Cla-Val 501A Series User Manual

Series 501a, Wafer swing check valve, Specifications

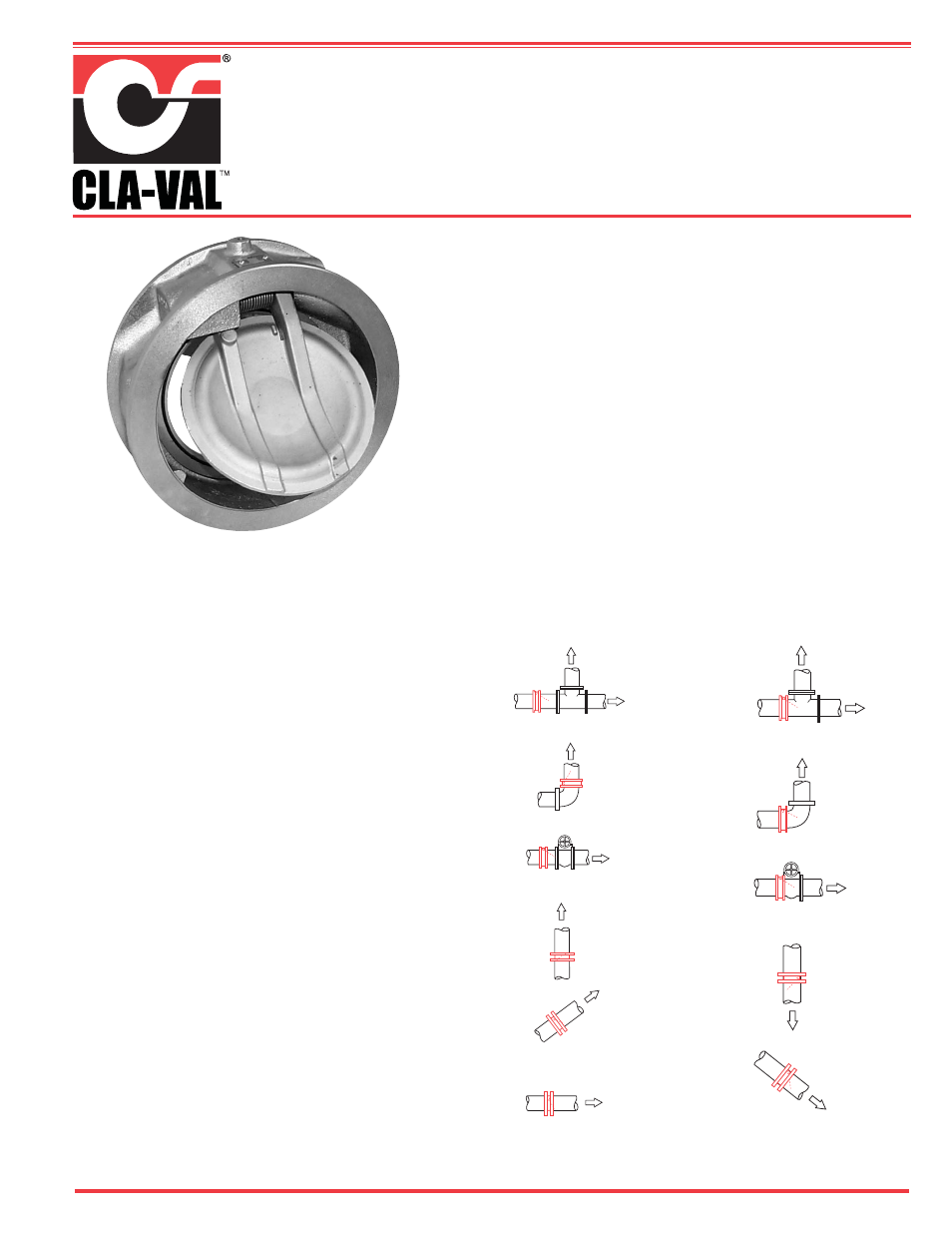

Wafer Swing Check Valve

Recommendations for Installation Position

1. Install the valve in horizontal or upward flow for proper valve closure.

Caution: Do not use with reciprocating compressors, or in other pulsating services.

SPECIFICATIONS

The wafer swing check valve shall have torsional a

spring-assisted fast closure to minimize possibility of

water hammer. The valve shall be constructed of

either cast iron or steel body.

The body shall have a machined dovetail groove to

retain a field replaceable Nitrile (Buna-N

®

) Seal that

provides water-tite shut-off at low/high pressure

The valve disc/arm assembly shall be one piece

design utilizing an integral disc arm for connection to

the shalt for positive shut-off and no disc flutter.

For corrosion resistance the valve shall be

Electroless Nickel Plated

Valve Body:

2" -12" Cast Iron ASTM A48

Electroless-Nickel Plated

14" - 30" Carbon Steel ASTM A216 WCB

Electroless-Nickel Plated

Valve Trim:

2" - 12" 316 Stainless Steel ASTM A23,

14" - 30" Carbon Steel ASTM A216 WCB

Electroless-Nickel Plated

Seat O-ring: Nitrile, Other Seat Materials Available

All materials conform to ASTM specifications, The valve

shall be a Cla-Val Series 501A Wafer Swing Check Valve,

Newport Beach, CA 92659-0325

Series 501A

•

Low Head Loss

•

Watertight Nitrile Seat

•

Spring Assisted, Fast Closure

•

Extremely Light Weight

DESCRIPTION

Cla-Val Series 501A Wafer Swing Check Valve has a quick,

spring-assisted closure that minimizes the possibility of

water hammer. The swing check design offers low head loss

and a full-flow passageway making it ideal for water or waste-

water applications. The short lay length of the valve allows

for a space-saving design. It is available in sizes 2” to 30”,

with either a 125 lb. or 150 lb. pressure class rating.

Available in a variety of materials, including all 316 stain-

less steel, the Cla-Val Wafer Swing Check Valve uses a

standard soft seat to ensure a drip-tight seal. For ease of

installation, valves 6” and larger are supplied with a tapped

hole to mount an eye bolt for lifting. All materials conform

to ASTM specifications, ensuring performance reliability.

NORMAL FLOW

NORMAL FLOW

NORMAL FLOW

Note Hinge

Position

NORMAL FLOW

Note Hinge

Position

NORMAL FLOW

NORMAL FLOW

NORMAL FLOW

NORMAL

FLOW

Note Hinge

Position

Typical Applications with

Correct Valve Location

Avoid These Applications

with Incorrect Valve

Location

Standard Style

2”-12”

Note: Allow minimum

(2) pipe diameters

clearance downstream

of check valve with

disc open to promote

smooth flow