Advanced instruments inc, Sampling – Analytical Industries GPR-1600 Series Trace PPB Oxygen Analyzer User Manual

Page 45

Advanced Instruments Inc.

45

Sampling

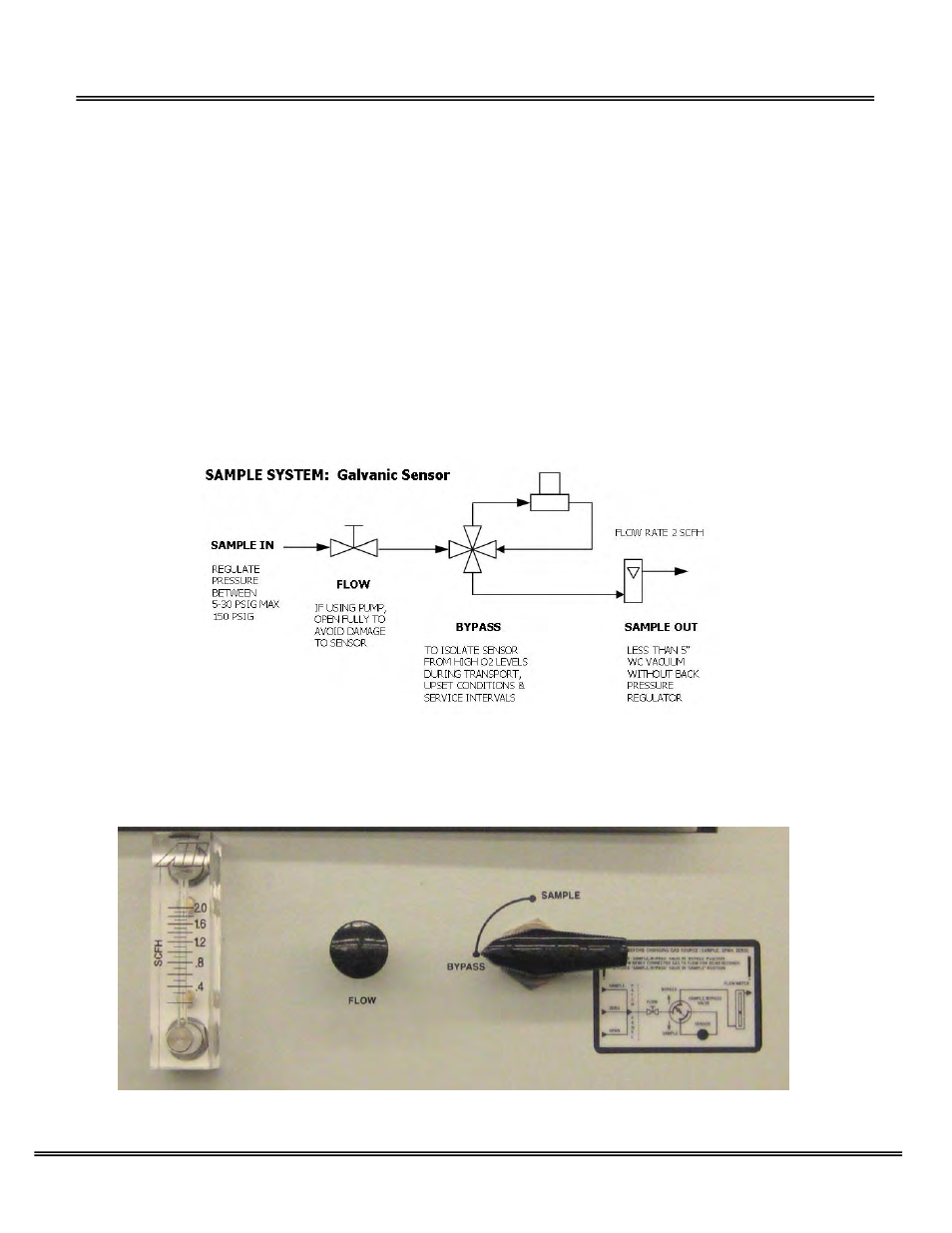

Process ppm oxygen analyzers require positive pressure to flow the sample gas by the sensor to measure the oxygen

concentration in a sample gas. See Pressure & Flow under Installation in section 3 Safety Guidelines. To assure optimal

performance: connect gas lines with metal tubing, quality compression type fittings to minimize leaks, follow pressure and flow

recommendations and avoid exposing the sensor to air and high oxygen concentrations for prolonged periods of time (this does

not include the 5 minutes it should take to air calibrate the analyzer once a week).

The sample must be properly presented to the sensor to ensure an accurate measurement. In standard form the GPR-1600 is

designed with a sample system that complements the performance capabilities of the advanced oxygen sensor and enables the

user to isolate the sensor from exposure to high oxygen concentration which results is a substantial increase is user

productivity.

For ppb and ppm trace oxygen measurements, the sensor is exposed to sample gas that must flow or be drawn through the

analyzer’s internal sample system. This unique sample system, when operated accordingly to the instructions in this Owner’s

Manual, can significantly increase user productivity by minimizing the sensor’s exposure to ambient air or high oxygen

concentrations which contribute to the significant amount of downtime associated with competitive analyzers.

The advantages of the bypass sample system include:

¾ Supplying the analyzer with the sensor it was qualified with.

¾ Isolating the sensor during transport, calibration and maintenance intervals when changing gas line connections.

¾ Isolating the sensor from exposure to high oxygen levels during upset conditions which extend sensor life.

¾ Purging the air (or high oxygen levels above 1,000 ppm) trapped in the gas lines following a process upset.