GF Signet 2714-2717 pH_ORP Electrodes User Manual

Page 4

Technical Features

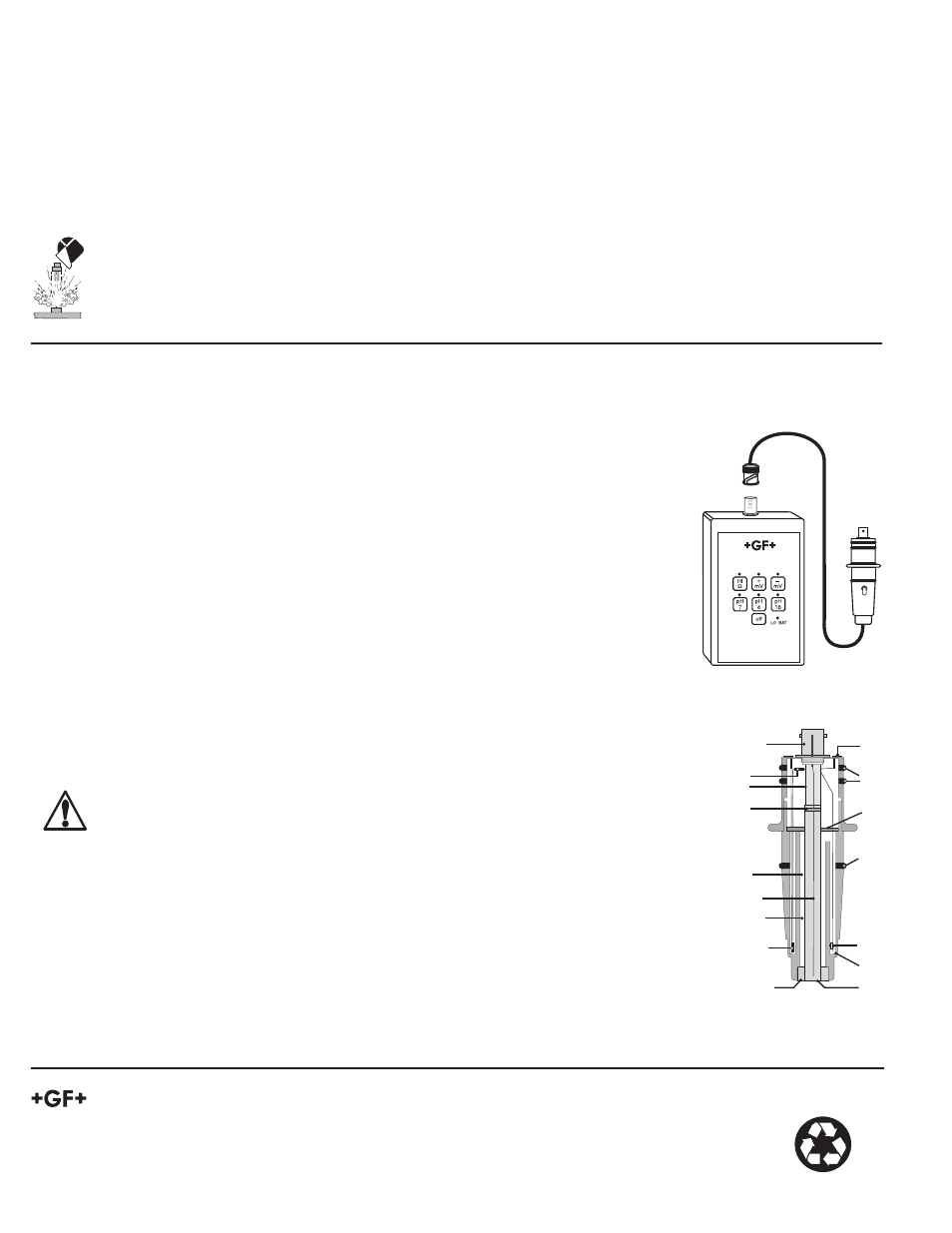

a) Male BNC connector

b) Keyed for a simple sure fi t

c) Viton® O-rings

d) Silicone-bushing seal

e) Double junction

f) Ag/AgCl reference element

g) Platinum sensing surface (ORP) or fl at pH glass

h) Porous UHMW polyethylene reference junction

a

b

c

d

e

f

g

o

l

k

j

i

h

n

m

c

Georg Fischer Signet LLC, 3401 Aerojet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

3-2714.090-1 J 3/08 English

© Georg Fischer Signet LLC. 2008

Printed in U.S.A. on recycled paper

6. Replacement parts and accessories

Mfr. Part No.

Code

Description

3-2714

198 844 300

Flat pH Electrode

3-2714-HF

198 844 305

Flat pH Electrode, HF Resistsant

3-2715

198 844 301

Flat ORP Electrode

3-2716

198 844 302

Bulb pH Electrode

3-2716-DI

198 844 306

Bulb pH Electrode, DI Resistant

3-2717

198 844 303

Bulb ORP Electrode

3-2759

159

000

762

pH/ORP

Simulator/System

Tester

3-2759.393

159 000 765

Adapter Cable for use with 2720

3-2720

198 864 602

Preamplifi er, ¾ in. NPT

3-2720-2

198 864 603

Preamplifi er, ISO 7-R ¾

P31515-0P200

159 000 630

PVC Pipe Adapter

P31515-0C200

159 000 631

CPVC Pipe Adapter

P31515-0V200

159 000 459

PVDF Pipe Adapter

3-0700.390

198 864 403

pH Buffer Kit

1220-0021

198 801 186

O-ring, FPM (standard)

1224-0021

198 820 006

O-ring, EPDM

1228-0021

198 820 007

O-ring, Kalrez

i) 3K Balco thermistor

j) Solidifi ed acrylamide reference

electrolyte

k) Ag/AgCl measuring element

l) Large reference volume

m)

Epoxy seal

n) Shielding

o) 10K

Ω I.D. resistor for ORP sensor

CAUTION!

Apply O-ring lubricant to sensor O-rings prior to assembly.

Unlubricated O-rings may score the sealing surface in the 2720.

WARNING!

Wear appropriate eye, face, hand, body, and respiratory protection when using chemicals or solvents.

pH

ORP

Signet

MODEL 2759

pH/ORP SIMULATOR

3-2759 pH/ORP

Simulator/System Tester

5.2 Cleaning

Cleaning techniques vary depending on the type of coating present on the glass electrode surface or reference junction.

• Soft coatings can be removed by vigorous stirring, or with directed spray of an applicable detergent or solvent onto the glass

electrode surface. Chlorine bleach or mild detergent may be used to remove soft coatings. Always rinse electrode tip in clean water

after cleaning.

• Hard coatings can be chemically removed. Use the least harsh chemical which will remove the contaminant within two (2) minutes

without attacking the materials of construction. e.g. calcium carbonate may be removed with a 5% HCl (muriatic acid) solution.

• Oily or organic coatings can be removed with detergents or an appropriate solvent that does not attack the materials of

construction e.g. isopropyl alcohol may be used but acetone must be avoided to prevent damage to the CPVC sensor body.

• ORP electrode surface (platinum rod) can be gently sanded with 600 grit wet and dry silicone or carbide sandpaper, jewelers rouge,

crocus cloth, or very fi ne steel wool.