Air cylinder shifter assembly, Blocked clutch – Ramsey Winch RPH-8000 User Manual

Page 11

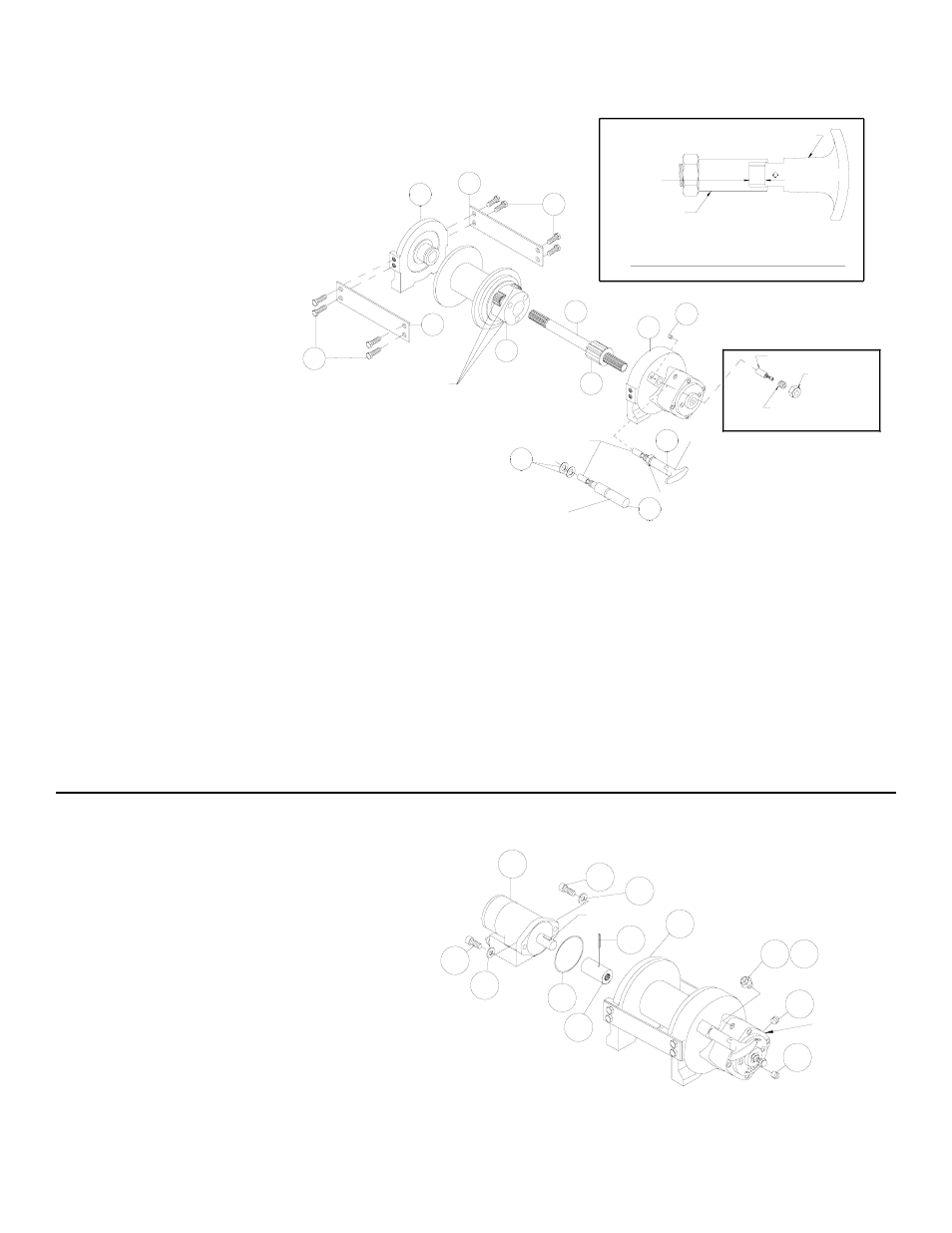

If necessary, remove and replace the shifter assembly (manual, item #2, or air-cylinder, item #3), as follows:

MANUAL CLUTCH SHIFTER ASSEMBLY

Remove by loosening setscrew (item

#25), jam nut and unscrewing clutch

shifter. Be sure slot in ring gear is not

aligned with clutch shifter hole.

