Intrinsically safe module wiring – Franklin Fueling Systems TS 550 evo Fuel Management System Installation User Manual

Page 19

19

Intrinsically Safe Module Wiring

Always lock out and tag electrical circuit

breakers while installing or servicing this

equipment and any related equipment. A

potentially lethal electrical shock hazard

and the possibility of an explosion or fire

from a spark can result if the electrical

circuit breakers are accidentally turned on

during installation or servicing.

Important: Intrinsically safe wiring cannot be run in

the same conduit as non-intrinsically safe

wiring. Conduit knockouts for IS and non-

IS module wiring are clearly identified in

Figure 6 on page 10 for your reference.

IS modules can be identified by their blue

faceplates and should always be installed to

the right of the moveable isolation barrier.

If local codes do not require the use of

conduit, cable glands must be used at all

enclosure knock-outs.

Gaps larger than 0.06 inch (1.5 mm) will

violate safety approvals. Be certain to

provide adequate IS and non-IS wire

separation.

Franklin Fueling Systems recommends that each run of IS

wiring not exceed 1500 feet (450 m) using any 2-conductor

shielded cable or the cables/wires recommended in the

Standard Installation Materials chapter. If you are not using

the recommended cables/wires as set out in the Standard

Installation Materials chapter or need to run wiring beyond

1500 feet (450 m), then please contact Technical Support.

The IS modules in the TS-550 evo console were certified as

associated apparatuses using the “Entity Concept.” Under

this concept, the IS apparatus (field device) has assigned

parameters which, when properly matched to those of an

associated apparatus, will constitute an intrinsically safe

system. If there are none available however, values of 60

pF / foot (200 pF / m) for capacitance per wire pair and 0.2

uH / foot (0.7 uH / m) for inductance may be used. Refer to

the associated apparatus’s control drawing for acceptable

cable run length calculations.

The 3WSNS has also been evaluated using the “System

Concept” for the specific sensors indicated on page 21.

When these sensors are used, cable must be limited to

1500 feet.

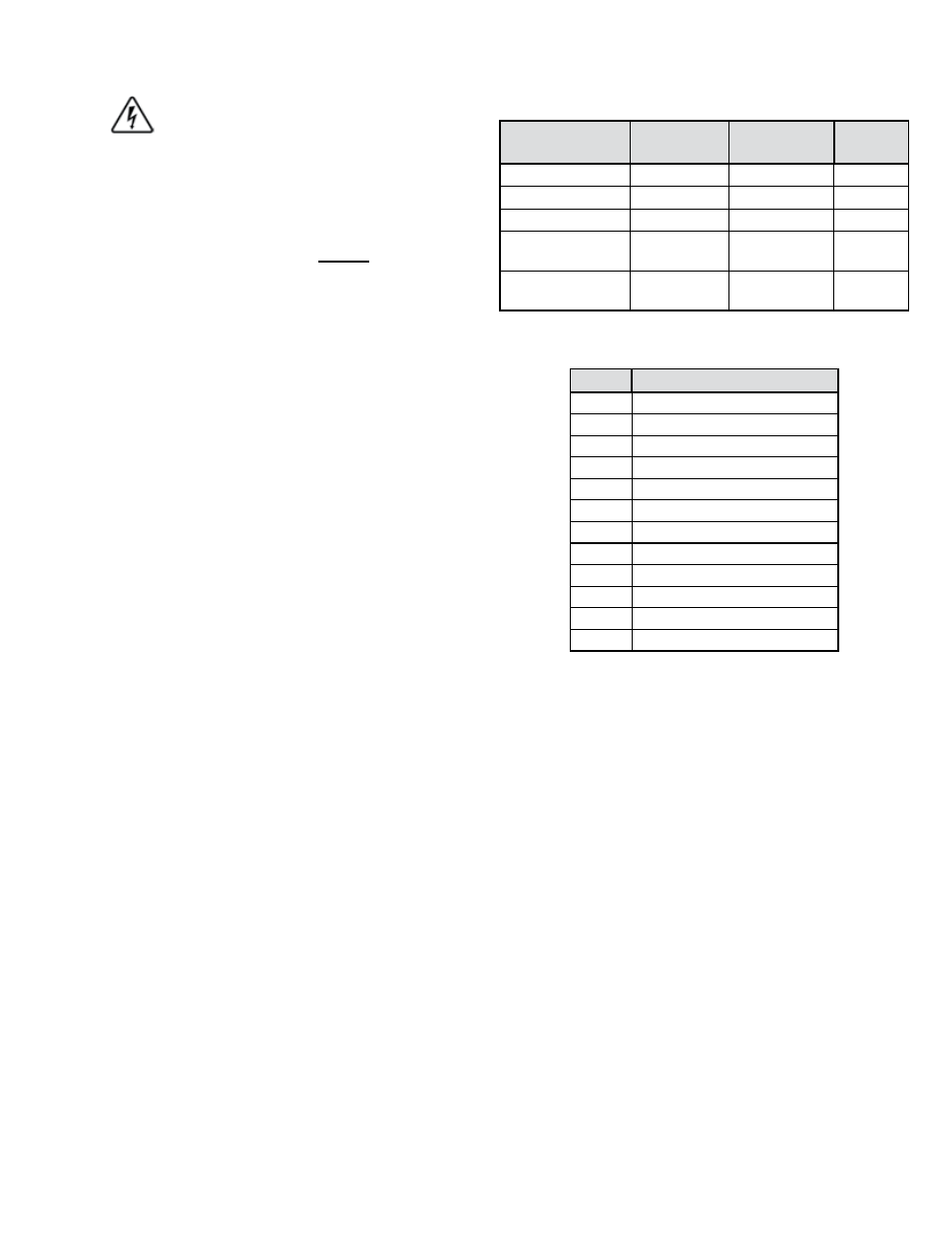

Associated apparatus parameter types and how they can be

compared to IS apparatus parameter values are shown in

the table below.

Parameter

Associated

Apparatus

Comparison

IS

Device

Maximum Voltage

Uo

<

Ui

Maximum Current

Io

<

li

Maximum Power

Po

<

Pi

Total unprotected

capacitance

Co

>

Ci + Cc

Total unprotected

inductance

Lo

>

Li + Lc

Standard Terms

Term Definition

Uo

Maximum Output Voltage

Ui

Maximum Input Voltage

Io

Maximum Output Current

Ii

Maximum Input Current

Po

Maximum Output Power

Pi

Maximum Input Power

Co

Maximum External Capacitance

Ci

Maximum Internal Capacitance

Cc

Cable Capacitance

Lo

Maximum External Inductance

Li

Maximum Internal Inductance

Lc

Cable Inductance

Danger