Alamo Machete T 7740 User Manual

Page 49

© 2005 Alamo Group Inc.

1-43

MACHETE

TECHNICAL INFORMATION BULLETIN No. 101802

Alamo Industrial ™ Technical Services Department

1502 East Walnut

Seguin, Texas 78155

830-372-2708

Models:

All Machete, A-Boom, Versa, Rear Mount, Slopemower,

Brahma, EKII, Hydro 60, Hydro 72 & Hydro 15

All Hydraulic powered Rotary Mower heads that utilize the

# 02960553B, 02960553C and 02968859A Spindle Assemblies.

Date:

Oct. 18, 2002

Bulletin No:

101802

This document does not authorize the repair or replacement of parts under warranty

Spindle Bearing Lubrication Update:

Normal maintenance of the # 02960553B, 02960553C and 02968859A Spindle assemblies

has included the addition of NLGI 000 grease to provide proper lubrication of the bearing assemblies.

Due to repeated customer requests, this lubrication requirement has been changed to NLGI EP, #

2 Lithium Wheel Bearing Grease.

Implementation of this grease will allow

improved lubrication especially to the top bearing

as well as substantial improvement of the daily

maintenance requirements.

Conversion:

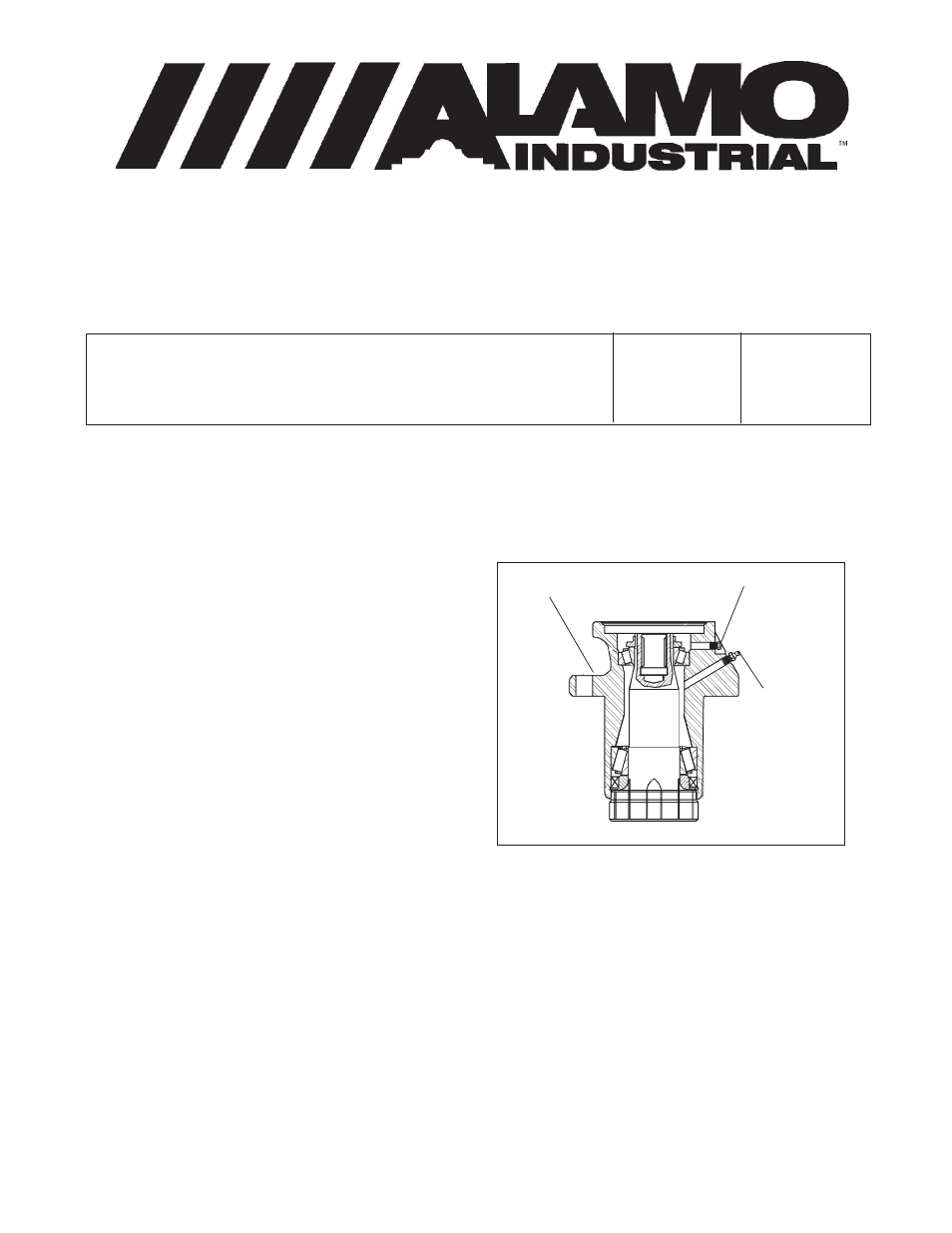

1.

Remove the existing fill plug from the

spindle housing and discard it. (this is the

lower plug in figure 1)

2.

Install a standard 1/4" fine thread grease

zert into the fill plug port as shown in figure 1.

3.

Remove the Vent plug (Top plug in figure 1)

4.

Fill the housing with NLGI EP, # 2 Lithium Grease or equivalent from a standard grease gun

until the new grease is seen in the vent plug hole. (Approximately 2 standard grease tubes

will be required when Spindle Assembly is empty).

5.

Clean off any excess or over flow grease and reinstall vent plug.

6.

Maintain proper lubrication with 5 pumps of grease into the spindle every 8 hours of use. This

will keep the Spindle bearings lubricated.

7.

Always clean excess Grease away from Spindle after greasing Spindle.

Grease

Zert

(added)

Vent

Plug

Spindle Assembly

Figure 1