Advanced instruments inc, Installing the oxygen sensor – Analytical Industries GPR-1600 Series Trace PPB Oxygen Analyzer User Manual

Page 21

Advanced Instruments Inc.

21

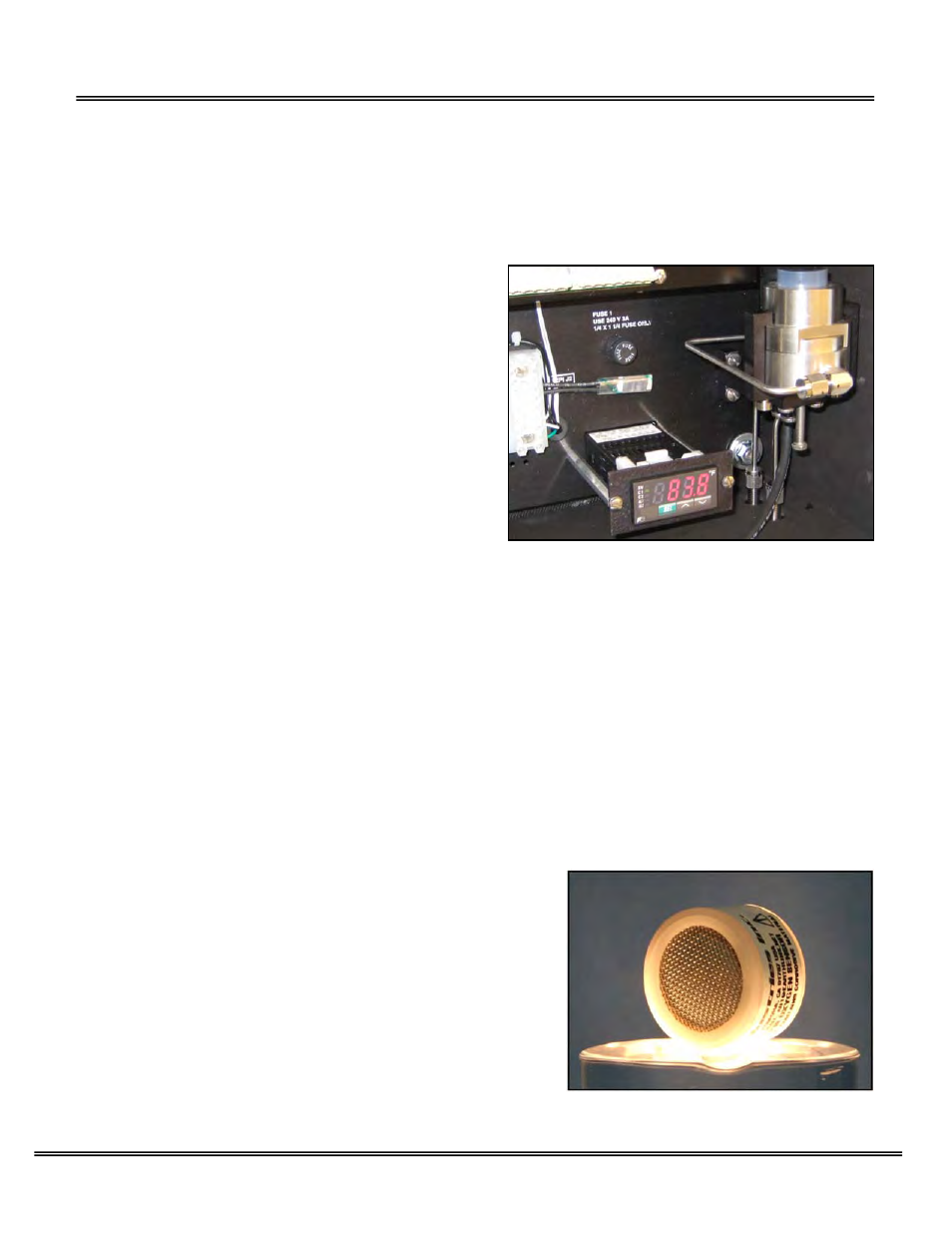

Temperature Controlled Heater System with Runaway Protection Circuit

The standard GPR-1600 Series analyzer is not equipped with the heater system. However, in anticipation of very low ppm (high

ppb) oxygen analysis, the user may elect to add the heater system. If the analyzer is equipped with an optional temperature

controlled heater system, open the front door of the analyzer to access it. This unit is a PID controller which operates between

0-99

°F. The controller is programmed to maintain the temperature at 85°F.

Caution: Do not change this setting. A higher temperature

setting may drastically reduce sensor life and possibly cause

damage to the electronic circuitry of both the controller and the

analyzer.

Warning:

Keep the front door securely fastened and closed when

the temperature controller is ON.

When power is applied to the temperature controller, the controller

tunes itself to eliminate and/or minimize the over/under shoot of

temperature from the set point. It is recommended that at initial

start-up, when replacing the oxygen sensor or when trouble

shooting, turn off the power to the heater or set the temperature

set point at 60

°F (to turn the heater off) to prevent overheating

the analyzer. When operating the analyzer under normal

conditions, set the temperature controller at 85⁰F.

Changing the display value from

°F to °C:

1. Push the UP ARROW and ENTER buttons down for 5 seconds to access the SECURE MENU

2. Press INDEX to advance to the F-C MENU

3. Select

°C or °F by pressing the UP ARROW key

4. Press the ENTER key when F-C starts flashing on the display

5. Press INDEX to exit the SECURE MENU

Heater Runaway Protection

Part of the optional temperature controlled heater system is a heater runaway protection circuit that protects the electronics in

the event the temperature controller should fail and thereby allowing the heater to runaway damaging the components inside

the analyzer.

The runaway protection is provided by a J2 type device positioned between the temperature controller and the heater. This

device cuts-off power to the heater if the temperature inside the analyzer exceeds 70

°C. Should the J2 device cut power to the

heater, correct the problem and reset the runaway protector device by exposing it to 0

°C for a few minutes (a refrigerator

freezer will do).

Installing the Oxygen Sensor

The analyzer is equipped with an internal oxygen sensor that has been

tested and calibrated by the manufacturer prior to shipment and is fully

operational from the shipping containers. The sensor has been installed at

the factory , however, it may be necessary to install the sensor in the field.

Caution: Review procedure before proceeding, mainly 2 and 9.

Caution: DO NOT open the oxygen sensor. The sensor contains a corrosive

liquid electrolyte that could be harmful if touched or ingested, refer to the

Material Safety Data Sheet contained in the Owner’s Manual appendix.

Avoid contact with any liquid or crystal type powder in or around the sensor

or sensor housing, as either could be a form of electrolyte. Leaking sensors

should be disposed of in manner similar to that of a common battery in

accordance with local regulations.

Procedure: