Teledyne LGA-3500 - Laser Gas Analysis system User Manual

Page 28

Installation Model

3500

Teledyne Analytical Instruments

14

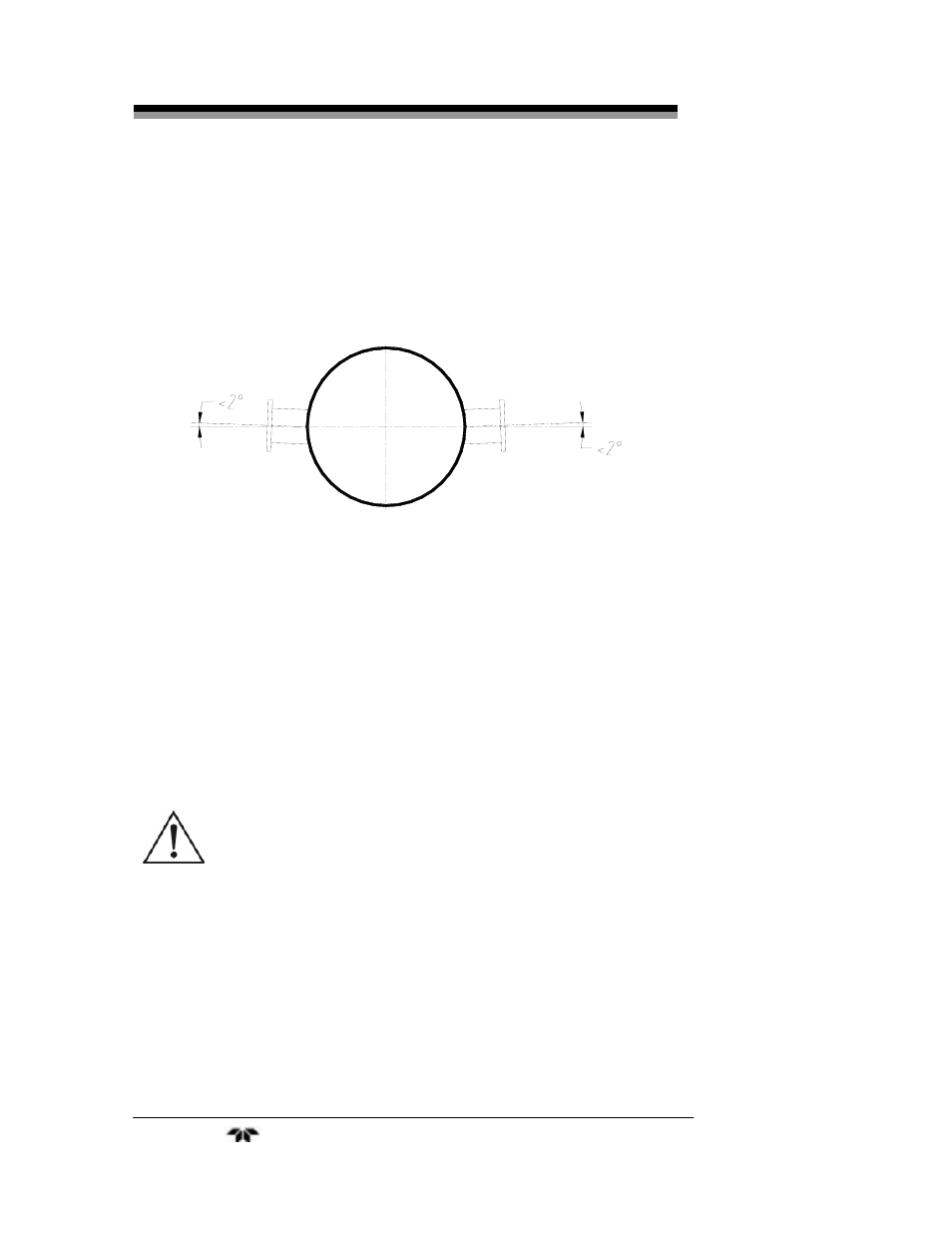

to have a limited coaxial offset between them. When welding the two

welding flanges the offset angle between their axes must be held to less

than 4°. Typically, the two welded flanges are positioned horizontally on

the gas flow pipe well across the pipe diameter As Shown in Figure 3-2.

Figure 3.2: Allowed offset for welded flanges

3.3.2 Installing Instrument Flanges

After welding the flanges, the Model 3500 probes can be installed.

Before installing, apply a lubricant to all the screw connections. To

make adjustments easier it is suggested that you use the adjusting aid

tools available from TAI

(P/N XXXXX)

. These include a visible light

laser pen and a scaled target for alignment.

WARNING: POWER TO THE SYSTEM MUST BE OFF DURING

THE INSTALLATION OF THE TRANSMITTER AND

RECEIVER UNITS. DO NOT CONNECT OR SWITCH

ON THE POWER SUPPLY AT THIS STAGE. THE

LASER BEAM IS INVISIBLE AND CAN CAUSE EYE

DAMAGE.

Mount the two instrument flanges onto the welded welding flanges

with 8 M16 bolts (with spring washer and plain washer) and 2 O-rings.

Raise the instrument flanges to the same height as the welded flanges,

then tighten the 8 M16 bolts to about half tight to make sure that the O-

rings are sealing. Typically the distance between the instrument flange

and the welding flange is around 3mm. See Figure 3.3.