Brooks – Brooks Instrument GF81 User Manual

Page 45

4-7

Brooks

®

GF40/GF80/GF81 Devices

Installation and Operation Manual

X-TMF-GF40-GF80-Series-MFC-eng

Part Number: 541B161AAG

June, 2013

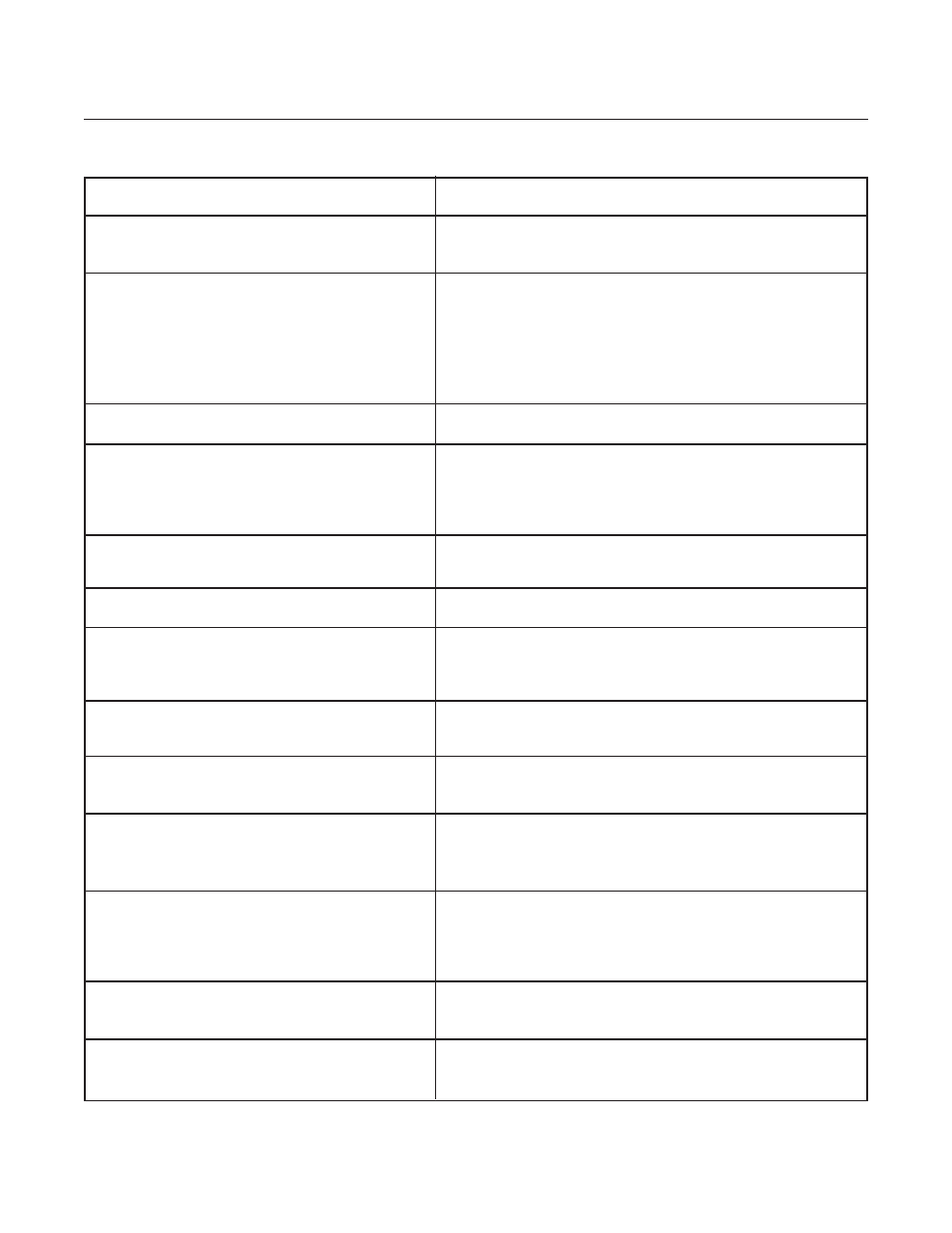

Section 4 Maintenance & Troubleshooting

Symptoms & Possible Causes

Corrective Action

7. OEM tool does not read correct

GF40/GF80/GF81

Series zero reading.

Is the differential pressure across the

GF40/GF80/GF81

Series valve leakage.

GF40/GF80/GF81

Series really zero?

Incorrect MFC zero.

Is the supply voltage within specified range?

Is the

GF40/GF80/GF81

Series mounted in the proper

attitude? Is the flow output signal of the

GF40/GF80/GF81

Series really zero?

8. Zero Drift.

Improper zero of the

GF40/GF80/GF81

Series?

GF40/GF80/GF81

Series aging or sensor stabilization.

Excessive Valve leakage?

Zero is not correct.

9. Calibration Drift.

Gas box temperature too high?

Zero is not correct.

Is it linear offset?

10.

GF40/GF80

Series indicates Overshoot.

If the tool is idle for an extended period of time,

Purge the line before operating.

high inlet pressure or contamination will cause

overshoot on first use.

11.OEM tool indicates the wrong full scale

value for

GF40/GF80

Series.

Older version of Multiflo Configurator used

Update Multiflo Configurator.

Refer to Section 2-17.

to program

GF40/GF80

Series.

12.

GF40/GF80/GF81

Series dumps large

volume of gas into chamber when setpoint is

commanded from the tool.

The tool is commanding a setpoint before the

Change the tool sequence.

pneumatic valves are opened.

GF40/GF80/GF81

Series and pneumatic timing may

be offset.

GF40/GF80/GF81

Series overshoots.

13. Tool display output doesn’t match

GF40/GF80/GF81

Series flow output.

Cable resistance or read-out impedance causing

Check cables and read out. Eliminate any ground loops.

offset in the tool’s display.

Table 4-2 GF40/GF80/GF81 Series Troubleshooting Guide (Continued)