Installation, 1. equipment installation, 2. general – GE Industrial Solutions ASTAT-IBP Plus User Manual

Page 24

Catalog Numbers

Wire Range

Torque, in-lb

CI2K, QI2L, QI2Y, QI2M, QI2Z, QI2N

#14-#2 AWG

125

QI2P, QI2Q

#6 AWG-350 kcmil

275

QI2R, QI2S

#2 AWG-2x250 kcmil (or 1x600 kcmil)

550

5-1. Equipment installation

CAUTION! DISCONNECT POWER BEFORE INSTALLING OR SERVICING

ONLY SPECIALIZED PERSONNEL SHOULD INSTALL THE EQUIPMENT AND ONLY

AFTER HAVING READ THIS USER'S GUIDE.

THE USER IS RESPONSIBLE FOR ANY PHYSICAL INJURY OR MATERIAL DAMAGE

RESULTING FROM MISHANDLING THE EQUIPMENT.

5-2. General

Terminal Connections

Use minimum of 75

°

C copper wire only for connections to ASTAT-IBP Plus terminals. The minimum wire size must conform to the 75

°

C

table according to applicable electrical codes. Tighten connections to the torque values given below. Supply conductors should have,

as a minimum, the same cross section as a full voltage starter.

A

A C

D

D C

SIGNAL

POWER

5. Installation

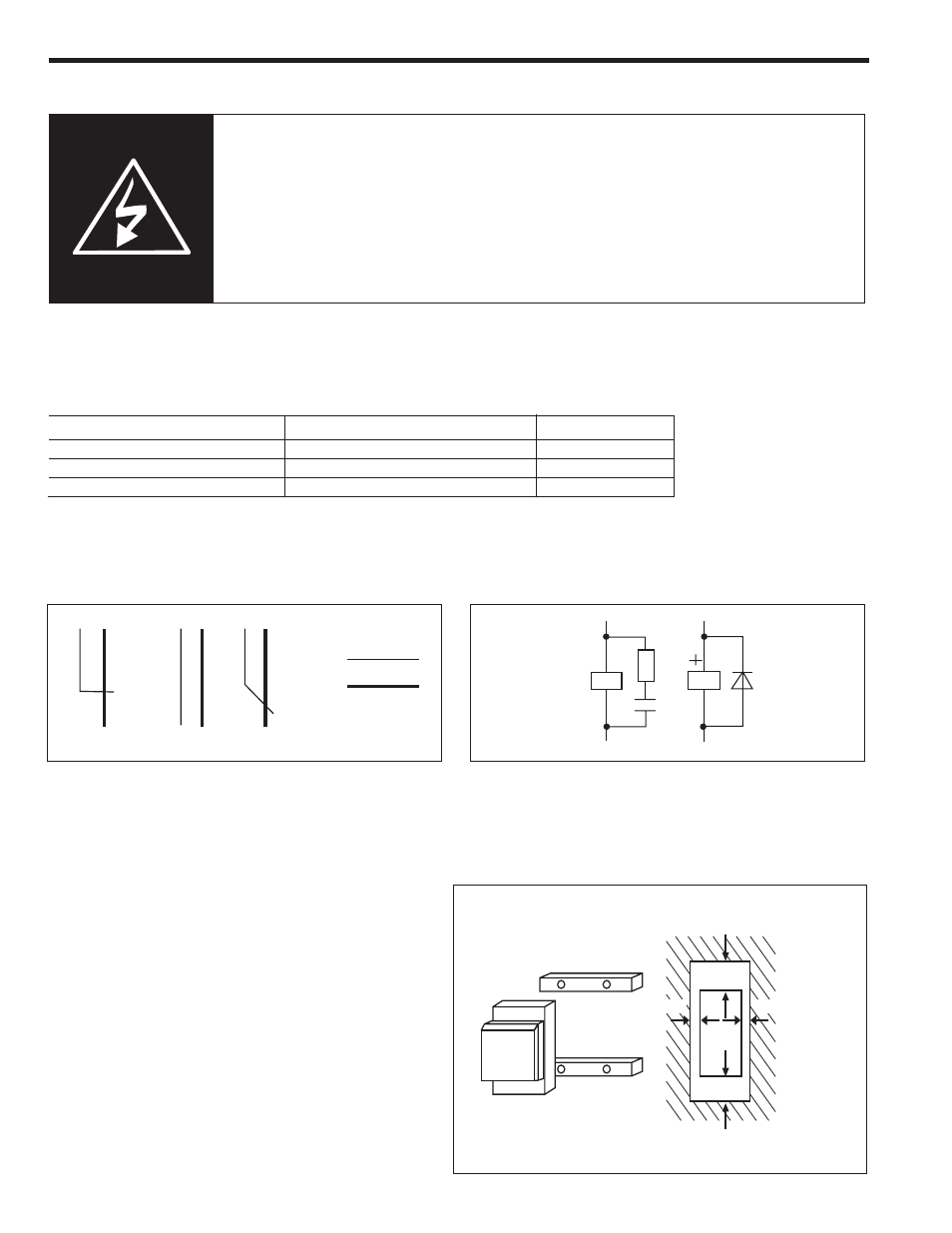

Environment

When installing equipment, keep the following points in mind:

- The equipment should be installed vertically and hang over a

platform or bars. The vertical position is essential for proper cool air

circulation.

- Environmental conditions are in accordance with the following

ranges and maximum values:

- Operating temperature: 0ºC to +55ºC

- Relative humidity (without condensation): 95%

- Maximum altitude: 3000m

Reduce rating by 1.5% / ºC from 40ºC and 1% / 100m from 1000m

- Do not install equipment in environments containing explosive or

flammable gases, or near important heat sources.

- Equipment should be well ventilated, with minimum keeping

clearances as indicated in the illustration.

- When equipment is to be mounted on a platform subject to strong

vibrations, there should be an elastic base to protect the equipment.

- When mounted in an enclosure, the temperature inside the enclosure

must be kept within the range of 0-45

°

C (32-113

°

F).

ASTAT

100mm

150mm

50mm

50mm

5-1

CORRECT

INCORRECT

10 cm

8 cm

Signal Wiring

Signal wiring should be no longer than 18 feet (up to 80 feet when

using shield cable). It must be separated from power wires (line,

motor, commands relays, etc.) by at least four inches and, if they

cross, they should do so at a 90

°

angle.

Coil Surge Suppression

Relays and contactors located in the same housing as the equipment

should have an RC suppressor parallel to the coil (or a reverse

diode, if controlled by DC).

Power Factor Capacitors

Do not install capacitors to correct the power factor between equipment output and motor.

Transformers

If the equipment is fed by a line transformer, its rated power should be at least 1.5 times, but less than 10 times, higher than equipment supply.