Cla-Val 583 User Manual

Tite seal” foot valves, Cla-val, Series installation / operation / maintenance

CLA-VAL

Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325

• Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: [email protected] • Website cla-val.com

©

SERIES

INSTALLATION / OPERATION / MAINTENANCE

N-583

“Tite Seal” Foot Valves

583

INTRODUCTION

The Cla-Val Series 583 Foot Valves are designed to give years of

trouble-free operation. “Tite Seal” Foot Valves are resilient seated for

handling water and other fluids. The size and non shock cold working

pressure (CWP), and Model No. are stamped on the nameplate. The

valve is intended for installation on the inlet suction of the centrifugal

pump.

Note: The valve is not intended as a block valve for line testing

above the valve rating.

RECEIVING AND STORAGE:

Upon receipt inspect for damage in shipment. Unload valves

carefully without dropping. Do not use slings or chains around valves

spokes or screen assembly for lifting.

Keep valves crated until installed to prevent weather related damage.

For storage greater than six months, store indoors.

OPERATION:

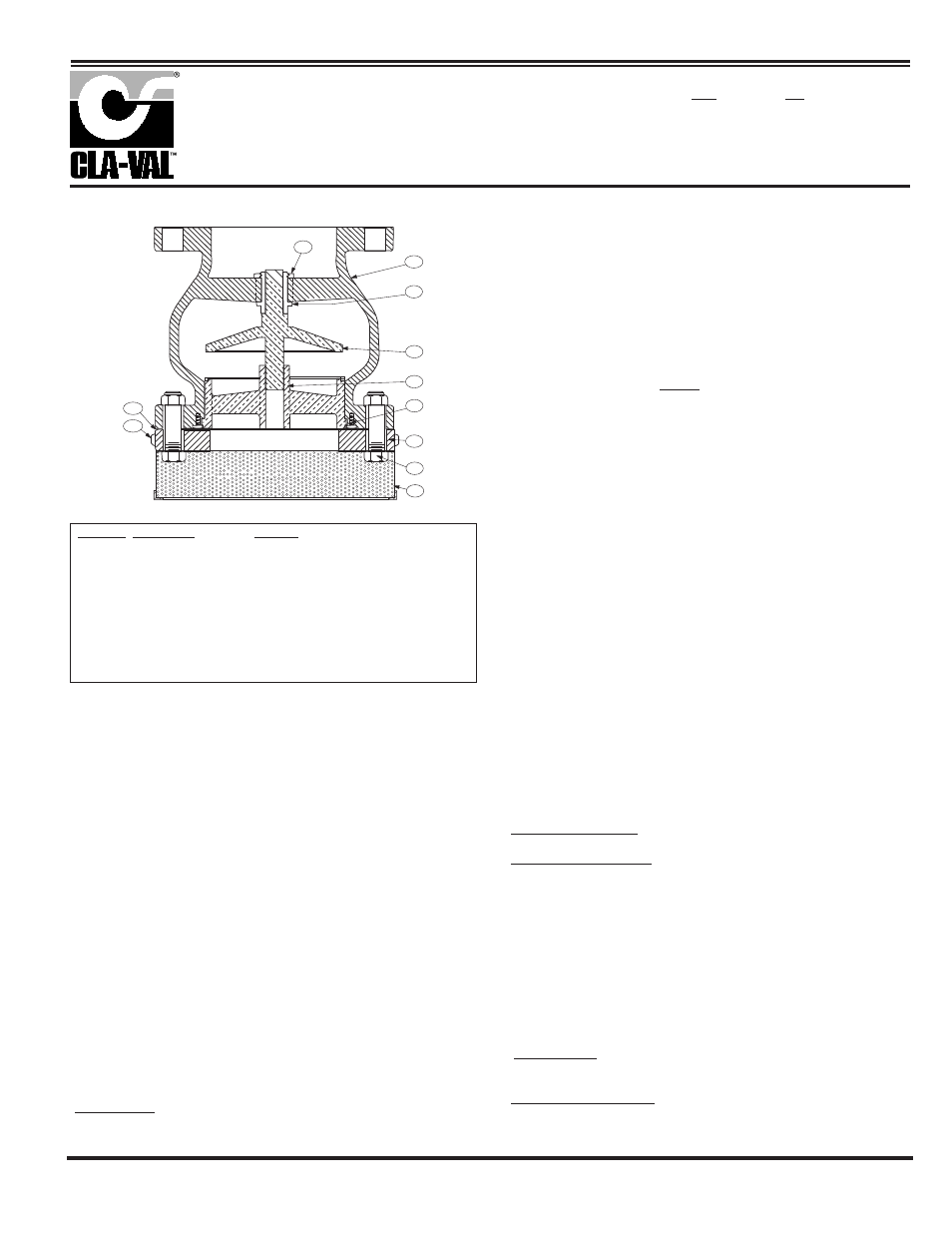

See (Fig. 1) Valve consists of a body, a plug and a seat with resilient

seal. The valves are designed to maintain prime (flooded suction)

