Astat-cd plus service instructions – GE Industrial Solutions ASTAT-CD Plus Solid-State Starters User Manual

Page 28

ASTAT-CD Plus Service Instructions

28

Step 26. SCR/Heat sink disassembly - Remove the

thermostat, mounting insulator and other

parts to allow disassembly of the clamps and

SCRs from the heatsinks (Figure 12).

SCR and heatsink

assembly

Clamp assembly

Mounting plate

Thermostat

Figure 12. SCR and heatsink assembly

CAUTION: Do not adjust or move the preset nut

(6) (Figure 13). The preset nut (6) and the bevel

washers under the cross piece (5) are preset to the

required force for assembly and clamping of the

new SCR to the heatsink.

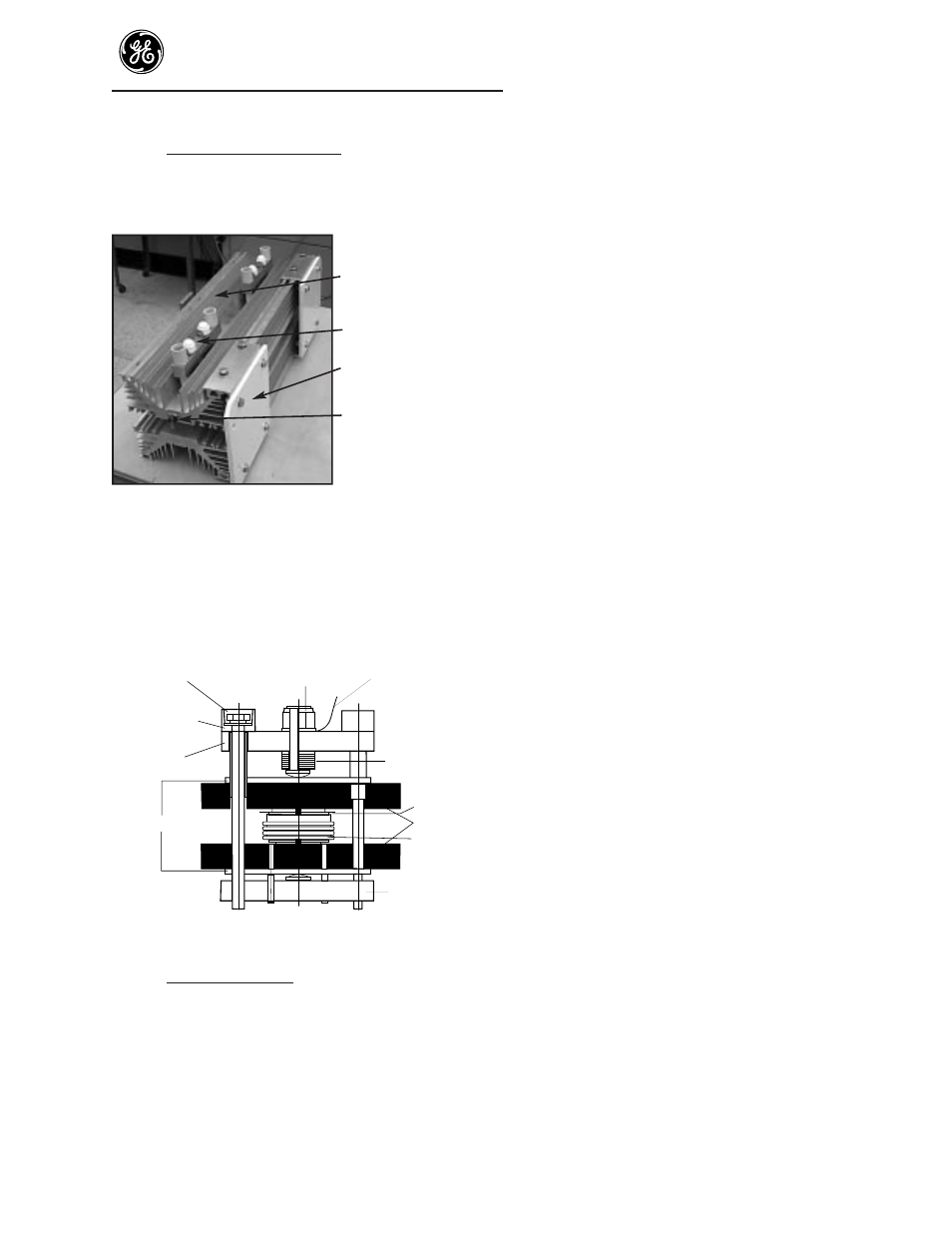

Figure 13. SCR and heatsink assembly

Step 27. Removing the SCRs (Figure 13) - Loosen the

tension bolts (10) alternately, 1/4 turn at a

time, on each SCR until pressure releases on

the SCRs. Remove bolts and clamps to release

the heatsinks. Note: record the position of

both SCRs (gate and cathode connectors on

the SCR) for reassembly.

Caution: Do not adjust or move the pre-set nut (6)

(Figure 13). The pre-set nut and the bevel washers

under the cross piece (5) are pre-set to the required

force for assembly and clamping of the new SCR to

the heatsink.

Note: The mounting surface of the heatsink

must be flat and clean (i.e., bare metal) and

the SCR surface must be clean. Thermal

compound must be coated on all mating

surfaces between the SCR and the heatsink.

Step 28. Clean both heat sink surfaces with a fine

abrasive such as Scotch brite, then remove all

particles from the surface of the heatsinks. To

clean the SCR, wipe the SCR with a mild

solvent.

Step 29. Apply a light coat of thermal compound such

as Electrolube 2GX to both sides of the SCR

and to both heatsink surfaces that mate to the

SCR.

Step 30. Make sure that the orientation of the SCR is

correct(as disassembled) and place the

contact face of the SCR over the locating pin

in the mating heatsink surface. Twist the SCR

backward and forward by hand applying firm

pressure to the SCR. Remove the SCR from

the heatsink, the mating surfaces must be

uniformly coated with thermal compound. If

the mating surfaces are not coated evenly,

apply slightly more thermal compound to the

surfaces and twist back and forth as before.

Step 31. With the 2 SCRs located properly on the

heatsink, i.e. the gate and cathode terminals

on the SCR must be on the proper side of the

heatsink assembly (as disassembled), place

the other heatsink over the SCRs. Refer to

figure 13.

The clamp is assembled so that the cross

piece(5) with the pressure plate(4) and the

tension bolts (10) are at the top. Underneath

the cross piece (3) with the pressure plate (4)

is put in position and the two tension bolts

(10) are alternately tightened carefully until a

slight resistance is felt. Check that both cross

pieces (3) and (5) are parallel. For this check,

it is sufficient to check that the tension bolts

project equal distances beyond the cross

piece(3). The tension bolts (10) may now be

alternately tightened 1/4 turn at time until

10 Tension bolt

4 Pressure plates

5 Cross piece

6 Pre-set nut

8 Metal gauge

7 Belleville washers

3 Cross piece

9 Center pin

1 Heatsinks

2 SCR

11 Insulated sleeve