Rl5000 – Triton RL5000XP PC-BASED ATMS Installation Manual User Manual

Page 32

32

RL5000

XP

I

NsTaLLaTION

G

UIDE

MARK/DRILL

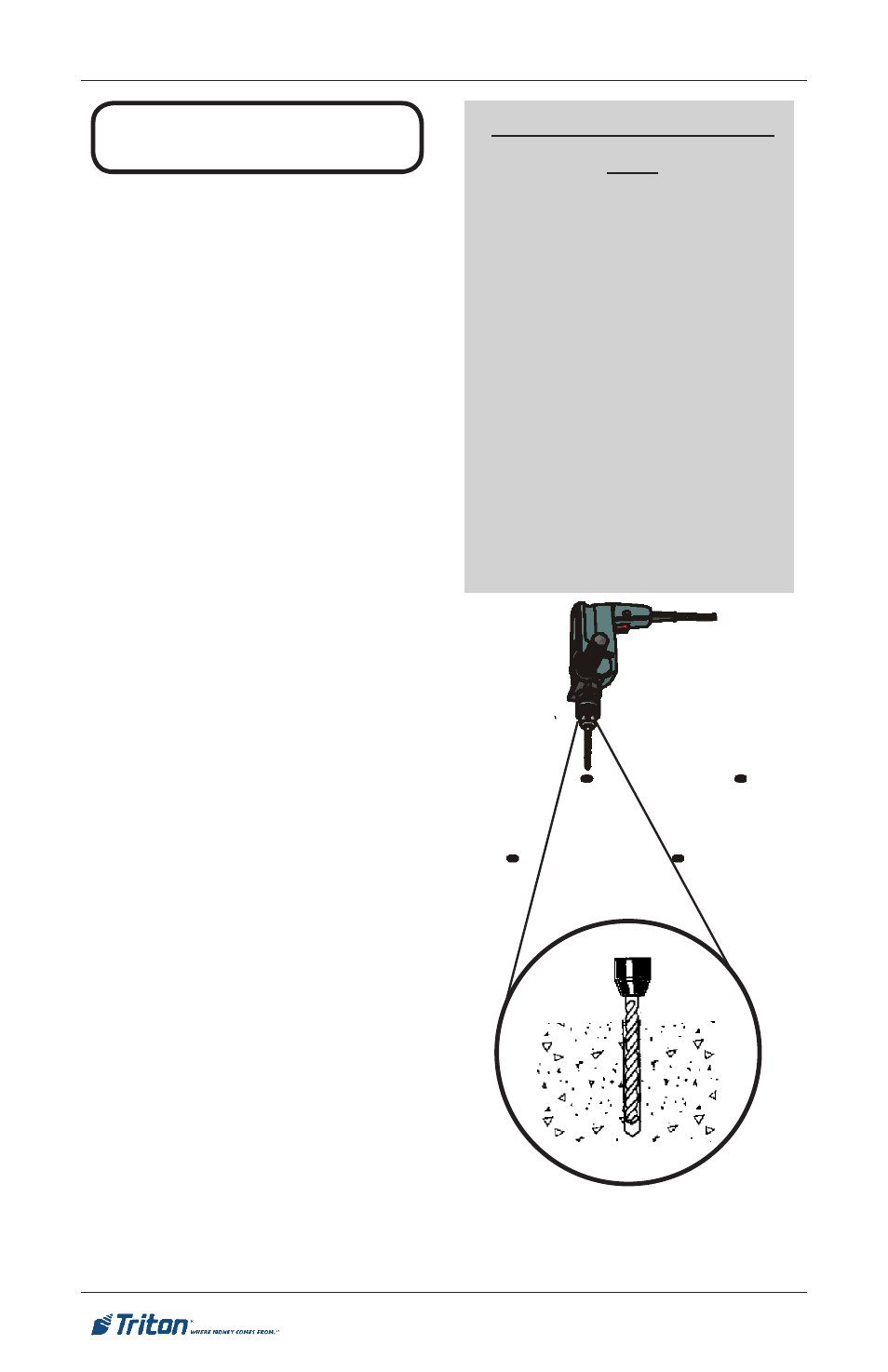

MOUNTING HOLES

Mark the location of the cabinet

mounting holes on the concrete floor.

This is accomplished as described

below:

1. Move the ATM to the location

where it will be installed.

Open the cabinet door at least

90° degrees to improve access.

Locate the four anchor-bolt holes

(cutouts) in the bottom of the

cabinet. Use a felt-tip pen or

other marker to carefully mark

the center of each of these four

holes on the floor; these marks

will serve as guides for the anchor

bolt holes that will be drilled in

the next step.

Move the ATM aside, to provide

clear access to the mounting hole

marks.

Fig. 1. Drilling mounting holes.

2. Use a 6 mm (1/4”) diameter

carbide-tipped masonry bit

to drill four pilot holes at the

drilling points marked in the

previous step. Drill the pilot holes

approximately 12 mm (1/2”)

deep into the floor. These holes

will help guide the 1/2” masonry

bit that will be used to drill the

anchor-bolt holes in the next step.

CHEMICAL ANCHOR SYS-

TEM

The chemical anchor installation

system used in this procedure

bonds threaded anchor-rod inserts

to the base material (for ATM

applications this is typically a

concrete foundation). Unlike tra-

ditional expansion-bolt anchoring

systems, chemical anchoring is

accomplished without exerting

expansion forces against the base

material. As a result, the chemical

anchoring system proves ideal for

anchoring in a wider selection of

materials from brick to granite.