Ramsey Winch RPH-8000 User Manual

Page 10

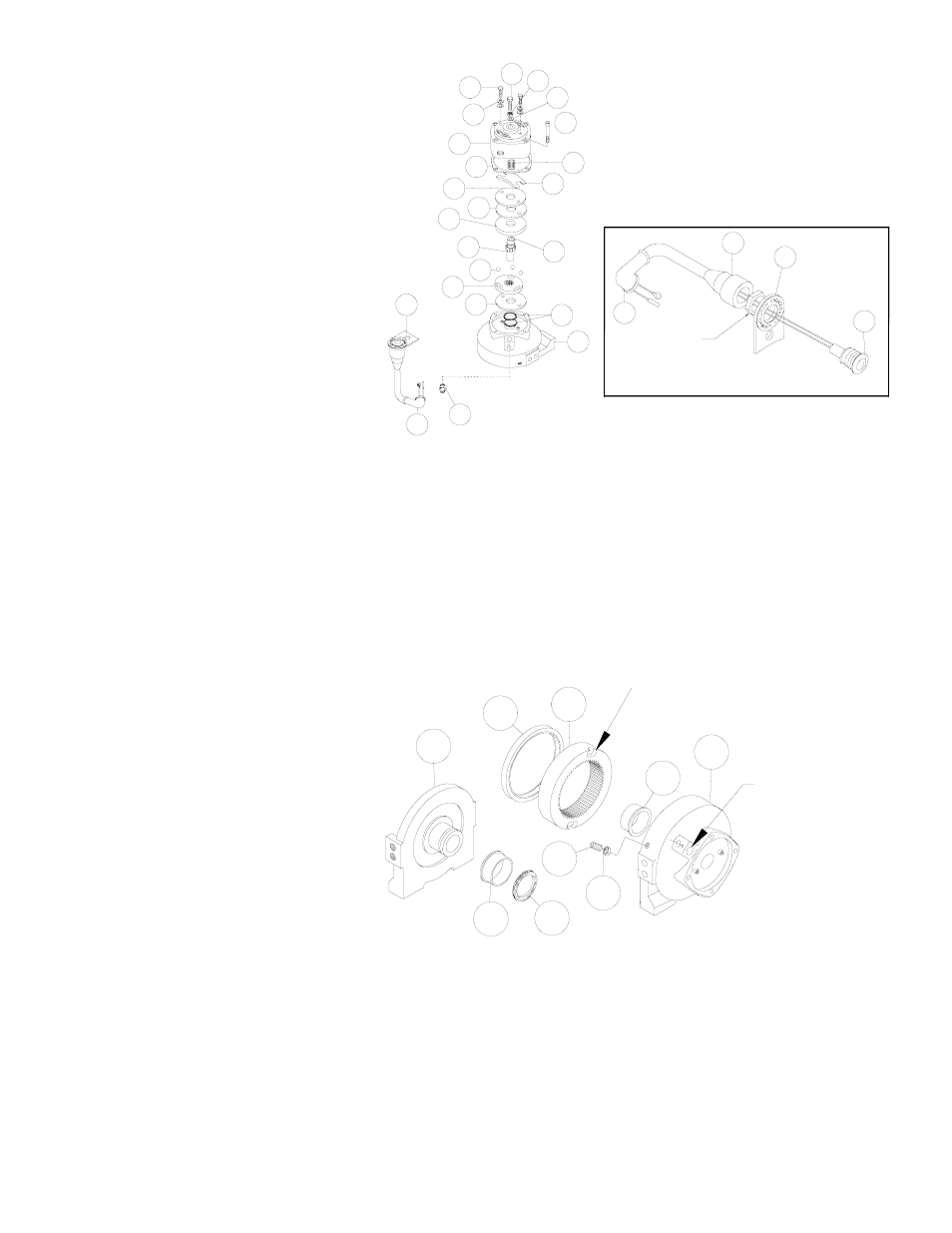

Remove brake housing (item #9) from end bear-

ing (item #8) by unscrewing (4) capscrews

(item #23). Remove plate (item #12) and light

assembly, if present. Remove gasket (item #33),

coil spring (item #48), flat spring (item 3),

retainer plate (item #11), composition brake

discs (item #32) and cam plate (item #4).

Remove hub (item #10) with plug (item #42) –

which is press-fitted in the hub I.D. (Inside

Diameter). Inspect the seal (item #37), inside of

gear housing bore, and replace if necessary.

Inspect brake discs. Discs are 1/4" thick when

new, replace if thinner than .200 inch thick or if

surfaces are glazed or burnt. Inspect the flat

ground surfaces of the cam plate and retainer

plate for glazing, warpage or other damage.

Glazing can be removed by scraping carefully.

Inspect flat spring. It should be bowed at least

1/8". Replace spring if bowed less than 1/8".

Replace all worm or damaged parts as needed. Re-assemble all parts as shown. Be sure balls are secure between cam plate

and hub.

Install brake housing, making sure that ends of capscrews (item #17) go through notches in end of flat springs and holes in the

retainer plate. Secure brake housing and plate (item #12), if present, to end bearing using capscrews (item #23). Tighten cap-

screws to 30-40 ft-lbs.

INDICATOR LIGHT ASSEMBLY

If light is not functioning, remove light (item #2) and apply 12V DC (+) to test. If necessary, remove the switch (item #52).

The terminals are normally closed. With ball depressed, the switch should be open. Replace light and/or switch, as needed.

Remove o-ring (item #36) and bushing (item

#15) from motor end bearing (item #7). Press

new bushing onto end bearing and dip o-ring in

oil and seat into groove of end bearing. Remove

seal (item #45) from gear housing end bearing

(item #8). Loosen nut (item #27) and remove

nylon setscrew (item #22) and remove ring

gear (item #6) from gear housing end bearing,

if necessary. Remove bushing (item #16) from

gear housing end bearing (item #8). Press new

bushing (item #16) into place in end bearing.

Install ring gear and nylon setscrew and nut.

Ring gear must be fully seated in gear housing

end bearing (item #8) and slot in ring gear

must NOT be aligned with clutch shifter hole. Install new seal in gear housing end bearing, with sharp edge of seal outward.

Generously apply grease (MOBILITH SHC 007) to teeth of ring gear (item #6), teeth of planet gears in drum (item #1) and to

bushing in end bearings (items #7 & #8). Apply grease to teeth of gear (item #5) and to splines of shaft (item #12). Place

splined end of shaft into splines of hub in brake housing end bearing (item #8). Place drum over shaft and rotate drum to

engage planet gears with output gear on shaft and ring gear in end bearing.

Assemble end bearing to drum assembly and use tie plates (item #13) and capscrews (item #18) to hold both end bearings

together. Tighten capscrews to 55 ft-lbs. (75 Nm.).

12

52

45

32

14

32

10

4

33

9

11

29

17

19

37

42

8

23

48

3

28

44

51

2

12

NUT

CLUTCH ENGAGEMENT INDICATOR

LIGHT ASSEMBLY

45

46

27

SLOT IN RING GEAR

6

22

15

36

7

45

8

SHIFTER HOLE

CLUTCH

16

10