Caution, 0 _installation – Brooks Instrument XacTorr CMX160 User Manual

Page 25

p.19

3.0 INSTALLATION

3.1 CMX MOUNTING CONSIDERATIONS

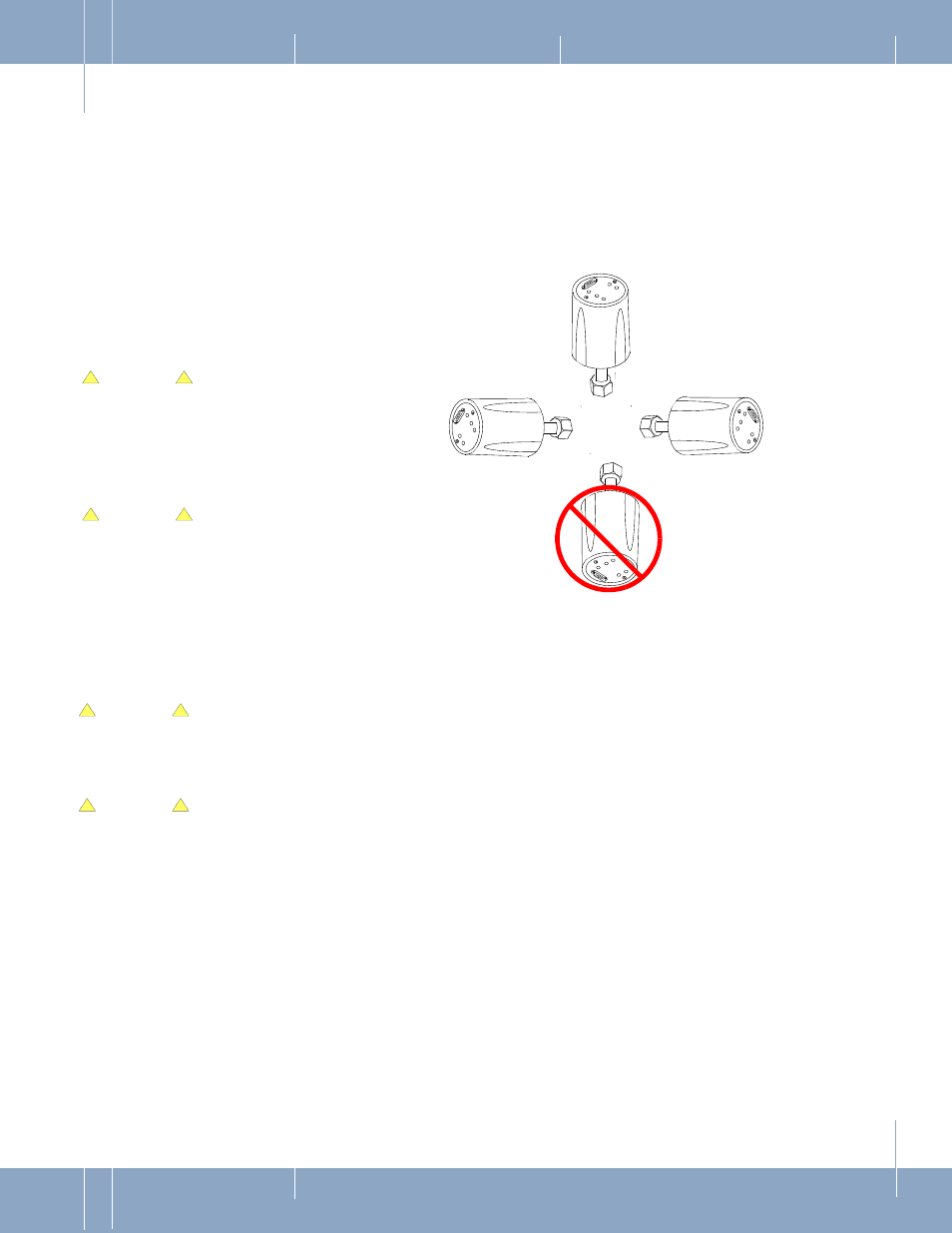

Figure 19: Mounting Orientation

3.2 PLUMBING SIZE

When connecting any CMX to the system chamber, minimize restrictions

between the CMX and chamber to maximize the conductance. This is important

to maintain the response characteristics of the CMX in a dynamic control

system. The following should be considered:

• Tubing Size Diameter

• Tubing Length

3.3 USE OF AN ISOLATION VALVE

The use of an isolation valve will reduce the need to wait for the device to

re-stabilize after each vent to atmosphere. Although not required to protect the

CMX, it is strongly recommended that you use an isolation valve for all CMX with

one Torr and below full scale range.

3.4 MATERIAL EXPOSURE

The process gas needs to be compatible with Inconel and/or 316L stainless

steel. If the process generates by-products that could deposit inside the CMX, a

heated device should be used to reduce this deposition.

A

b

cd

ef

g

NO

A

b

cd

ef

g

Ab

cd

efg

Ab

cde

fg

CAUTION

!

!

Minimize vibration around the

CMX to eliminate output electri-

cal noise and provide a longer

instrument life. Mount the CMX

away from direct sunlight, heat-

ing/cooling system ducts, gas

vents, and other sources of

temperature variation.

CAUTION

!

!

For an CMX with full scale 01

Torr or less, the mounting ori-

entation for the device is speci-

fied for optimal performance.

Horizontal mounting should be

used unless there is a “V” (ver-

tical mounting) in the model

number.

CAUTION

!

!

The tubing between the CMX

and the system chamber must

be of equal or greater internal

diameter than the CMX inlet

tube.

CAUTION

!

!

The tubing between the CMX

and the system chamber must

be as short as possible, with

the maximum length no longer

than 152 mm [6”].

3.0

_INSTALLATION