Advanced instruments inc, Accuracy overview – Analytical Industries GPR-1600 Series Trace PPB Oxygen Analyzer User Manual

Page 13

Advanced Instruments Inc.

13

Accuracy Overview

Single Point Calibration: As previously described

the galvanic oxygen sensor generates an electrical

current proportional to the oxygen concentration in

the sample gas. In the absence of oxygen the sensor

exhibits an absolute zero, e.g. the sensor does not

generate a current output in the absence of oxygen.

Given these linearity and absolute zero properties,

single point calibration is possible.

Pressure: Because sensors are sensitive to the

partial pressure of oxygen in the sample gas their

output is a function of the number of molecules of

oxygen 'per unit volume'. Readouts in percent are

permissible only when the total pressure of the

sample gas being analyzed remains constant. The

pressure of the sample gas and that of the calibration

gas(es) must be the same (reality < 1-2 psi).

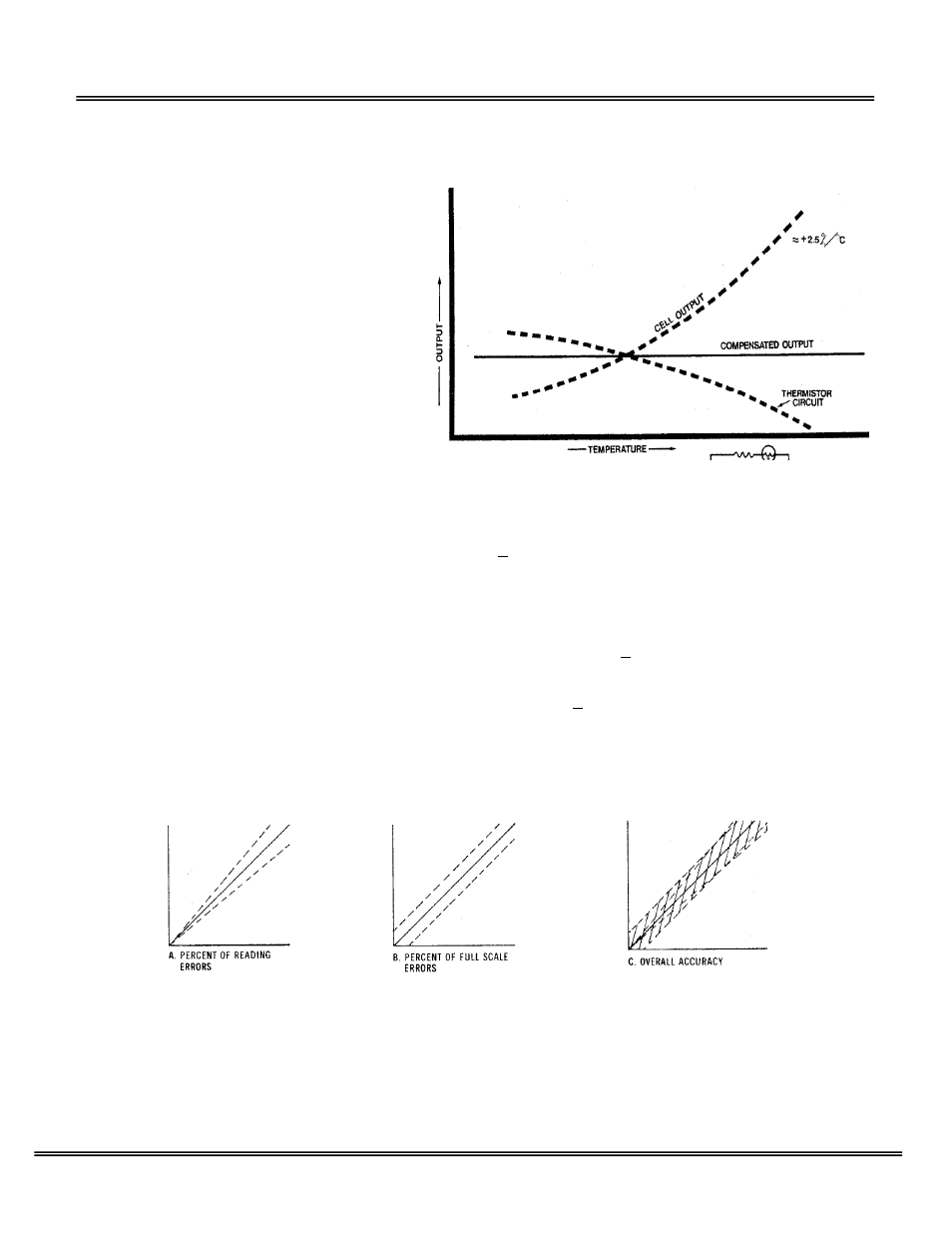

Temperature: The rate oxygen molecules diffuse into the sensor is controlled by a Teflon membrane otherwise known as an

'oxygen diffusion limiting barrier' and all diffusion processes are temperature sensitive, the fact the sensor's electrical output

will vary with temperature is normal. This variation is relatively constant 2.5% per ºC. A temperature compensation circuit

employing a thermistor offsets this effect with an accuracy of +5% or better and generates an output function that is

independent of temperature. There is no error if the calibration and sampling are performed at the same temperature or if the

measurement is made immediately after calibration. Lastly, small temperature variations of 10-15º produce < 1% error.

Accuracy:

In light of the above parameters, the overall accuracy of an analyzer is affected by two types of errors:

1) those producing 'percent of reading errors', illustrated by Graph A below, such as +5% temperature compensation

circuit,

tolerances of range resistors and the 'play' in the potentiometer used to make span adjustments and

2) those producing 'percent of full scale errors', illustrated by Graph B, such as +1-2% linearity errors in readout devices, which

are really minimal due to today's technology and the fact that other errors are 'spanned out' during calibration.

Graph C illustrates these 'worse case' specifications that are typically used to develop an analyzer's overall accuracy statement

of < 1% of full scale at constant temperature or < 5% over the operating temperature range. QC testing is typically < 0.5%

prior to shipment.

Example 1: As illustrated by Graph A any error, play in the multi-turn span pot or the temperature compensation circuit,

during a span adjustment at 20.9% (air) of full scale range would be multiplied by a factor of 4.78 (100/20.9) if used for

measurements of 95-100% oxygen concentrations. Conversely, an error during a span adjustment at 100% of full scale range is

reduced proportionately for measurements of lower oxygen concentrations.

Refer to the Calibration section for additional details.