Rotate drum, if necessary, to insure

hole and slot are not aligned. Re-install

clutch shifter with plunger, jam nut and

handle positioned in cylinder housing,

as shown. Thread assembly (with

handle engaged in cylinder slot) into

the end bearing. Pull drum toward the

brake housing end bearing to remove

play.

Hold drum in the position and continue

threading the shifter assembly in until

the gap between the end of the handle

and cylinder is 7/16 +0 -1/18 inch

and handle is in the horizontal posi-

tion, as shown below. NOTE: This gap

will vary with drum endplay. With the

drum pulled against the gear housing,

the gap should be 7/16 inch. Lightly

tighten jam nut.

Rotate drum until handle snaps fully into the engaged position. Pull handle out and rotate 90º. Verify that drum can be rotated freely (at least

one full revolution) with clutch shifter at DISENGAGED position. Securely tighten jam nut while holding the handle.

Tighten setscrew securely. Re-check clutch operation as described on Page 5.

AIR CYLINDER SHIFTER ASSEMBLY

Remove by loosening setscrew (item #25), jam nut and unscrewing clutch shifter. To reinstall, thread air cylinder into housing. Install one or

two shims (item #49) under cylinder head, if needed, to orient air cylinder port for pneumatic connections. Tighten setscrew. Refer to Page

5 and check for proper operation of the clutch.

BLOCKED CLUTCH

Insert plunger assembly into gear housing bore so it engages into ring gear slot. Pull drum flange toward gear housing and thread setscrew

into housing until it bottoms out and drum starts to move. Back setscrew out 1/2 turn and lock in place with jam nut.

Before installing motor, check brake adjustment (refer to Page 7, ADJUSTING THE BRAKE).

Place splined end of coupling (item #31), with spirol pin (item

#41) installed, inside of motor end bearing housing (item #7)

and slide over splines on end of input shaft. Place o-ring (item

#38) around motor pilot. Mount motor (item #35) to end

bearing by aligning key on motor shaft with keyway in cou-

pling. Be sure that motor mounts flush to end bearing and that

o-ring is set securely in place between motor and end bearing.

Secure motor to end bearing using two capscrews and lock-

washers (items #24 & #30). Tighten capscrews to 49 ft-lbs.

(66 Nm.). Thread plug (item #40) into bottom of brake hous-

ing. Permatex can be added to threads of plug to help in seal-

ing.

Pour mixture of 1/2 pint (8 ounces) of Mobilfluid 424, Phillips

HG Fluid, Texaco TDH, Shell Oil Company Donax TD high per-

formance tractor transmission fluid, or equivalent, and 1/4 ounce of an oil additive (available from the factory) into oil level hole. Oil level

should be kept at oil level hole (plus or minus 1/8"). Thread plug (item #40) into oil level hole. Insert reducer (item 339) into hole in top of

brake housing and breather plug (item #34) into reducer. Tighten plugs and reducer securely.

11

5

8

7

13

12

18

7/16

-1/16

+0

13

1

CLUTCH SHIFTER

AIR-CYLINDER

PLANET GEARS

PLUNGER

49

3

MANUAL CLUTCH

JAM NUT

2

SHIFTER

MANUAL CLUTCH ADJUSTMENT

HANDLE (HORIZONTAL)

CYLINDER

25

PLUNGER ASSEMBLY

JAM NUT

SETSCREW

BLOCKED CLUTCH

18

OIL LEVEL

40

39

35

24

KEY

7

30

24

31

38

30

41

HOLE

40

34