2 modbus support, Modbus™ register allocations, 2 modbus – Ronan X76CTM User Manual

Page 21: Support

20

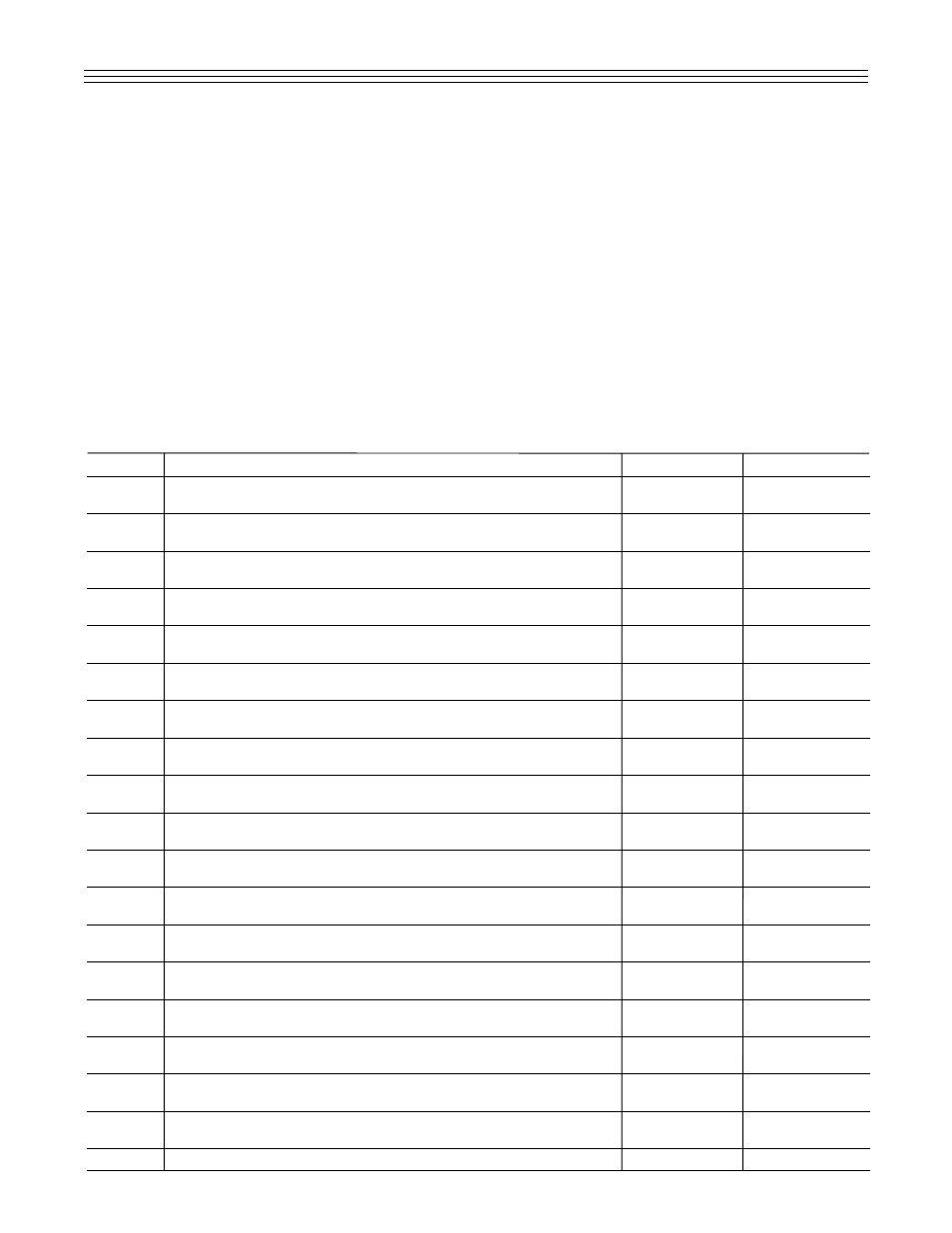

Register

Parameter Name

Dimension

Data Style

1

Product Level.

Inches

Floating Point

2

3

Water Level.

Inches

Floating Point

4

5

Product Gross Volume.

Gallons

Floating Point

6

7

Total Gross Volume.

Gallons

Floating Point

8

9

Product Average Temperature. The average of the submerged

°F

Floating Point

10

thermistor temperature.

11

Product Net Volume. The volume calculated when the product

Gallons

Floating Point

12

temperature is 60°F.

13

Current CSLD (Continuous Statistical Leak Detection) Leak Rate.

Gallons

Floating Point

14

Rate is based on at least one month test history.

per Hour

15

Last Completed Leak Test Rate. A test that has not been canceled

Gallons

Floating Point

16

before the scheduled test duration has expired.

Per Hour

17

Time of Last Completed Test. Time is in UNIX format (32 bit

Seconds

Unsigned Long

18

integer, number of seconds since January 1, 1970).

Number

19

Tank Status. A field with different flags that correspond to tank

Unsigned Long

20

alarms.

Number

21

Scaled Product Level.

0.001 Inches

Unsigned Long

22

Number

23

Scaled Water Level.

0.001 Inches

Unsigned Long

24

Number

25

Scaled Product Gross Volume.

0.001 Gallons

Unsigned Long

26

Number

27

Scaled Total Gross Volume.

0.001

Unsigned Long

28

Number

29

Scaled Product Average Temperature. The average of the sub-

0.001°F

Unsigned Long

30

merged thermistor temperatures.

Number

31

Scaled Product Net Volume. The calculated volume when the

0.001 Gallons

Unsigned Long

32

product temperature is 60°F.

Number

33

Scaled Current CSLD (Continuous Statistical Leak Detection)

0.001 Gallons

Unsigned Long

34

Leak Rate. Based on a least one month test history.

per Hour

Number

35

Scaled Last Completed Leak Test Rate. A test that has not been

0.001 Gallons

Unsigned Long

36

canceled before the scheduled test duration expired.

per Hour

Number

37-50

Reserved.

Modbus™ Register Allocations

trator can access and alter the user codes.

Function 62 is used to change the PIN codes.

During new code entry, the numbers are sub-

stituted with asterisks (*) on the display for

additional security. The administrator should

first log in, then enter the new user number.

This starts the login procedure for the new

user. When Function 62 is pressed, a prompt

for entering the user’s PIN will appear.

For example: To change the PIN for user 4,

log in as administrator, pressing 0. Enter the

PIN code for administrator. The default dis-

play will appear. Press 4. The X76CTM will

prompt to enter the user 4 PIN number. Dis-

regard prompt and press Function 62. The

system will prompt again for the new user 4

PIN number. Enter the new code.

10.2 Modbus

™

Support

The X76CTM supports Modbus™ protocol in

both ASCII and RTU modes. The mode is

selectable via the front panel or the text ter-

minal interface. For constant reading of the

tank information, the RTU mode is recom-

mended because of the small data overhead.

10.2.1 Register Allocation.

The system data

accessible through Modbus™, is on a per

tank basis.The variables are sent in IEEE

4 bit floating point format or as 4 bit scaled

integer long numbers, for devices that do not