Xylem OxiTopIS OC100 User Manual

Page 91

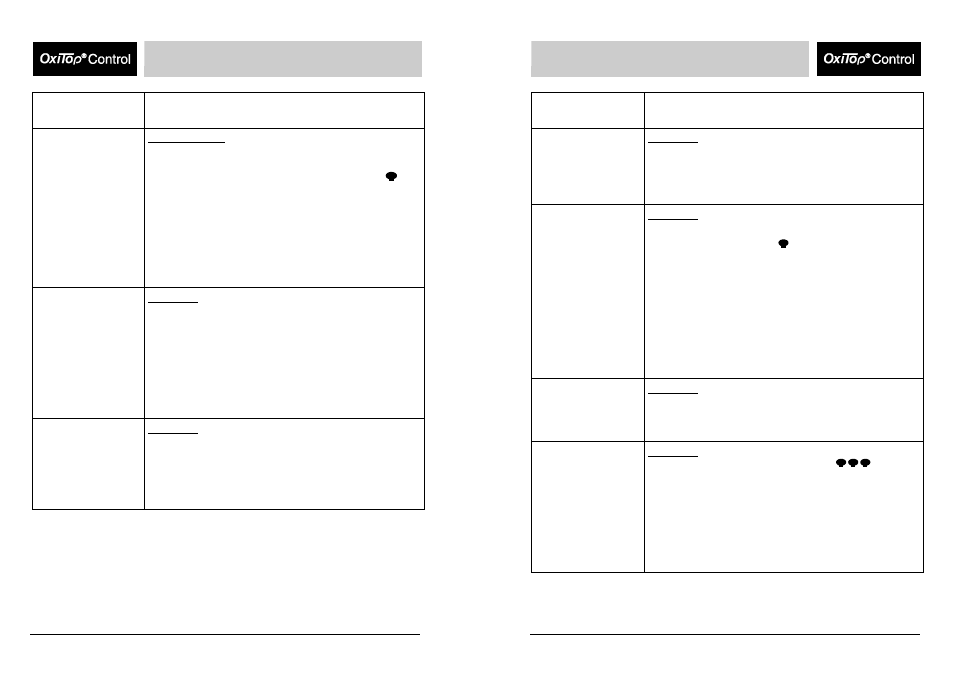

What to do if...?

What to do if...?

90

BA31114e5 07/2006

BA31114e5 07/2006

91

Requirements /

Problems

Procedure / Problem solutions

Measuring head

unintentionally started

for measurement

Measuring head

started with incorrect

settings

Measuring head is

required for another

sample

Problem solution

The measuring head can be released again through the

command Reset/release:

Chapter “GLP/Tools

-

Maintenance - Reset/release

“

.

The controller guides you further through the operation.

If only one measuring head is stored under the

corresponding sample number (in the routine BOD

operating mode, this is always the case), the controller

automatically erases the sample in the sample

management.

Search for the

defective measuring

head

Procedure:

• Perform a measuring head reaction test (see above).

A measuring head that repetitively shows no reaction to

the test is defective.

• If the defective measuring head cannot be established

in this way, perform the measuring head check (see

“Single check”). In doing this, each individual measuring

head must be checked until the defective measuring

head has been found.

A measuring head is

missing or is defective.

Requirement:

To determine the

corresponding sample

Procedure:

Call up the function “Call up data” from the sample

management for each individual unfinished sample. The

corresponding sample can be determined by this.

For subsequent error handling, see the chapter “Sample

management - Call up data”.

Requirements /

Problems

Procedure / Problem solutions

The precision and

sealing of the system

sample bottles plus

measuring head

should be checked

Procedure:

See the chapter “GLP/Tools

-

Check - Cal test “

Measuring head check

(single check)

(To which running

sample does the

selected measuring

head belong?)

Procedure:

Single check method:

menu “GLP/Tools

-

Check -

info”

• The controller guides you further through the operation.

• All single information on the state of the measuring

heads is listed, i.e. the measuring head responds.

• The check can be undertaken at any time without

affecting the measurement that is running.

• If no reaction at all can be determined, the batteries

should be changed and the measuring head check

repeated.

• The measuring precision cannot be checked with this!

The measuring

precision of the

measuring head

should be checked.

Procedure:

Pneumatic test (PT) of the measuring head:

see the chapter “GLP/Tools

-

Check - Pneumatic test”

Perform measuring

head reaction test

Procedure:

• Menu “GLP/Tools

-

Check - Show all

”

:

• All optically attainable measuring heads must flash for

approx. 5 seconds independent of their status.

• The check can be undertaken at any time without

affecting the measurement that is running.

• This test only checks the reaction to commands.

• If no measuring head reacts, the controller should be

checked.