Brooks – Brooks Instrument GF81 User Manual

Page 43

4-5

Brooks

®

GF40/GF80/GF81 Devices

Installation and Operation Manual

X-TMF-GF40-GF80-Series-MFC-eng

Part Number: 541B161AAG

June, 2013

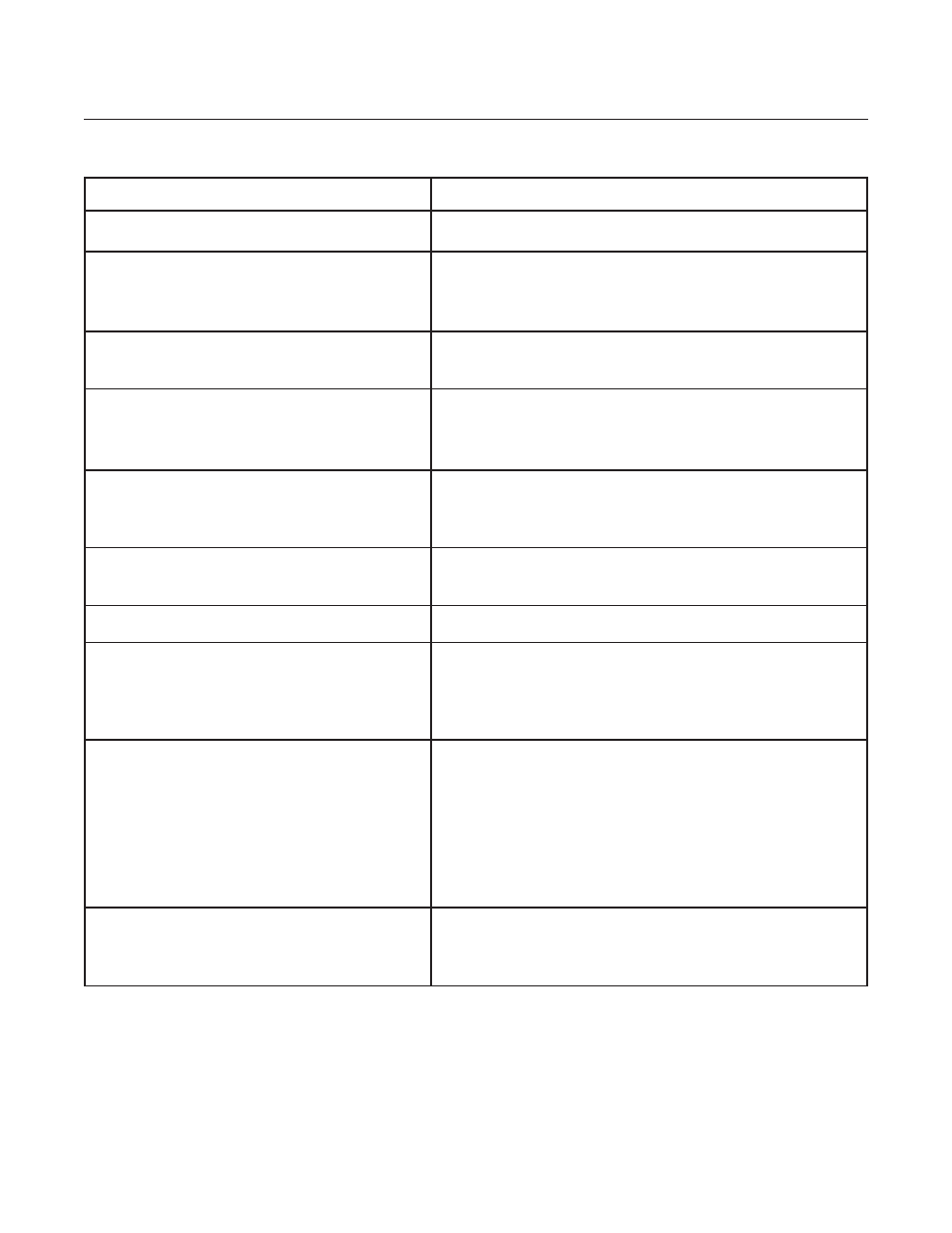

Section 4 Maintenance & Troubleshooting

Symptoms & Possible Causes

Corrective Action

2. Flow out of range (Continuted).

Is the device zero correct?

Zero the device according to zeroing

procedure in Section 2-16. Verify leak check rates

are OK.

3. No gas control; flow is at or

above maximum.

Is the gas pressure across the device

Verify that the pressure is correct for the gas and

too high?

range. If required, adjust inlet/outlet pressure to

achieve proper pressure reading.

Are system valves open, or is the

Use tool software to verify.

purge input activated?

Confirm that pin 12 is not connected to an active voltage

source.

Is the setpoint correct for the

Use tool software to verify.

required flow?

4. No gas flow above some setpoint.

NOTE: When the setpoint is

increased beyond this point,

the

GF40/GF80/GF81

Series signal remains at

some value lower than the set-point.

Is the gas inlet/outlet differential

Verify that the pressure is correct for

pressure sufficient?

the gas and range. If required, adjust

regulator to achieve proper pressure.

NOTE: If the pressure is too low,

the valve voltage to the

GF40/GF80/GF81

Series

will be at its maximum output. This condition

will cause internal GF valve heating and

inability to properly reach desired flow setpoints.

Is the

GF40/GF80/GF81

Series calibrated for the

Check

GF40/GF80/GF81

Series side label. Run a flow check

gas flow?

to verify. If flow is incorrect, replace the

GF40/GF80/GF81

Series with a unit that is calibrated properly.

Table 4-2 GF40/GF80/GF81 Series Troubleshooting Guide (Continued)