Appendix g, Modbus protocol illustration – GE Industrial Solutions MX150_MX250 Modbus Network Card User Manual

Page 21

■

■ GE Zenith Controls

19 ■

■

MX150/MX250 Series Modbus Network Card (71R-2200)

Appendix G

For a detailed specification of the Modbus protocol,

reference the Modicon website address

www.modbus.org.

The Modbus protocol provides the internal standard for

parsing messages. During communications on a Modbus

network, the protocol determines how each slave will

know its device address, recognize a message addressed

to it, determine the kind of action to be taken, and

extract any data or other information contained in the

message. If a reply is required, the slave will construct the

reply message and send it using Modbus protocol.

The following is a brief description of the Modbus com-

mands supported by the Modbus Network Card. Each

command consists of the following:

•

a sample query message that is sent out by the

master device to the designated slave

•

the slave’s reply message to the master device

The query and reply messages show how the information

is packeted and sent out using the Modbus Protocol.

Each query message consists of the following:

•

Slave Address – address of the slave you wish to

establish communications with.

•

Function Code – code that lets the slave know what

command is being requested, e.g. read coil,

write single coil.

•

Starting Address High/Low Order – high and low

byte of the address the master reads from or

writes to. Coils and Registers are addressed start-

ing at 0. For instance Coil 1 is address 0 and

Register 40001 is address 0.

•

Error Check Field – contains either a

CRC

(

RTU

mode) or

LRC

(

ASCII

mode) error check value.

The query message for specific functions requires some

of the following information:

•

Number of Data Points High/Low Order – high

and low byte of the number of addresses the

master wants to read.

•

Data High/Low Order – high and low byte of the

data that will be written to the slave device.

•

Number of Coils High/Low Order – high and low

byte for the number of coils to force

ON

or

OFF

.

•

Number of Regs High/Low Order – high and low

byte for the number of registers to preset.

•

Byte Count – is the number of data bytes which

are sent to the slave.

