Climax BB3000 LINE BORING MACHINE User Manual

Bb3000 boring machine

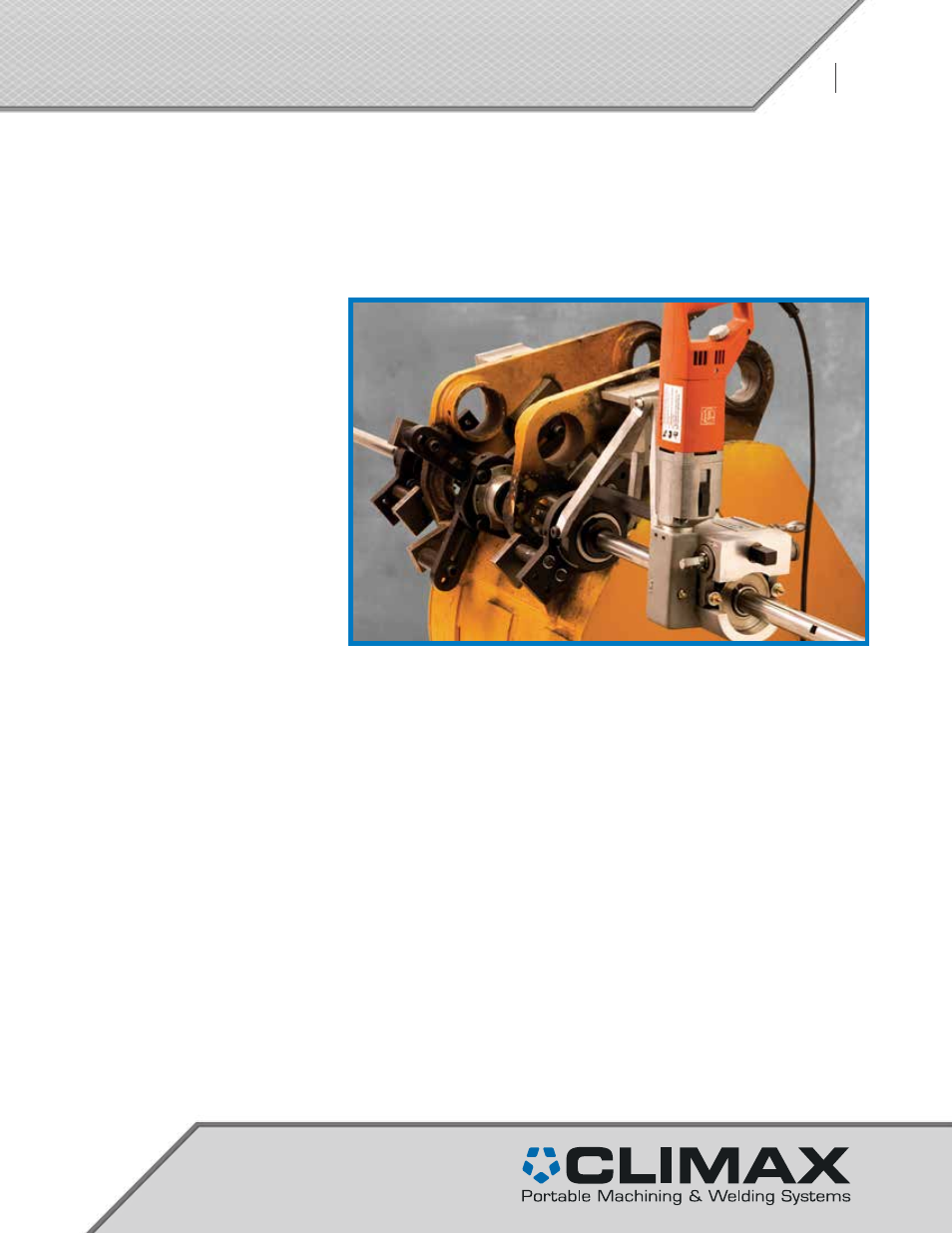

BB3000 Boring Machine

get buckets and loaders back to work

with effective on-site repairs.

If you have ever repaired worn hinge

points on loader arms or buckets, you

know how difficult it is to cut off the

worn area and try to weld on new

hinge points while keeping everything

lined up. A better way is to use the

Climax Model BB3000 Portable

Boring Machine. If the holes are not

badly damaged, you can simply weld

them up, attach the Climax Portable

Boring Machine, and re-bore them to

original dimensions. If the hinge

points are so damaged that the entire

area needs to be replaced, weld on

new sections with slightly undersized

holes, then quickly re-bore them to

original dimensions while keeping

everything in proper alignment.

Boring Capacity

• Bore from 1-½ - 5 inches (38.1 -

127.0 mm) in diameter, using the

bar and tool head.

• The 1-¼ inch (31.75 mm)

diameter bar is available in almost

any length in 1 foot (304.8 mm)

increments.

• Holes are positioned at 6 or 10

inch (152.4 or 254.0 mm) intervals

along the bar to hold 3/8 inch

square tool bits in the SAE inch

version, and 10 mm square tool

bits in the metric version.

• The clamp-on tool head covers

the 3-1/4 - 5 inch (76.2 - 127.0

mm) diameter range.

Powerful

• 1.0 Hp (0.74 kW), universal type

motor drives a 7.5:1 reduction

gear box; produces up to 90 ft-lbs

(122 N•m) of torque at the bar.

• Two-speed motor has bar speeds

ranging from 52 - 88, and 89 -

185 no load, freespeed rpm; 2 -

2.2 amps.

• Metal removal rate of up to 1

cubic inch/min (16.4 cm3/min) in

C1018 steel.

Compact Design

• The rotational drive extends only

19 inches (482.6 mm) out from

the mounting bracket and 14

inches (355.6 mm) from the bar to

the top of the motor. The

rotational drive can be mounted

with the motor in any position

around the bar if

clearance is a problem.

• Rotational drive with feed rack

and anti-torque scissors weighs

only 35 lbs. (15.9 kg).

Automatic Power Feed

• Infinitely variable, reversible

power feed has a 10 inch (254.0

mm) stroke. An automatic feed

stop mechanism disengages the

feed at the end of the 10 inch

stroke.

• Feed rate is from 0 - 0.018 inches

(0 - 0.46 mm) per revolution.

2013

BB3

1