Brooks – Brooks Instrument GF81 User Manual

Page 44

4-6

Brooks

®

GF40/GF80/GF81 Devices

Installation and Operation Manual

X-TMF-GF40-GF80-Series-MFC-eng

Part Number: 541B161AAG

June, 2013

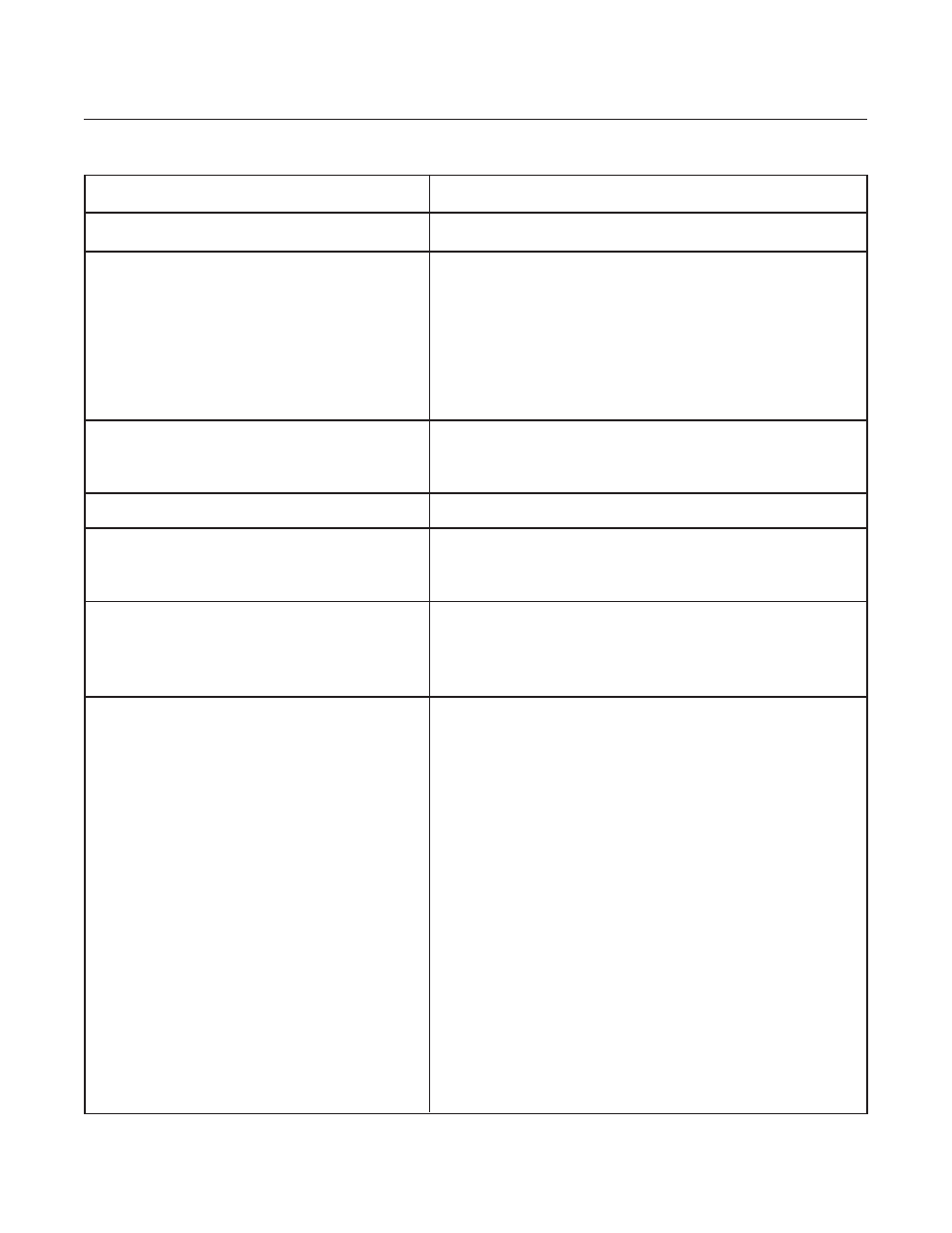

Section 4 Maintenance & Troubleshooting

Symptoms & Possible Causes

Corrective Action

5. No gas flow below some setpoint.

NOTE: When the setpoint is

decreased below this point, the

GF40/GF80/GF81

Series signal remains at

some value higher than the

setpoint.

Is the gas inlet/outlet differential

Verify that the pressure is correct for

pressure too high?

regulator to achieve proper pressure.

Is the GF40/GF80/GF81 Series leaking?

Check for contamination. Test the GF40/GF80/GF81 Series

for leak integrity. Replace the

GF40/GF80/GF81

Series

if leakage is detected.

6. Gas flow oscillates.

Is the

GF40/GF80/GF81

Series calibrated for the

Check the

GF40/GF80/GF81

Series side can label. Run

gas flowing?

a flow check to verify. If flow is incorrect,

replace the

GF40/GF80/GF81

Series.

Is there too much gas pressure

Verify that the pressure is correct for

across the

GF40/GF80/GF81

Series?

this gas and range. If required, adjust

regulator to achieve proper pressure

reading.

Are inlet and outlet pressures stable?

If outlet pressure is unstable, check for

(no oscillation or hunting) a faulty vacuum pump,

or hunting at a downstream valve.

Check inlet pressure on tool. A faulty

pressure regulator can make the

GF40/GF80/GF81

Series appear to oscillate.

Adjust inlet pressure up or down by 2

psig increments until hunting disappears.

Verify common gas pressure is

within range.

NOTE: Hunting or oscillation can be

contributed to multiple

GF40/GF80/GF81

Series sharing

a common gas manifold. Therefore,

inspect gas delivery sources to

the gas box (for example; two tools

sharing a common gas bottle and

calling for gas at the same time). Valve leak.

Unregulated gas pressure from Facilities.

Table 4-2 GF40/GF80/GF81 Series Troubleshooting Guide (Continued)