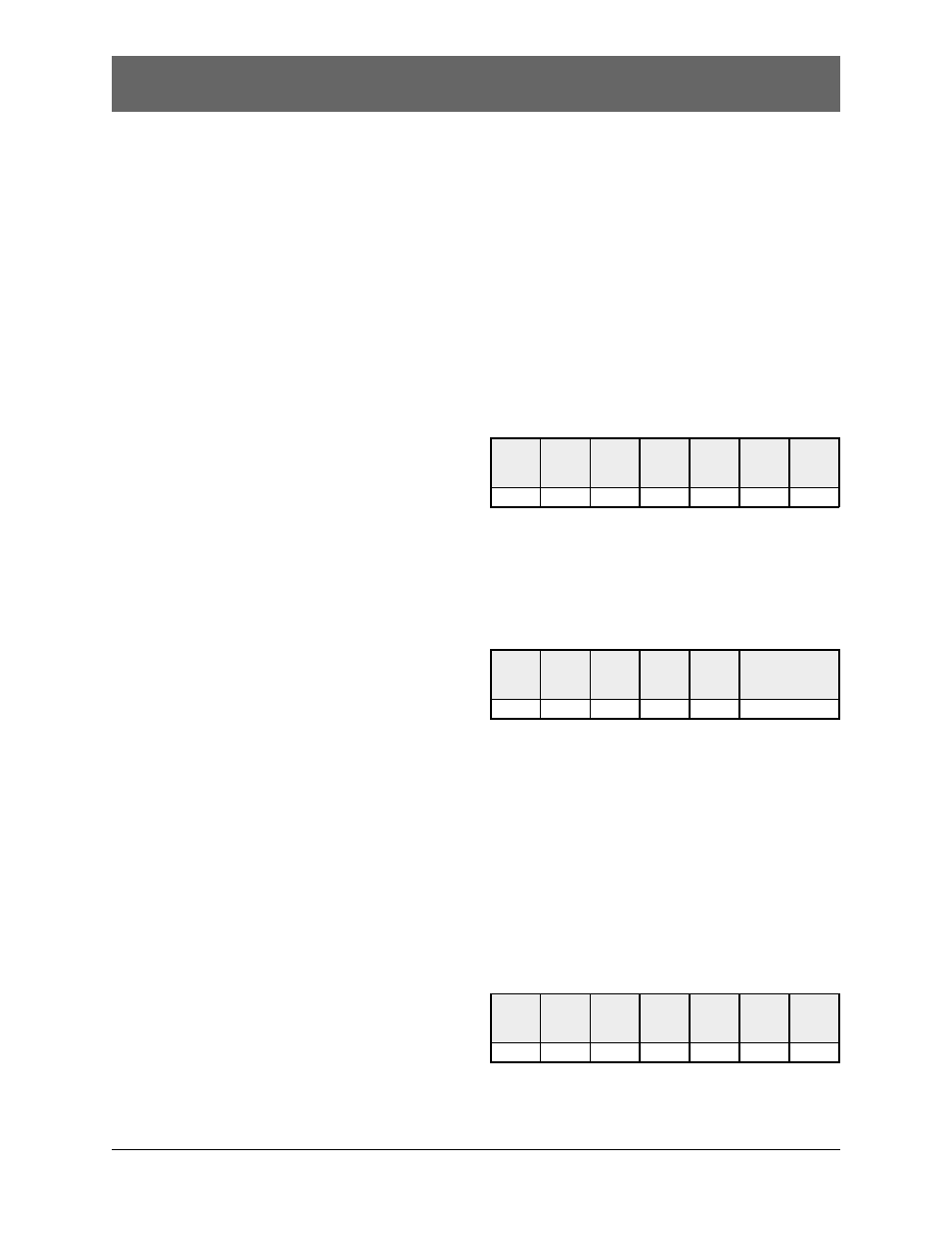

Slave

Address

05h

Figure G1 – Read Coil Status Query Message

Function

Code

Starting

Address

High Order

Starting

Address

Low Order

No. of Data

Points

High Order

No. of Data

Points

Low Order

Error

Check Field

(LRC or

CRC)

01h

00h

08h

00h

10h

—

Response

An example response to the Read Coil Status is shown

in Figure G2. The response includes the slave address,

function code, number of data bytes sent, the data,

and error checking.

The data consists of one bit per coil (1=

ON

, 0=

OFF

).

The status of coils 9-16 is C1 (hex) or 1100 0001 (binary).

Reading left to right, coils 16, 15, and 9 are

ON

and the

remainder is

OFF

. The other data byte is decoded similarly.

Slave

Address

05h

Figure G2 – Read Coil Status Response Message

Function

Code

Byte

Count

Data Coil

Status

9-16

Data Coil

Status

17-24

Error Check Field

(LRC or CRC)

01h

02h

C1h

A2h

—

Modbus Protocol Illustration

Read Coil Status (Function Code 01)

Query

This function allows the master device to obtain the

ON

/

OFF

bit status of various coils from the

addressed slave.

Figure G1 is a sample read coil status request to read

coils 9-24 (

MX

150/250 status bits) from slave device 5.

These query and reply messages are for both

RTU

and

ASCII

modes depending on whether the Error Check

Field contains a

CRC

or

LRC

respectively. Each value

in the query message is a hexadecimal value.

Read Holding Register (Function Code 03)

Read holding registers allows the master device to obtain

the binary contents of holding registers 4xxxx in the

addressed slave.

Query

Figure G3 is an example that reads registers

40006-40007 from slave 8.

Slave

Address

08h

Figure G3 – Read Holding Register Query Message

Function

Code

Starting

Address

High Order

Starting

Address

Low Order

No. of Data

Points

High Order

No. of Data

Points

Low Order

Error

Check Field

(LRC or

CRC)

03h

00h

05h

00h

02h

—