Advanced instruments inc – Analytical Industries GPR-1600 Series Trace PPB Oxygen Analyzer User Manual

Page 44

Advanced Instruments Inc.

44

CALIBRATION

COMPLETE

Following a successful calibration, the system returns to the “Sample” mode and it will be necessary to reconnect the sample

gas line as follows:

Span Gas Calibration:

Assure there are no restrictions in vent line.

Regulate the pressure between 5-30 psig and set the flow rate to 2 SCFH for Fuel Cell sensors.

If the analyzer is equipped with a SAMPLE/BYPASS valve, place it in the BYPASS position.

Disconnect the span gas line and install the sample gas line.

Keep the SAMPLE/BYPASS valve in the BYPASS position.

Allow the sample gas to flow for 1-2 minutes to purge the gas lines inside the analyzer.

Place the SAMPLE/BYPASS valve in the SAMPLE position.

If the analyzer is not equipped with a SAMPLE/BYPASS valve:

Allow the sample gas to flow for 1-2 minutes to purge the air trapped in the sample gas lines.

Disconnect the span gas line and install the purged sample gas line.

Air Calibration:

The sample gas should still be flowing, if necessary open the FLOW valve.

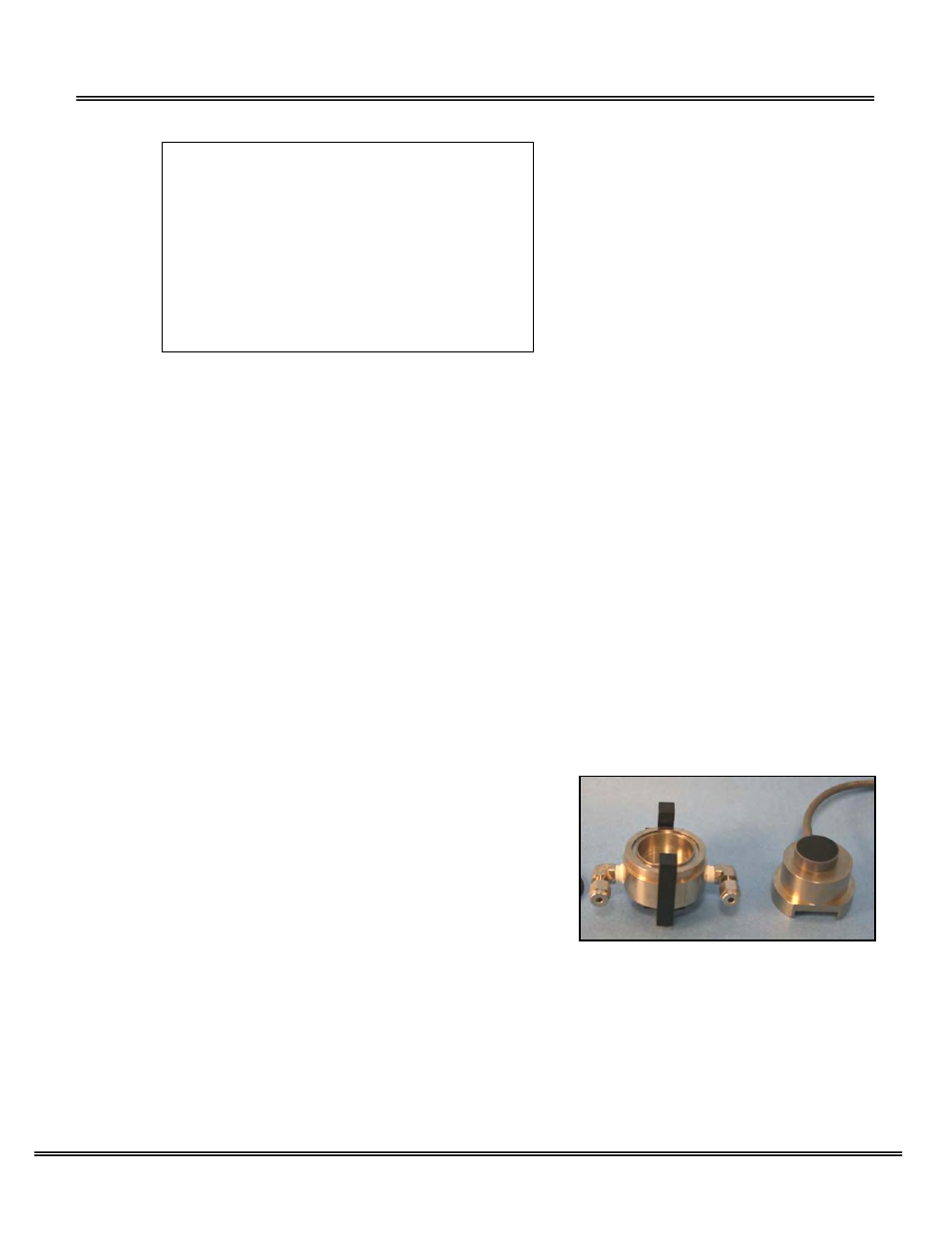

Reassemble the sensor housing.

Place the sensor face down in the bottom section of the sensor housing.

Ensure the o-ring is in place.

Install the upper section by gently pushing it

straight down.

Ensure the PCB contacts the two gold pins.

Rotate the upper section of the sensor housing

90º to engage the clamp.

Using the 5/16 wrench supplied tighten the clamp

bolt located in the center of the bracket attached

to bottom section with the elbow fittings to

secure the sensor housing.

Close the front door of the analyzer.