions

• Good (Cascade):

Good (Cascade):

Good (Cascade):

Good (Cascade): will not be supported, because it is not applicable for the device

• Uncertain:

Uncertain:

Uncertain:

Uncertain: function block output value can be used but the accuracy can not be guaranteed

(e.g. function block outputs value has been frozen or A/D converter is saturated or out of

range)

• Bad:

Bad:

Bad:

Bad: function block output value is bad - don’t use it for process control!

The "Quality-Substatus" and "Limit" bits will be used for further diagnostics or limit checking.

Quality

Quality substatus

Limits

Gr

Gr

QS

QS

QS

QS

Qu

Qu

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

1

0

0

0

0

0

= ok

1

0

0

0

0

1

= update event

1

0

0

0

1

0

= active advisory alarm

1

0

0

0

1

1

= active critcal alarm

1

0

0

1

0

0

= unacknowledged update event

1

0

0

1

0

1

= unacknowledged advisory alarm

1

0

0

1

1

0

= unacknowledged critical alarm

1

0

1

0

0

0

= initiate fail safe

1

0

1

0

0

1

= maintenance required

Quality

Quality substatus

Limits

Gr

Gr

QS

QS

QS

QS

Qu

Qu

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

0

0

= ok

0

1

= low limited

1

0

= high limited

1

1

= constant

INFORMATION!

The status should be monitored because a number will be transmitted even if the status of the

measurement value is bad or uncertain. This is the only way to check the quality of the

transmitted measurement values.