Operation – KROHNE OPTISYS SLM 2100 EN User Manual

Page 60

5

OPERATION

60

OPTISYS SLM 2100

www.krohne.com

03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

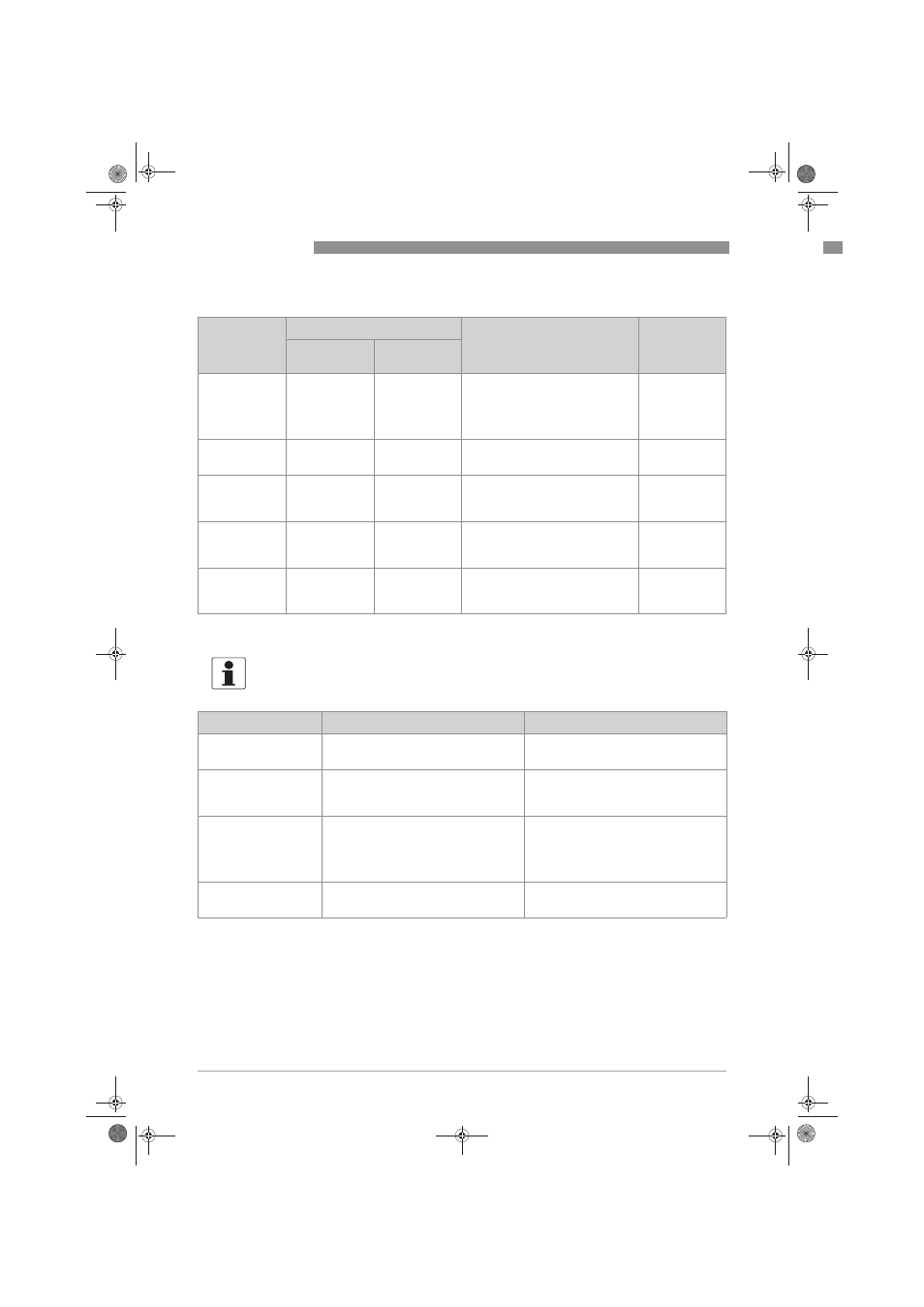

Explanation of the error categories

5.8.1 Error category "Device failure" (bold "F")

Letter on display Error category according to:

Description

Action

NE64

VDI/VDE 2650

and NE107

Bold "F

F

F

F"

Failure

Device failure

Whole device or single component(s)

defective, replacement necessary,

measured values are not valid; mA

output ≤ 3.6 mA or set fault current

(depending on the seriousness of the

fault).

Repair or

replacement

necessary!

F (not bold)

-

Application

failure

No internal error, but application

error has occurred; device okay, but

measurement not possible.

Application test

or operator action

necessary!

S

-

Out of

specification

Measurement out of specification;

measurement continues, but

measured values only restrictedly

usable.

Maintenance and

an accurate

check required!

C

Check request

Passivated

Either the device is outside operation

(standby, measured value is fixed or

specified), or the output values are

partially simulated or fixed.

Maintenance

required.

I

-

-

Information, current measurement is

okay and values unrestrictedly valid.

Depends on error

message, see

table in relevant

section.

INFORMATION!

Regard that in case of an error message of the category "F

FF

F" the measured values are not valid!

Messages on the display Description

Actions

F

F

F

F motor blocked

The motor has been blocked three times.

Check if sensor and cable can be freely

moved, if so reset error manually and

restart measuring cycle.

F

F

F

F sensor comm error

Communication to sensor is permanently

interrupted.

Check if pick up axle board is correctly

seated and the optical path is clean. Error

needs to be reset manually and

measurement can be started again.

F

F

F

F limit switch error

Indicating a failure of the sensor limit

switch.

Check if the sensor can move up and down

by using the manual mode. If the sensor

does not reel down open the cable drum

compartment and look if the cable is reeled

up correctly. If the sensor is blocked, try to

pull it down carefully.

F

F

F

F sensor calibration

Zero calibration was performed with higher

turbidity than used for the calibration of the

concentration.

Repeat calibration in correct order again

.book Page 60 Wednesday, April 30, 2014 1:39 PM