N-x144_iom_21 – Cla-Val X144 Technical Manual User Manual

Page 21

SECTION 4: Maintenance and Repair

4.1 – Routine Maintenance

CAUTION:

Always disconnect the power supply, isolate and depressurize the system before performing any

maintenance or repair. Failure to so may result in injury to personnel or damage to equipment.

The X144 e-FlowMeter does not have any moving mechanical parts and so is not affected by fatigue wear

from mechanical stress. The system should be inspected routinely for leaks. An inspection should consist of

the actions in steps 1-2 procedure outlined in section 3.1. It is recommended the equipment be turned off during

inspection.

4.2 – Cleaning debris from measurement cylinder

If the readings from the X144 e-FlowMeter begin to act in an unreliable manner, then

the measurement cylinder should be inspected and cleaned out to ensure proper operation.

Required Tools:

• Insertion tool

• Adjustable wrench

• Small pick or small screw driver for clearing the debris

• Tweezers or small needle-nosed pliers

Procedure

1) Close the shut-off valves to stop the flow of water.

2) Disconnect all wiring.

3) Go through the removal steps (section 3.2) to remove the X144

e-FlowMeter from the Control Valve,using the provided Insertion

Tool

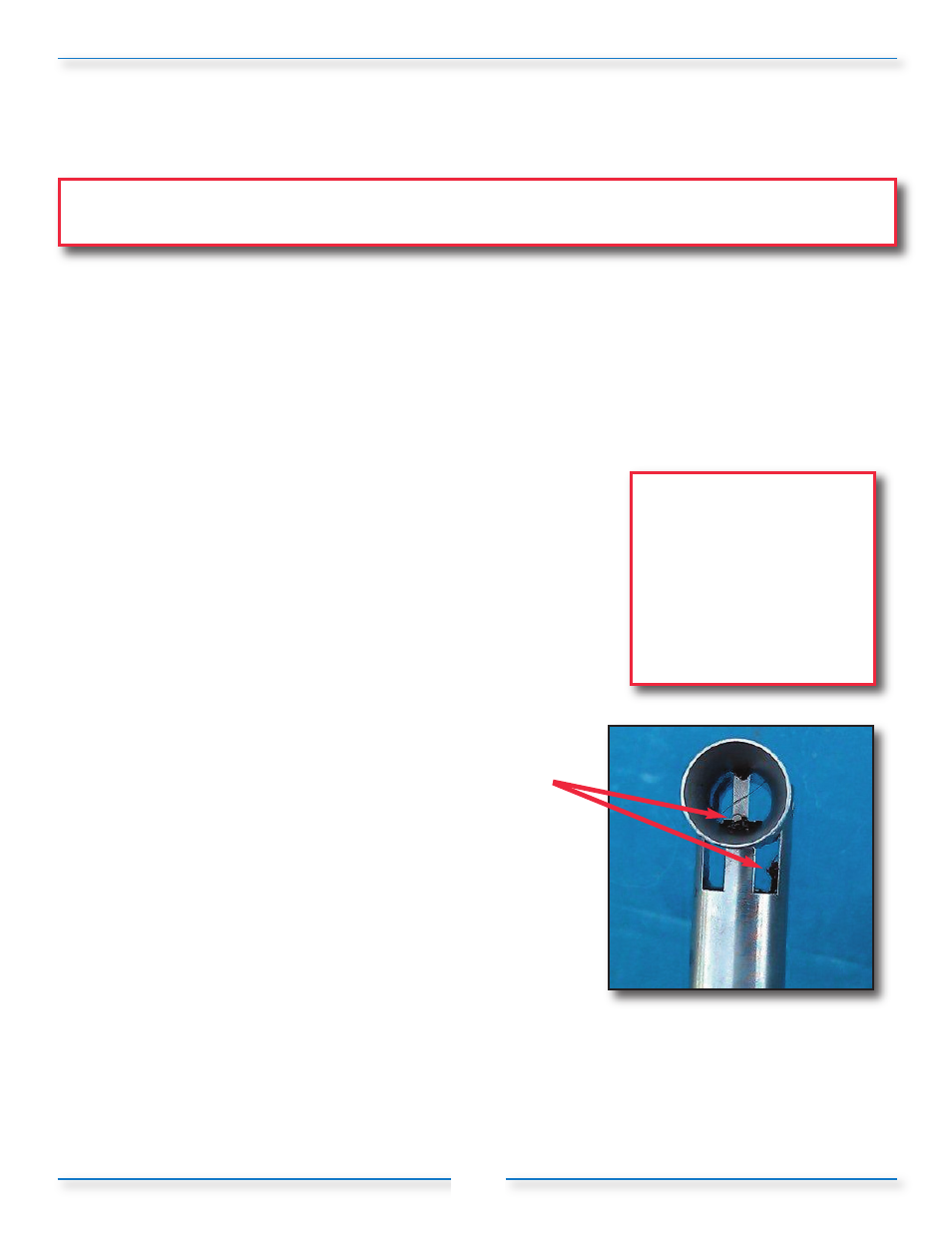

4) With the sensor still removed from the threaded insert, inspect

measurement cylinder; looking specifically for debris caught on

the bluff body, as shown in Figure 4-1.

5) Use pick or small screw driver and tweezers to remove all of

the debris from the measurement cylinder, bluff body and

anywhere else that it has accumulated.

6) Reinstall X144 according to the installation steps in section 2;

verify operation per operation instructions in section 3.

4.3 – Dealing with Sensor Tip Damage

1) If the Sensor Tip is bent, broken or damaged in the course of

handling or installation, the X144 e-FlowMeter will not function

properly. The sensor should be straight with respect to the

sleeve. Since it is designed to sense micro-motion, if the sensor

is forced to enough to detect the movement with the naked eye, it

may have been damaged. In that case, contact Cla-Val

Customer Service.

18

Figure 4-1

CAUTION 1:

Failure to use

the provided Insertion Tool

WILL

result in damage to

the e-FlowMeter

CAUTION 2:

To avoid

injury, isolate the valve and

bleed pressure prior to

removing the e-FlowMeter