when installed on inlet of the suction piping. The “Tite Seal” provides

water tight shutoff and the strainer prevents debris entering the valve

and piping system.

The seat with seal are rigidly connected to the inlet of the Foot Valve.

As flow enters the valve, thru the inlet the plug is lifted into open

position. Upon pump shut down, the return flow instantly closes the

plug against the seat to maintain the pump prime.

CONSTRUCTION:

The Series 583 “Tite Seal” Foot Valve is constructed of cast iron body

with bronze or stainless steel trim.

See details of materials and construction illustrated in figure 1 The

body (1) comes with flanged outlet for bolting to the suction piping.

The body is fitted with a bronze seat (2). The plug (3) is guided by a

bronze bushing (7) locked in the body. “Tite Seal” closure is made

when the resilient seal is compressed by the closed plug. A stainless

steel strainer assembly (12) prevents debris from entering the valve.

5

1

4

3

2

8

9

10

7

6

6

OUTLET

Item No.

1

2

3

4

5

6

7

8

9

10

Description

Body

Seat W/ Buna-N

®

Plug

Bushing

Retainer

Gasket

Screen Retainer*

Ring Plate

Bolt Assembly

Screen

Material

Cast Iron ASTM A126, Class B

Bronze ASTM B584, Alloy C83600

Bronze ASTM B584, Alloy C83600

Bronze ASTM B16, Alloy C83600

Brass

Compressed Non-Asbestos Fiber

Stainless Steel T304, ASTM F879

Carbon Steel ASTM A36

Alloy Steel SAE, Grade 2

Stainless Steel T304, ASTM A240

INSTALLATION RECOMMENDATIONS:

Install with arrow flow direction vertical flow up and with the Foot

Valve Strainer in the wet well or water source. The strainer bottom

should be minimum (1) size diameter from the bottom of the wet

well floor.

FLANGED END: The valve should be mated to ANSI Class 125#

flat-faced flange using a resilient ring gasket. The bolts should be

ASTM A307 Grade B or SAE grade 2 Carbon Steel. Lower Foot

Valve into wet well using slings or chains around the valve body.

Lubricate the flange bolts before tightening around the flange.

Lightly tighten bolts until gaps are eliminated.

Torque the bolts in graduated steps using the cross-over tightening

method. If leakage occurs, allow gasket to absorb fluid and check

torque and leakage after 24 hours. Do not exceed bolt rating or

crush gasket more than 50% of its thickness.

MAINTENANCE:

The Series Foot Valve requires no lubrication or maintenance. If

flow stops or pump cavitation develops It may be necessary to

clean debris from Foot Valve inlet by backflushing the valve or

physically cleaning the outside surfaces of the strainer.

WARNING:

Strainer flange must not be removed with water pres-

sure in the Foot Valve or the seat may come loose causing damage

or injury.

TROUBLESHOOTING:

Possible problems and solutions follow to assist troubleshooting

the Foot Valve.

• Leakage at Flanges: Tighten flange bolts, replace gasket.

• Valve leaks when shut: Flush debris from seat by cycling pump. If

leakage continues check the following items and make the

corrections.

1. Verify there is no damage to the rubber seal. Replace if worn

or damaged.

2. Check the metal seat in the body is clean and free of scale

and scratches.

3. Verify that the working pressure does not exceed cold working

pressure (CWP) shown on the foot valve nameplate.

4. Drain wet well with pressure on valve and check strainer

flange seal. Retighten strainer flange bolts or replace gasket.

• Valve Slams: If adjustable pump, add time to the shut down

sequence. Check for trapped air in the pump header, Check inte-

rior of valve bushing for deposits or debris.

• Noisy Pump Operation: Flow noise is normal but loud flow noise

similar to hammering may be due to cavitation. Check for debris on

outside surfaces of the strainer or floor wetwell.

*Recommended Spare Parts